Device assembly for manufacturing radial tire inner liner component

A radial tire and airtight layer technology, which is applied in the field of rubber tire processing, can solve the problems of inconsistent inner liner inner liner thickness, decreased tire safety performance, increased tire thickness and weight, etc., to improve the raw rubber strength and deformation resistance , Reduce the amount of rubber used, improve the accuracy and performance of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

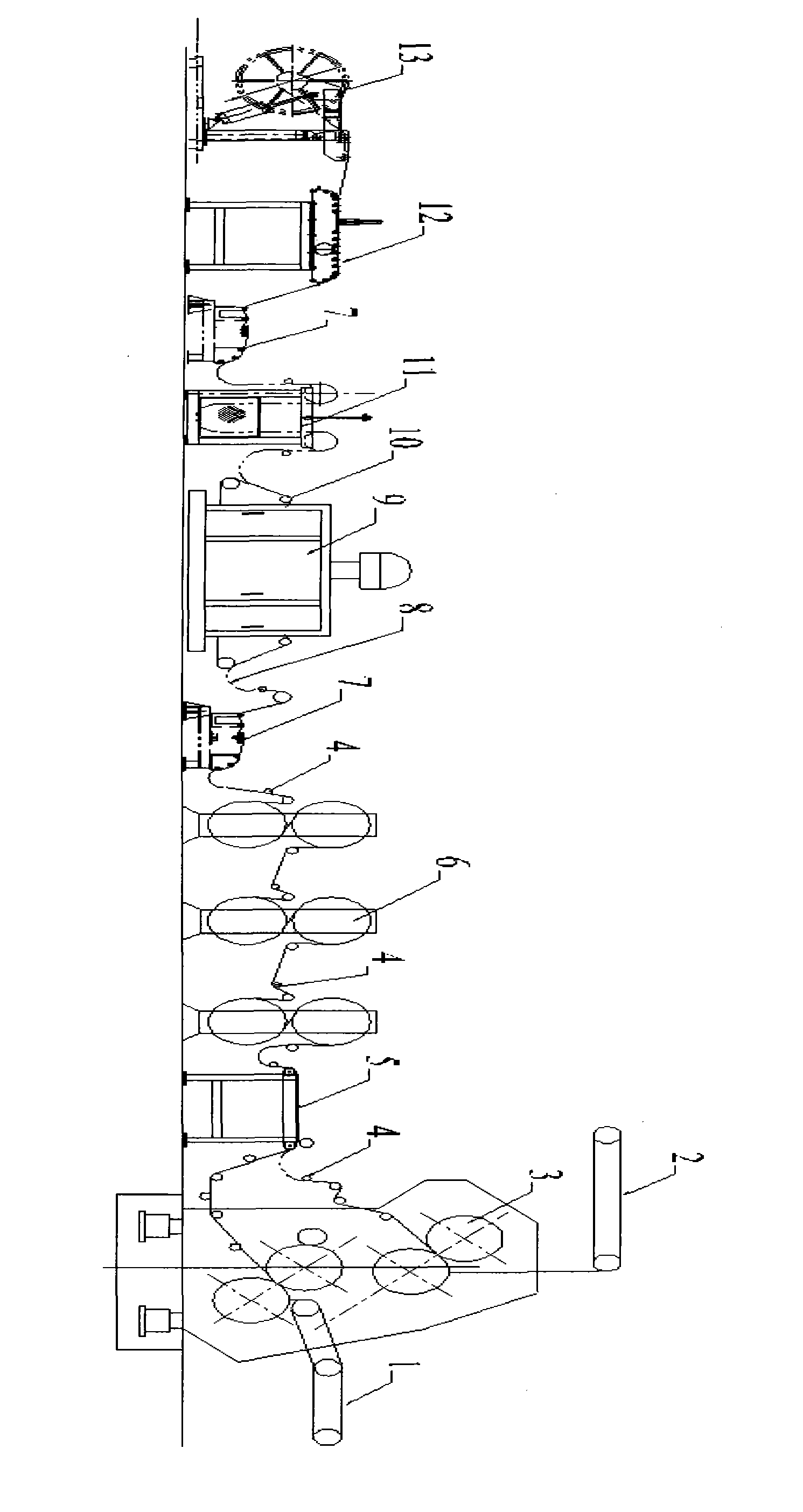

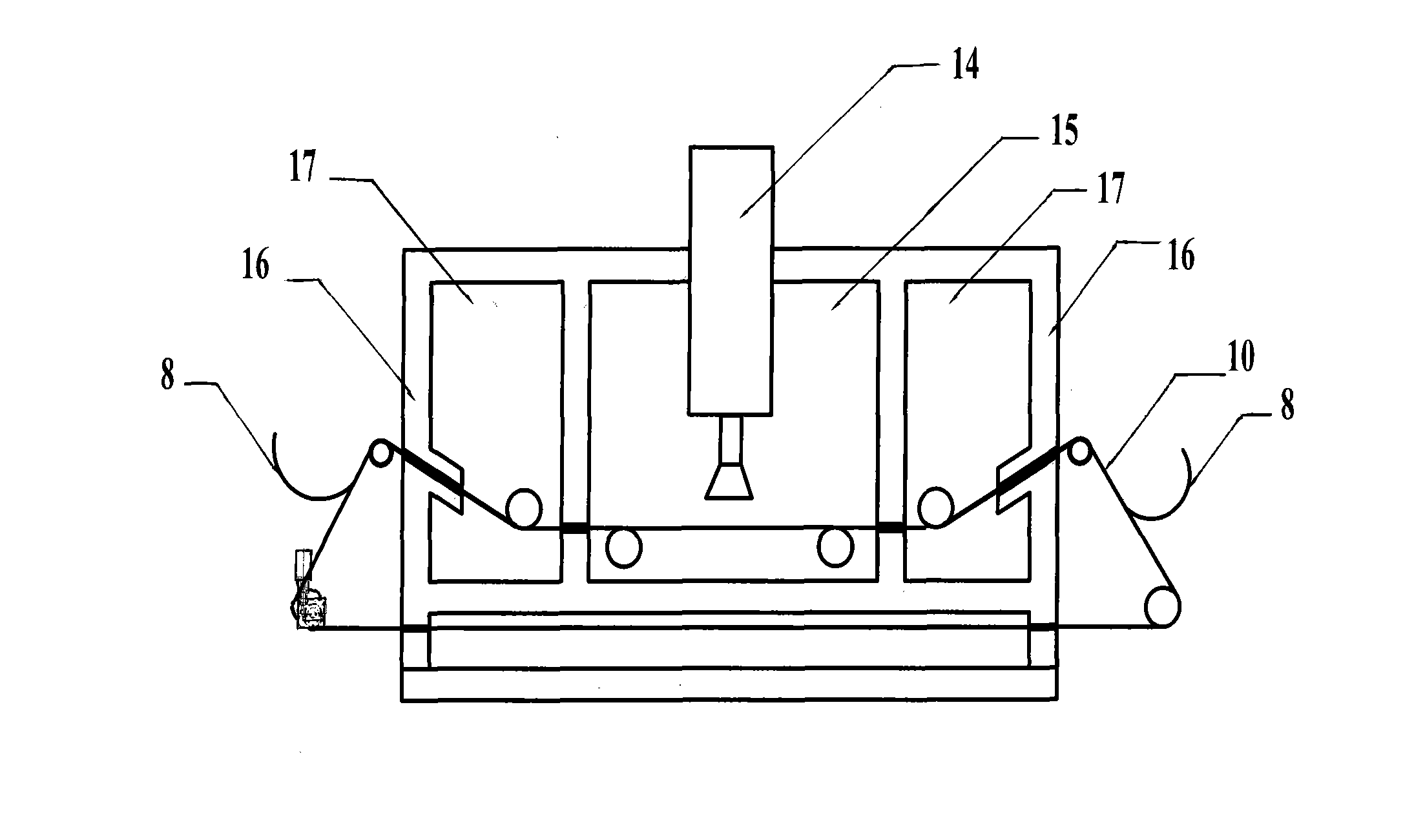

[0012] Attached below figure 1 and attached figure 2 Describe the present invention in detail, a device assembly for manufacturing inner liner parts of radial tires, including a main glue supply device 1, an auxiliary glue supply device 2, a four-roll calender 3, a floating roller speed regulating device 4, a bonding conveying Device 5, cooling device 6, automatic deviation correction device 7, self-shielding irradiation device 9, under-beam transmission device 10, film storage device 11, slicing device 12 and double coiling device 13, the rubber raw rubber is passed through the main rubber supply device 1 And the auxiliary glue supply device 2 is sent into the four-roll calender 3, the speed of the four-roll calender 3 is the main control speed, and the speed control device is composed of PLC, floating roller speed adjustment device and DC motor to coordinate the work, and at the same time, it is supplemented by multiple The speed buffer device adjusts the speed accordingly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com