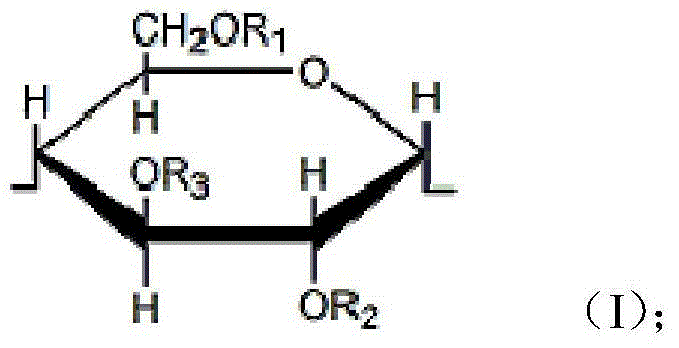

Dual-modified maltodextrin high efficiency water reducing agent and preparation method thereof

A high-efficiency water reducer and maltodextrin technology, applied in the field of concrete admixtures, can solve the problems of useless by-products, oxidation, etc., and achieve the effect of good water solubility and great advantages in water reducing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

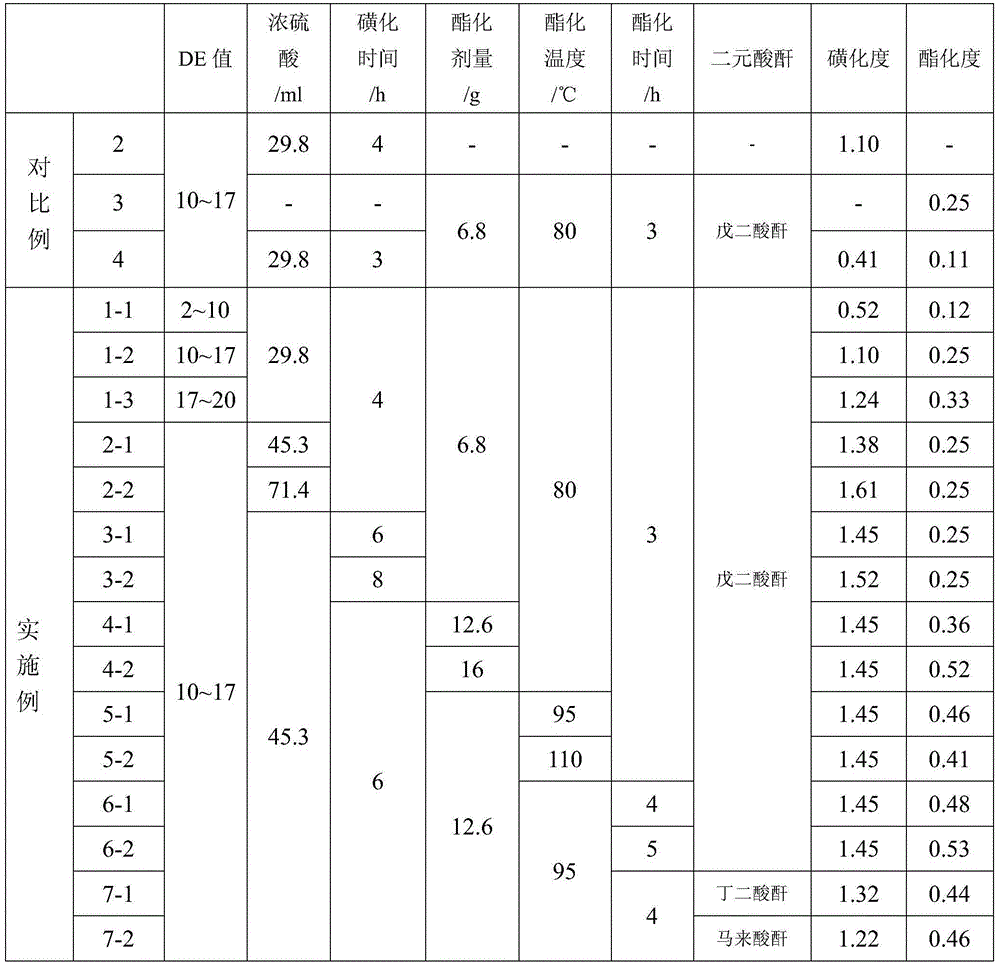

Embodiment 1-1

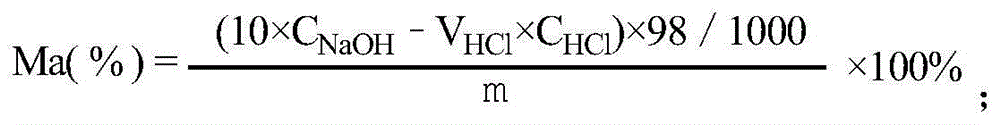

[0030] Add 0.56mol concentrated sulfuric acid into the reaction vessel, and place it in a constant temperature tank at -2°C (±2°C), then add 0.45mol ethanol dropwise to the reaction vessel with a constant pressure funnel, and keep stirring during the dropping process to prevent Local overheating, the whole dropping process takes 0.5h, then add 0.1mol maltodextrin with DE value of 2 to 10 into the mixture of concentrated sulfuric acid and ethanol, react for 4h, wash, filter, and vacuum dry to obtain sulfonated dextrin. Take 0.1 mol of the prepared sulfonated dextrin and 0.06 mol of glutaric anhydride and put them into another reaction vessel, mix them evenly, and then react at 80°C for 3 hours, then end, and finally dissolve the product in water and neutralize with alkali to obtain double-modified malt Dextrin superplasticizer.

Embodiment 1-2

[0032] Except that the maltodextrin whose DE value is 2-10 is adjusted to the maltodextrin whose DE value is 10-17, the others are the same as Example 1-1.

Embodiment 1-3

[0034] Except that the maltodextrin with a DE value of 10-17 is adjusted to the maltodextrin with a DE value of 17-20, the others are the same as in Example 1-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of esterification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com