Film sensor for measurement of heat flow in high temperature environment and manufacturing method thereof

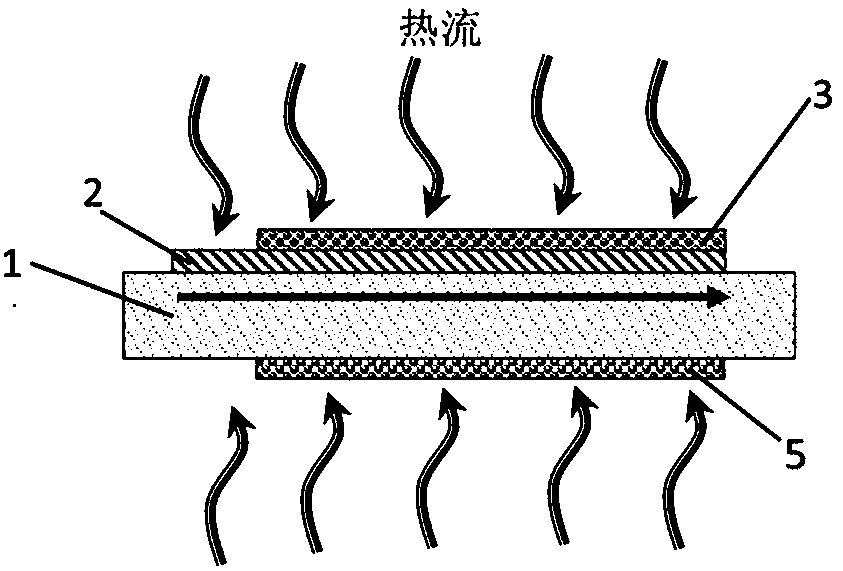

A thin-film sensor, high-temperature environment technology, applied in calorimeters, measuring heat, measuring devices, etc., can solve the problems of complicated sensor lead manufacturing process, long response time, and difficult to distinguish and read signals, and achieve stable reading. , increased sensitivity, thickness and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

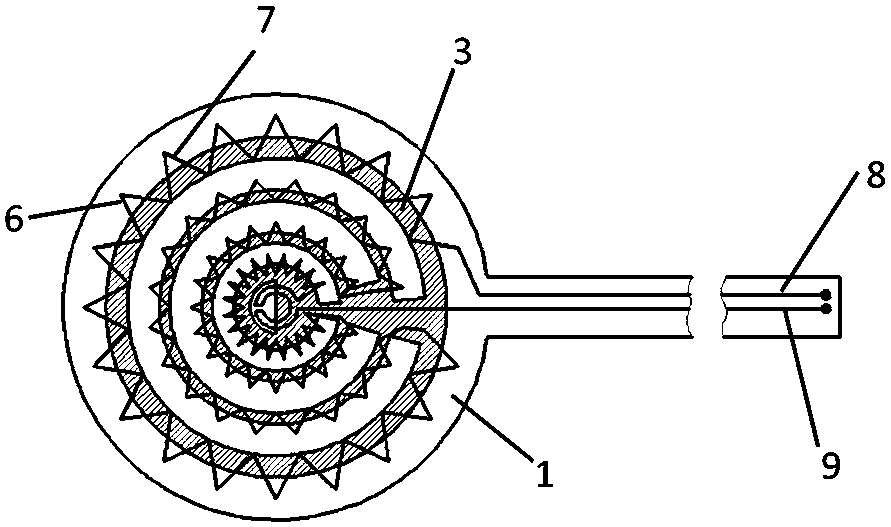

Embodiment 1

[0026] The thermocouple stack 2 is made of platinum-platinum-rhodium 10 thermocouple, the positive lead-out electrode 9 is made of platinum, and the negative lead-out electrode 8 is made of platinum-rhodium 10 .

Embodiment 2

[0028] The material selected for the thermocouple stack 2 is gold-gold-palladium thermocouple, the material selected for the positive lead-out electrode 9 is gold, and the material selected for the negative lead-out electrode 8 is gold-palladium.

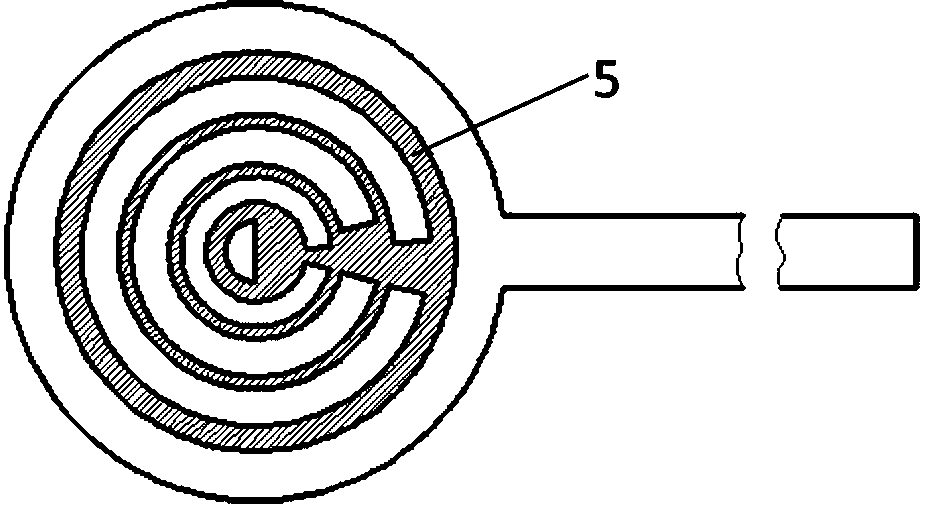

[0029] Such as Figure 4 As shown, the present invention also provides a method for manufacturing a thin film sensor for measuring heat flow in a high temperature environment, comprising the following steps:

[0030] a. Polish the surface layer of the micron-sized ceramic substrate, and screen-print the pattern of the positive thermocouple and the positive lead-out electrode on it with a corresponding screen, and then heat up to 100°C for drying;

[0031] b. On the surface layer of the micron-sized ceramic substrate, use the corresponding screen to screen-print the pattern of the negative thermocouple and the negative lead-out electrode, and then heat up to 100°C for drying;

[0032] c. Use the corresponding mask plate to align abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com