Electrochemical method for preparing hydroxylapatite granule thin coating on metallo-implantation surface

A technology of hydroxyapatite and implants, which is applied in coatings, prostheses, medical science, etc., can solve the problems of large hydroxyapatite particles, low metal binding force, and difficult control, and achieve uniform thickness, It is not easy to fall off and has the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Electrolyte composition:

[0028] Elements of Hap: Ca(NO 3 ) 2 ---0.3mM / L,

[0029] NH 4 h 2 PO 4 ---0.18mM / L,

[0030] pH=5;

[0031] Additive: Na 3 C 6 h 5 o 7 2H 2 O---0.3mM / L

[0032] Conductive agent: NaNO 3 ---0.01M / L

[0033] Electrolyte temperature: 30°C

[0034] Deposition time: 0.5 hours

[0035] Deposition voltage: 2V

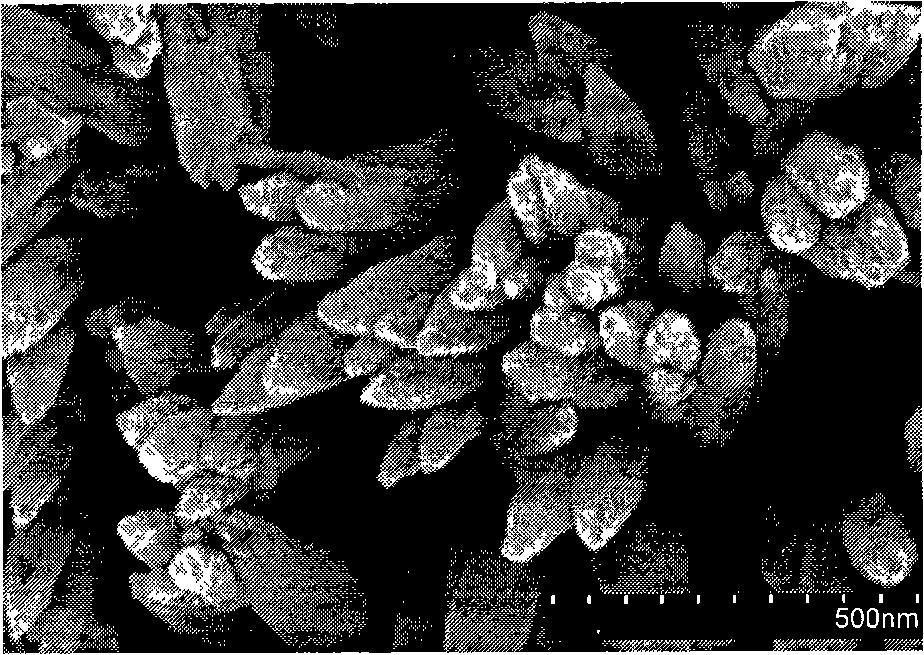

[0036] A uniform thin coating of hydroxyapatite particles is obtained on the surface of metal titanium. The Hap particles are conical, and the diameter gradually decreases from the bottom to the top. The top diameter is about 50nm and the length is about 150nm. figure 1 And attached figure 2 shown.

Embodiment 2

[0038] Electrolyte composition:

[0039] Hap constituent elements: C 6 h 10 CaO 6 ---6mM / L,

[0040]NH 4 h 2 PO 4 ---3.6mM / L,

[0041] pH=12;

[0042] Additive: Na 3 C 6 h 5 o 7 2H 2 O---60mM / L

[0043] Conductive agent: C 3 h 5 NaO 3 ·5H 2 O---1M / L

[0044] Electrolyte temperature: 95°C

[0045] Deposition time: 5 hours

[0046] Deposition voltage: 4V

[0047] Above-mentioned electrolyte composition is made up of physiological ion completely, got rid of nitrate ion (NO in example 1 3 - ) may have adverse effects on biocompatibility. A uniform thin coating of hydroxyapatite particles is obtained on the surface of metal titanium. The Hap particles are irregular columns with a diameter of about 150nm and a rough surface. image 3 And attached Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com