Positive electrode active material coating liquid and preparation method therefor and positive electrode active material coating method

A positive electrode active material and coating technology, which is applied in the field of positive electrode active material coating, can solve the problems of uneven aluminum phosphate coating layer and poor cycle performance of lithium-ion batteries, so as to improve thermal stability and maintain battery capacity Performance, the effect of avoiding side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

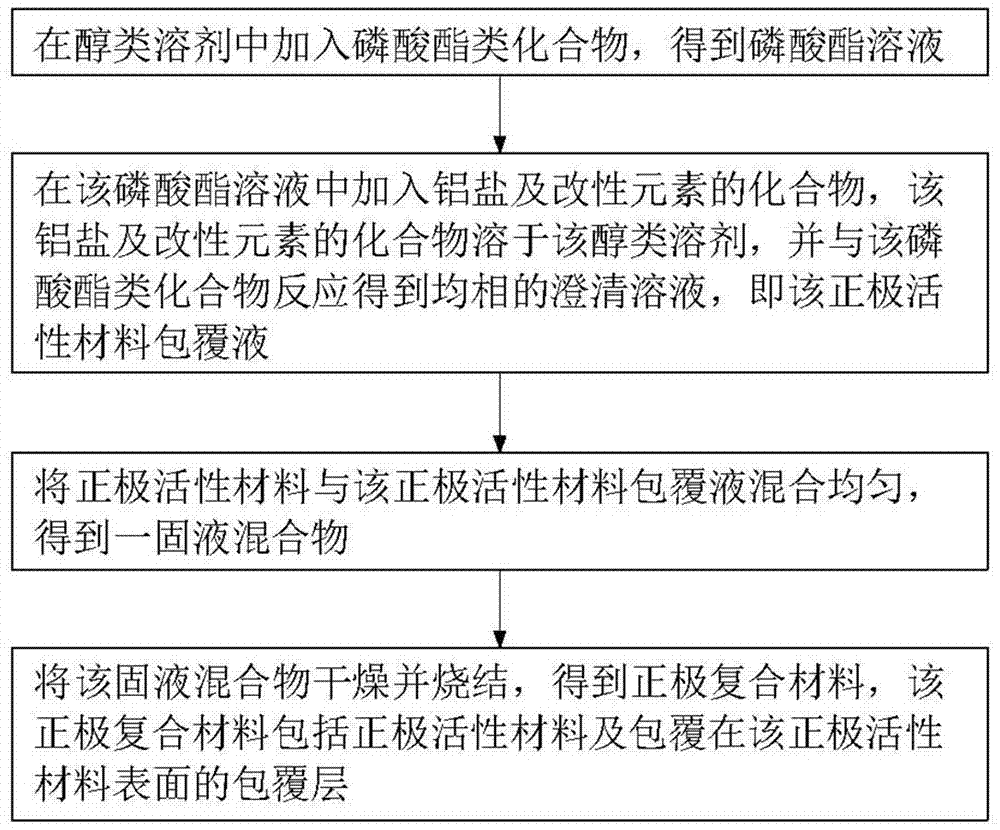

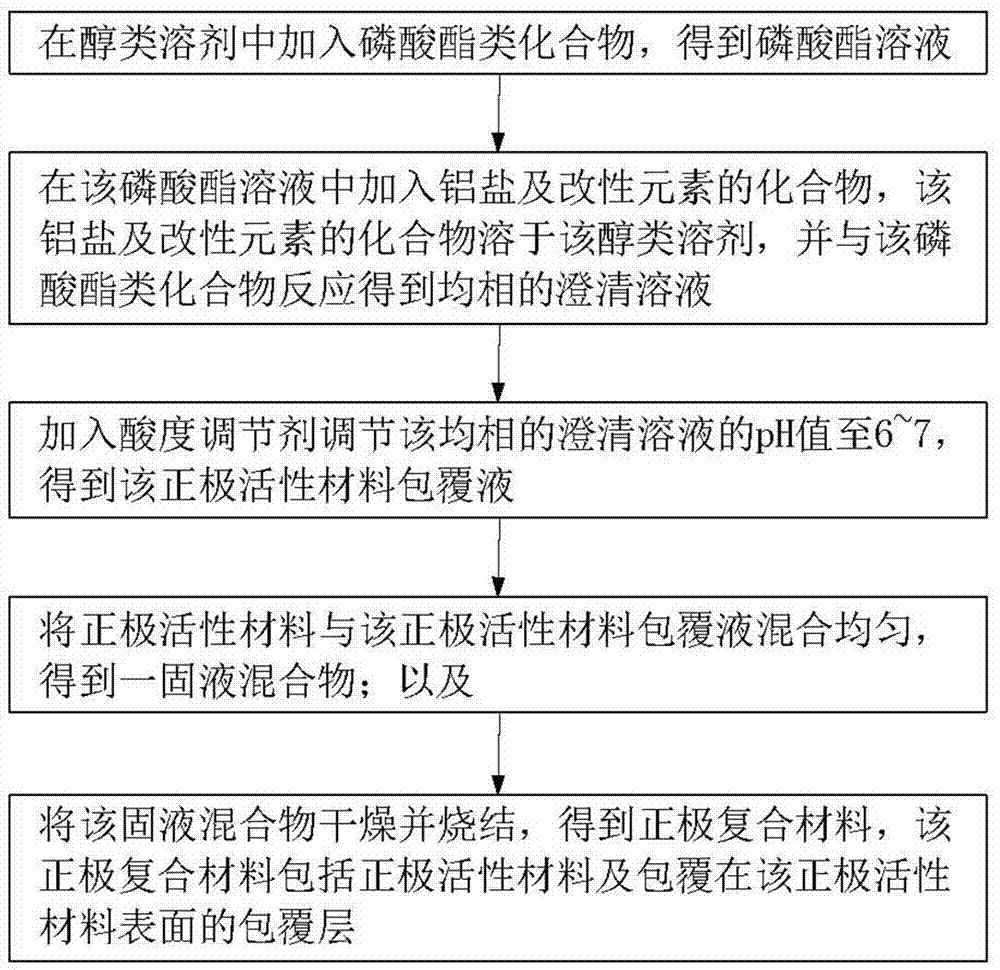

[0028] see figure 1 , the embodiment of the present invention further provides a method for preparing the above-mentioned positive electrode active material coating solution, the method comprising the following steps:

[0029] S1, adding a phosphoric acid ester compound to an alcoholic solvent to obtain a phosphoric acid ester solution; and

[0030] S2, adding an aluminum salt and a compound of a modifying element to the phosphate solution, the aluminum salt and a compound of a modifying element are dissolved in the alcohol solvent, and react with the phosphate compound to obtain a homogeneous clear solution, namely The cathode active material coating solution.

[0031] The alcohol solvent is preferably one or more composite solvents of methanol, ethanol, propanol, n-butanol and isopropanol.

[0032] The general formula of the phosphate compound can be A n P(O)(OH) m , wherein A is a carbon-oxyl group corresponding to the alcohol solvent molecule, such as at least one of m...

Embodiment 1

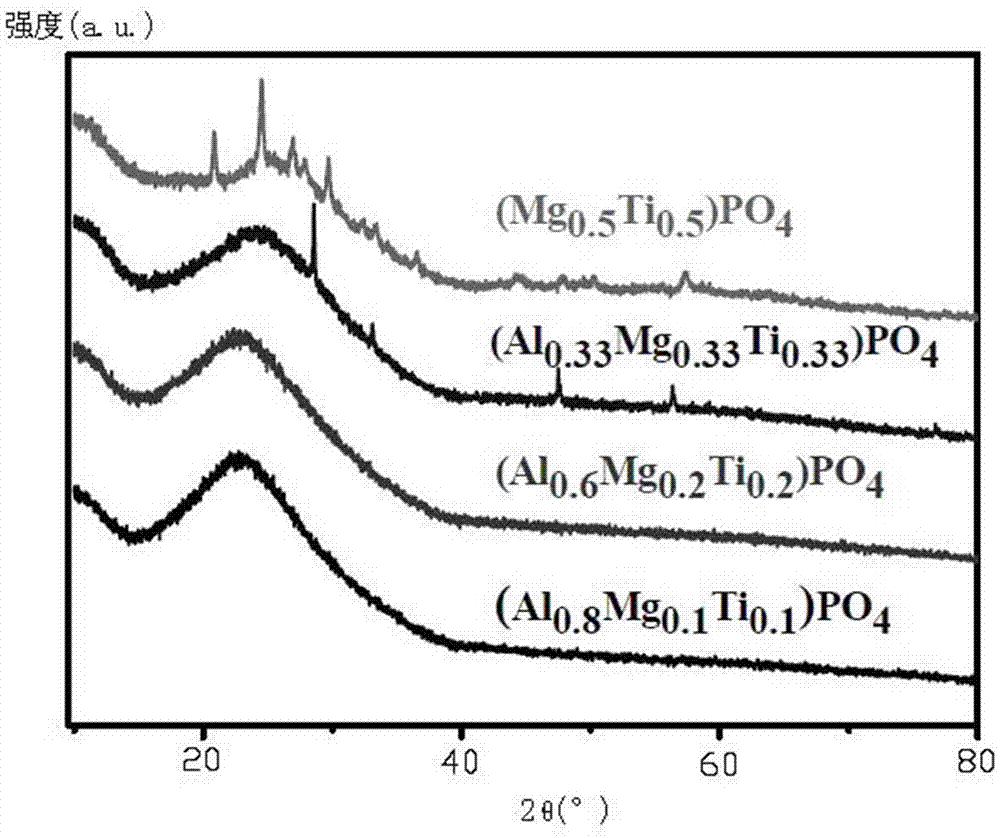

[0066] Mix phosphorus pentoxide and ethanol in a molar ratio of 1:10, stir at room temperature to completely react phosphorus pentoxide to form a phosphate solution; mix aluminum nitrate, magnesium acetate, and tetrabutyl titanate in a molar ratio of 8:1 : 1 is dissolved in ethanol to prepare a metal salt solution; the phosphate ester solution is mixed with the metal salt solution, and the molar ratio of P:M in the mixed solution of the phosphate ester and metal salt (M=Al+Mg+Ti) is 1:1 , stirred and reacted at 50° C. to obtain a homogeneous and clear cathode active material coating solution.

[0067] The positive electrode active material coating liquid and the positive electrode active material LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Mix according to the mass ratio of 1:5~1:2, filter the excess liquid phase, dry at 60°C and then sinter in the air at 400°C to obtain the positive electrode composite material and assemble the lithium-ion battery. The electrolyte in the lithium-ion batte...

Embodiment 2

[0070] Same as Example 1, the only difference is that the molar ratio of aluminum nitrate, magnesium acetate and tetrabutyl titanate is 6:2:2, the coating solution is dried and the XRD test results of the sintered product are as follows image 3 of (Al 0.6 Mg 0.2 Ti 0.2 )PO 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com