Lithium electrode and lithium secondary battery comprising same

A lithium electrode and current collector technology, which is applied in the field of lithium electrodes, can solve the problems of adverse effects on battery performance and different lithium forms, and achieve the effect of making up for easy cracking, thin and uniform thickness, and preventing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

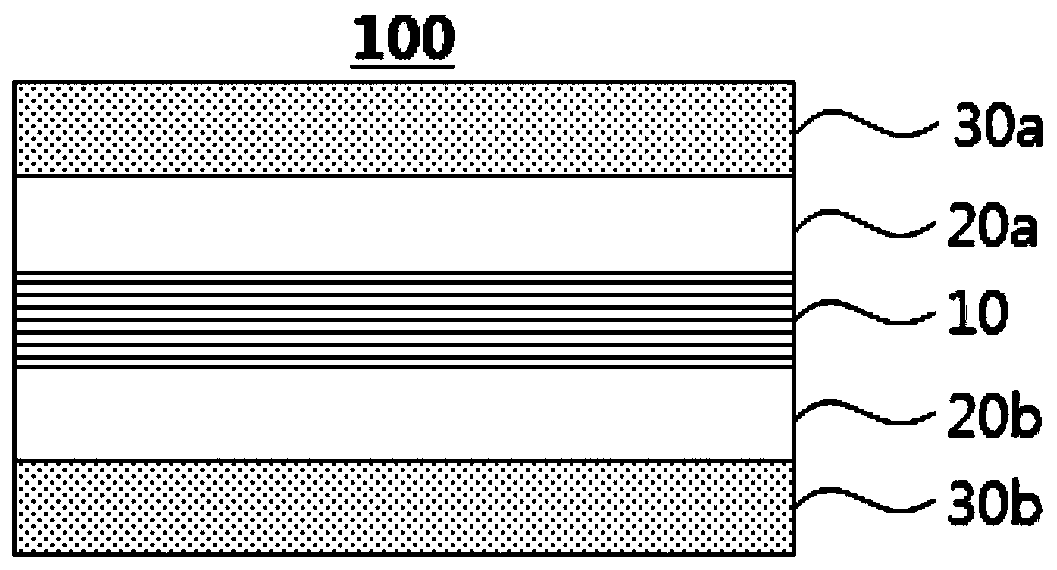

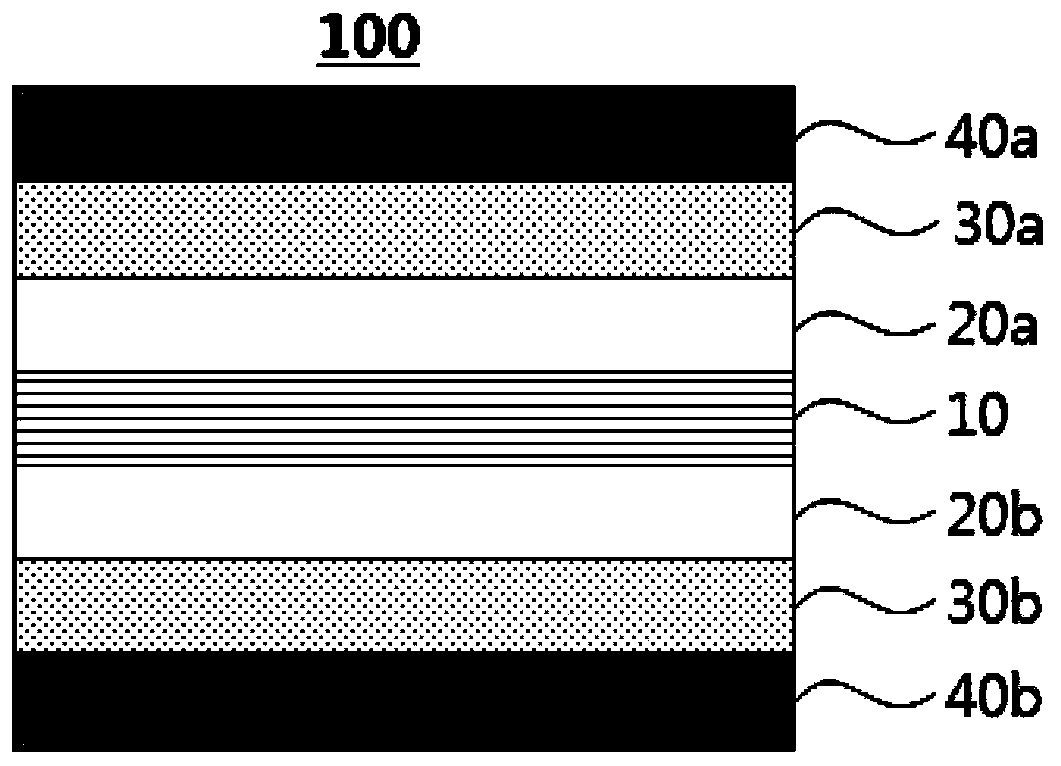

[0139] Embodiment 1: the manufacture of lithium electrode

[0140] A release PET film (SKC Haas, RX12G50 μm) having release layers on both surfaces was prepared as a base material.

[0141] A PVDF-HFP coating solution was prepared as a coating solution for forming a protective layer for protecting lithium metal on one side of the substrate. PVDF-HFP coating solutions were prepared by dissolving PVDF-HFP (Arkema, LBG grade) in NMP solvent as a 5% solution.

[0142] The PVDF-HFP coating solution was coated on one side of the release PET film at a thickness of 0.2 μm using a micro-gravure coater to form a PVDF-HFP protective layer.

[0143] Lithium metal was deposited on the protective layer by vapor deposition at a temperature of 600° C. to form a lithium metal layer having a thickness of 20 μm, and the above-mentioned release PET film, PVDF-HFP protective layer, and lithium metal layer were sequentially stacked. The structure was wound at a speed of 1 m / min. Two stacked stru...

Embodiment 2

[0147] Embodiment 2: the manufacture of lithium electrode

[0148] A PVDF protective layer was formed in the same manner as in Example 1 except that PVDF was used instead of PVDF-HFP as a polymer for forming the protective layer.

Embodiment 3

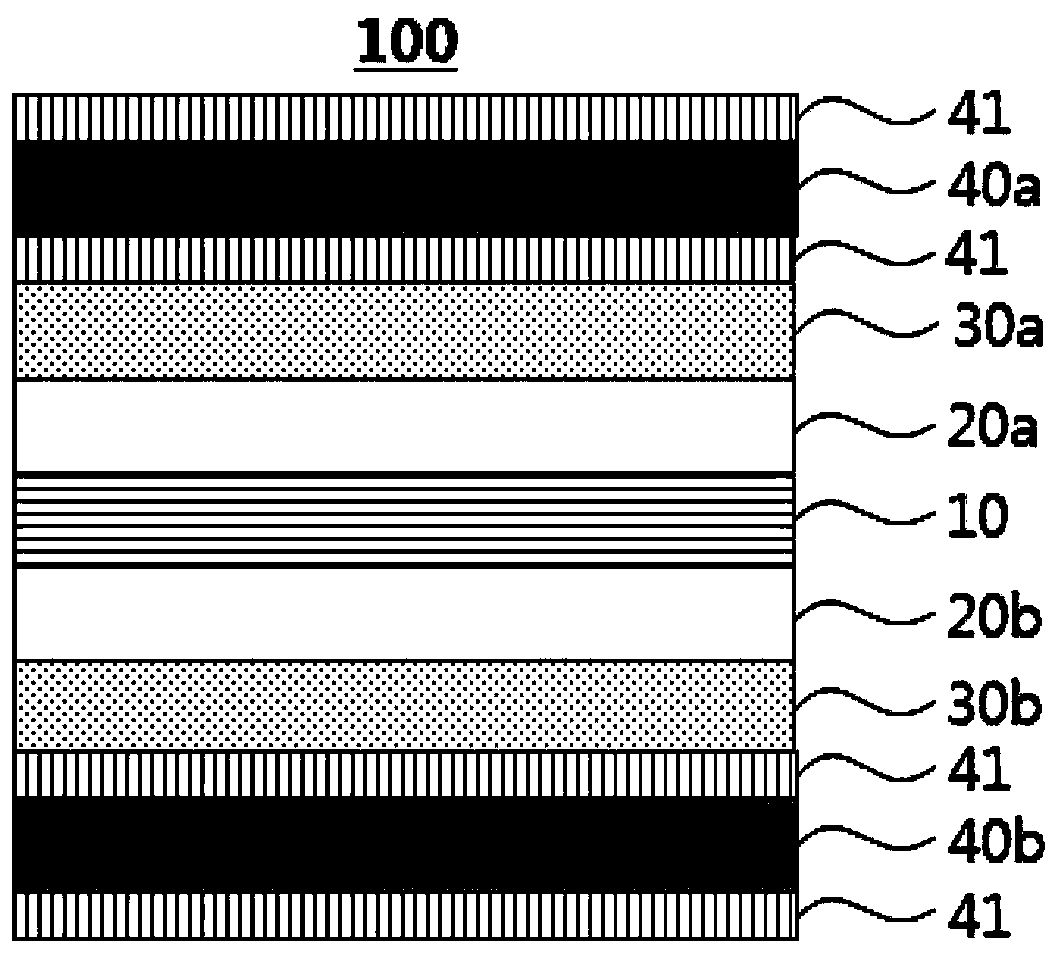

[0149] Embodiment 3: the manufacture of lithium electrode

[0150] A lithium electrode was fabricated in the same manner as in Example 1 except for using a current collector having SiO coatings on both sides thereof.

[0151] At this time, in order to form the SiO coating, a mixture of SiO and graphite at a weight ratio of 1:1 was dissolved in an ethanol solvent to form a coating solution having a concentration of 1M.

[0152] The coating solution was coated on both sides of the current collector with a thickness of 80 μm using a slot die coater to form a SiO coating layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com