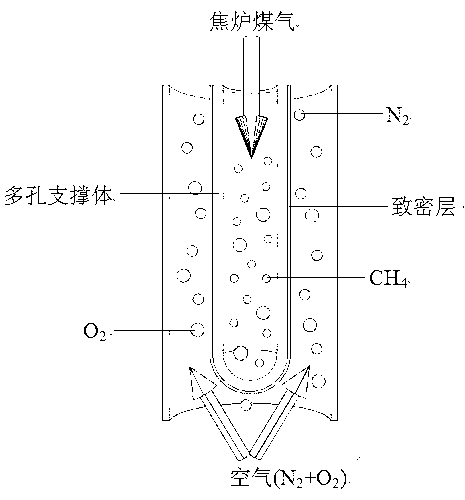

Preparation method of tubular asymmetric oxygen-permeable membrane

An asymmetric membrane, asymmetric technology, applied in the field of functional ceramic materials, can solve the problems of small oxygen permeable area of sheet membrane, lack of practical application value, etc., to solve the matching problem of chemical compatibility and thermal expansion coefficient, sintering shrinkage rate Consistent, thin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

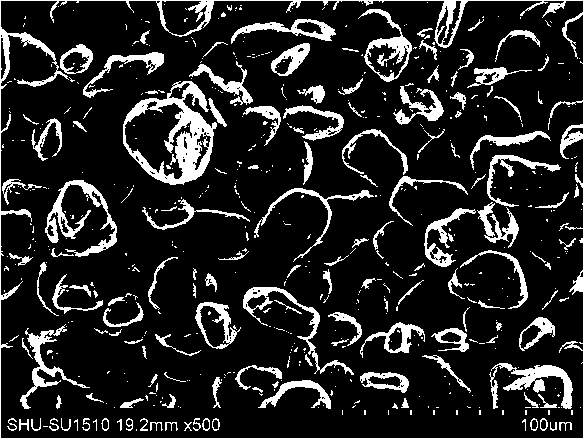

Embodiment 1

[0033] (1) Preparation of BCFN powder: BaCo 0.7 Fe 0.2 Nb 0.1 o 3-x (BCFN) powders were prepared by traditional solid-phase synthesis. First, the BaCO according to the stoichiometric ratio 3 、Co 3 o 4 , Fe 2 o 3 and Nb 2 o 5 The powders (both with a purity greater than 99%) were uniformly mixed by ball milling for 48 h (dry mixing), and the mixture was cold isostatically pressed at 75 MPa, and then solid-phase synthesized at 950 °C, crushed, sieved (40 mesh), and then 72 h Fine grinding (wet grinding) so that the average particle size of BCFN powder reaches 1 μm, and the obtained powder after drying will be used as the matrix material of the porous support and the dense layer in the preparation of the asymmetric membrane.

[0034] (2) Preparation of pore-forming agent: Spheroidal graphite is selected as the pore-forming agent, and the average particle size of graphite after sieving is 25 μm. Surface modification of graphite, immerse graphite in an aqueous solution o...

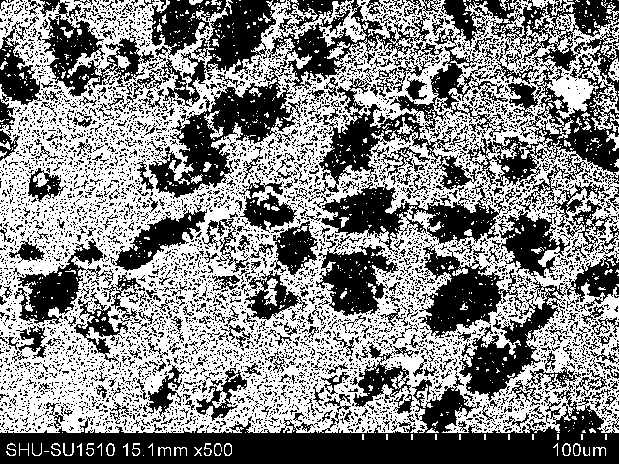

Embodiment 2

[0038] (1) Preparation of BCFN powder: BaCo 0.7 Fe 0.2 Nb 0.1 o 3-x (BCFN) powders were prepared by traditional solid-phase synthesis. First, the BaCO according to the stoichiometric ratio 3 、Co 3 o 4 , Fe 2 o 3 and Nb 2 o 5 The powders (both with a purity greater than 99%) were uniformly mixed by ball milling for 48 h (dry mixing), and the mixture was cold isostatically pressed at 75 MPa, and then solid-phase synthesized at 950 °C, crushed, sieved (40 mesh), and then 72 h Fine grinding (wet grinding) so that the average particle size of the BCFN powder reaches 2 μm, and the obtained powder after drying will be used as the matrix material of the porous support and the dense layer in the preparation of the asymmetric membrane.

[0039] (2) Preparation of pore-forming agent: Spheroidal graphite was selected as the pore-forming agent, and the average particle size of graphite after sieving was 27 μm. Surface modification of graphite, immerse graphite in an aqueous solu...

Embodiment 3

[0043] (1) Preparation of BCFN powder: BaCo 0.7 Fe 0.2 Nb 0.1 o 3-x (BCFN) powders were prepared by traditional solid-phase synthesis. First, the BaCO according to the stoichiometric ratio 3 、Co 3 o 4 , Fe 2 o 3 and Nb 2 o 5 The powders (both with a purity greater than 99%) were uniformly mixed by ball milling for 48 h (dry mixing), and the mixture was cold isostatically pressed at 75 MPa, and then solid-phase synthesized at 950 °C, crushed, sieved (40 mesh), and then 72 h Fine grinding (wet grinding) so that the average particle size of BCFN powder reaches 3 μm, and the obtained powder after drying will be used as the matrix material of the porous support and the dense layer in the preparation of the asymmetric membrane.

[0044] (2) Preparation of pore-forming agent: Spheroidal graphite is selected as the pore-forming agent, and the average particle size of graphite after sieving is 30 μm. Surface modification of graphite, immerse graphite in aqueous solution of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com