Horizontal shell-and-plate falling film anti-scale evaporator and application method thereof

A horizontal plate and evaporator technology, which is applied in the field of horizontal tube falling film evaporators, can solve problems such as liquid film splashing, achieve the effects of preventing droplet splashing, reducing occupied space, and improving interface flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

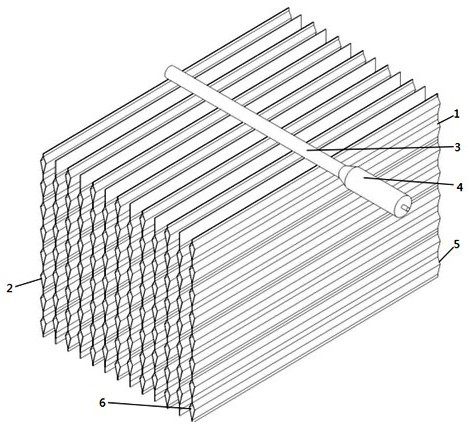

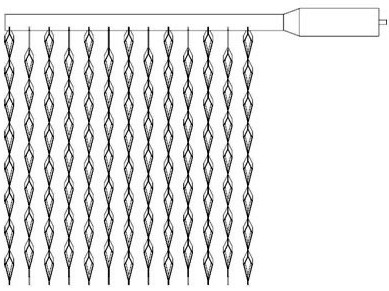

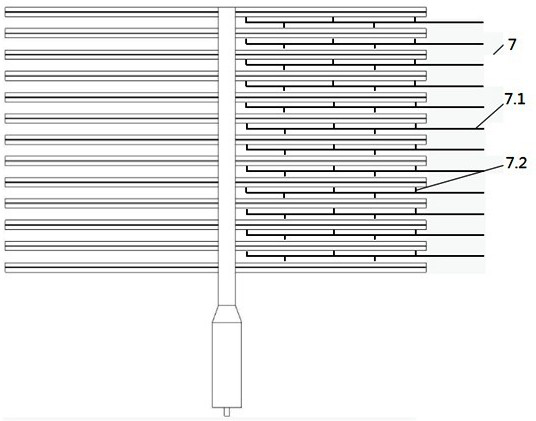

[0043] Such as Figure 1 to Figure 3 As shown, the present invention discloses a horizontal plate and shell type falling film anti-fouling evaporator, which includes several heat transfer plates 1 arranged parallel to each other and vertically juxtaposed to form a heat transfer plate bundle, each heat transfer plate There are several connected diamond-shaped cavities 2 on both sides of the sheet 1, and the diamond-shaped cavities 2 between adjacent heat transfer plates 1 are arranged alternately up and down. When the area of the diamond-shaped cavities 2 of the evaporator is large, it is necessary to increase the installation of ultrasonic The quantity of the vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com