Preparation method for garnet type solid electrolyte material

A solid electrolyte, garnet-type technology, applied in the direction of circuits, electrical components, secondary batteries, etc., can solve the problems affecting the electrical performance of all-solid-state batteries, the thickness of the electrolyte sheet, etc., to achieve a small shape, low impedance, not easy to break Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] An embodiment of the present invention provides a method for preparing a garnet-type solid electrolyte material, comprising the following steps:

[0028] Step S1: Mix the garnet type electrolyte powder, binder and solvent to obtain electrolyte slurry.

[0029] The garnet type electrolyte is a garnet type lithium ion conductor, preferably, the garnet type lithium ion conductor includes Li 3 + x ln 3 Te 2-x m x o 12 , where 0≤x≤2, Ln is one or more of La, Y, Pr, Nd, Sm, Lu, etc., M is one or more of Nb, Ta, Bi, Sb, etc. May also include Li 5 + x ln 3-x A x m 2 o 12 , where 0≤x≤3, Ln is one or more of La, Y, Pr, Nd, Sm, Lu, etc., A is one or more of Mg, Ca, Sr, Ba, etc., M is One or more of Nb, Ta, Bi, Sb. can also include Li δ + x-3y ln 3-x A x m 2 B y o 12±λ Among them, δ and λ are positive integers, determined by the valence state of B element, 6≤δ≤7, 0≤λ≤1, 0≤x≤3, 0≤y≤2, Ln is La, Pr, Nd, Sm, One or more of Lu, etc., A is one or more of Mg, Ca, Sr,...

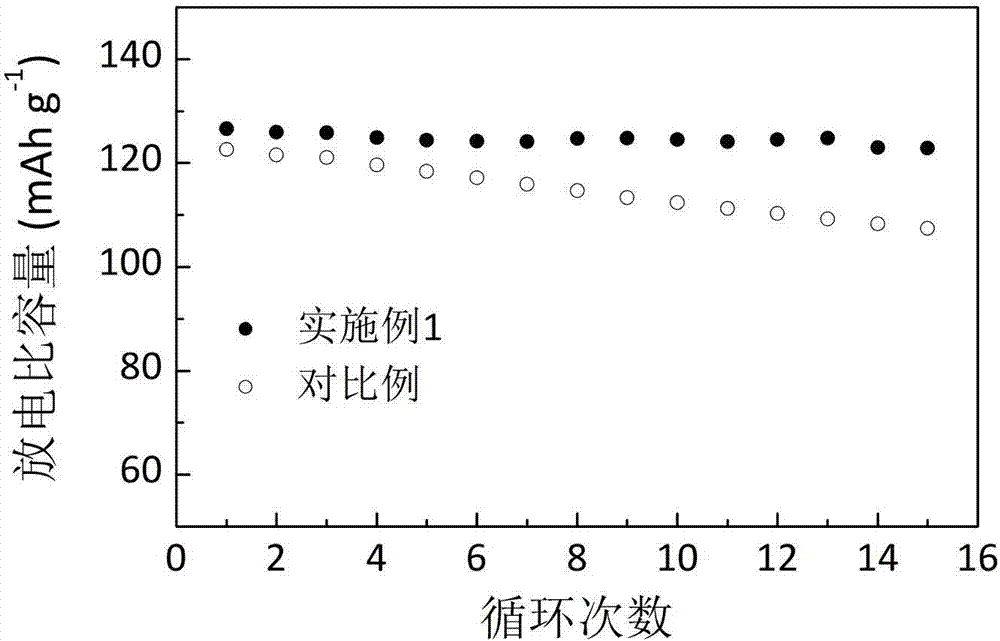

Embodiment 1

[0041] Dissolve PVB (polyvinyl butyral) in toluene to prepare a binder with a mass fraction of 10%. Then the garnet Li 7 La 3 Zr 2 o 12 (LLZO) Electrolyte powder is added to the binder. Using a dispersing emulsifier to stir and disperse the above electrolyte slurry evenly to obtain a uniform electrolyte slurry. The degassed electrolyte slurry is uniformly coated on a PET (polyethylene terephthalate) film by using an automatic coating machine to obtain a uniform and soft electrolyte film. The electrolyte film was removed from the PET film, and the film was cut into electrolyte sheets with a diameter of 25 mm. By pressing and firing, the cut electrolyte film was placed in an Ar gas-protected debinding box, and sintered at 1200 °C for 6 hours to discharge the binder in the electrolyte film and obtain a dense garnet-type Li 7 La 3 Zr 2 o 12 (LLZO) electrolyte sheet.

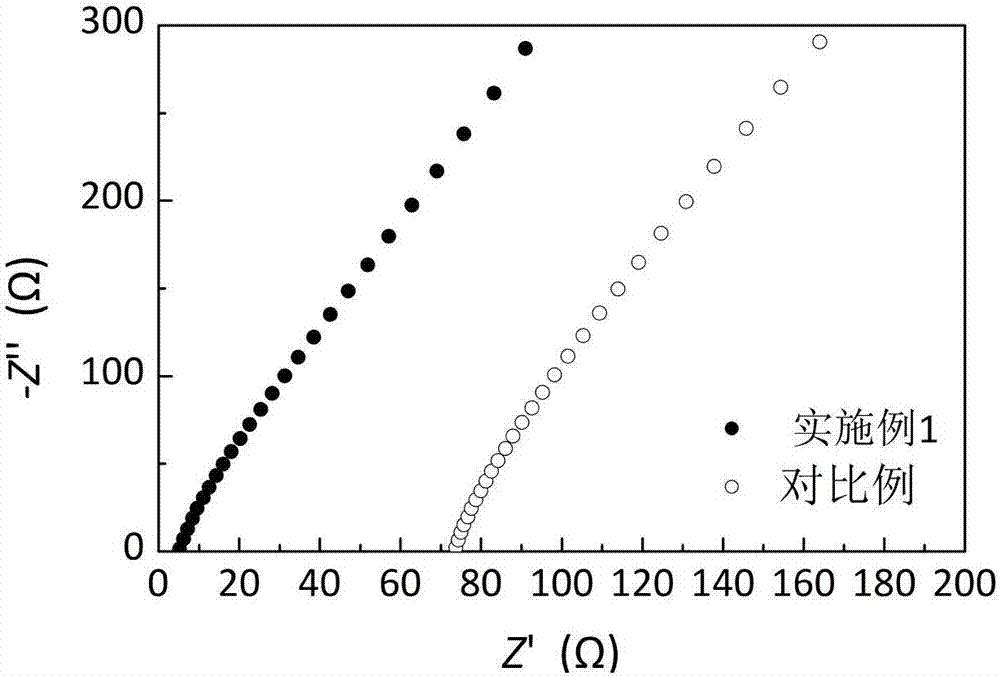

[0042] Use carbon as a blocking electrode to test its conductivity, and the AC impedance spectrum is as ...

Embodiment 2

[0044] PVDF (polyvinylidene fluoride) was dissolved in NMP (N-methylpyrrolidone) to prepare a binder with a mass fraction of 5%. Then the garnet Li 7 La 3 Zr 2 o 12 (LLZO) Electrolyte powder is added to the binder. Using a dispersing emulsifier to stir and disperse the above electrolyte slurry evenly to obtain a uniform electrolyte slurry. The degassed electrolyte slurry is uniformly coated on a PET (polyethylene terephthalate) film by using an AFA-II automatic film coating machine to obtain a uniform and soft electrolyte film. The electrolyte film was removed from the PET film, and the film was cut into electrolyte sheets with a diameter of 25 mm. By pressing and firing, the cut electrolyte film was placed in an Ar gas-protected debinding box, and sintered at 1000°C for 6 hours to discharge the binder in the electrolyte film and obtain a dense garnet-type Li 7 La 3 Zr 2 o 12 (LLZO) electrolyte sheet.

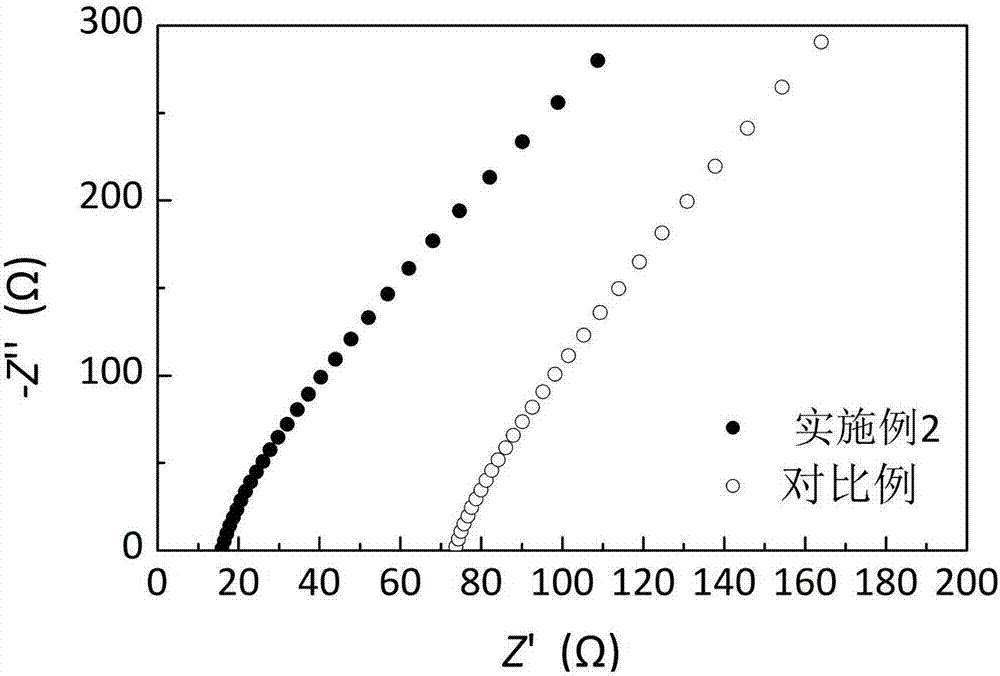

[0045] Use carbon as a blocking electrode to test its conductivi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com