Table top material increasing and decreasing wood-plastic composite 3D printer with abrasive machining function

A 3D printer and grinding processing technology, which is applied in the field of desktop wood-plastic 3D printers, can solve the problems of shape accuracy, size accuracy, surface quality, single-layer printing thickness and plane printing accuracy limitations, and improve processing and manufacturing efficiency. , the expansion of the operation process, and the effect of high surface processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

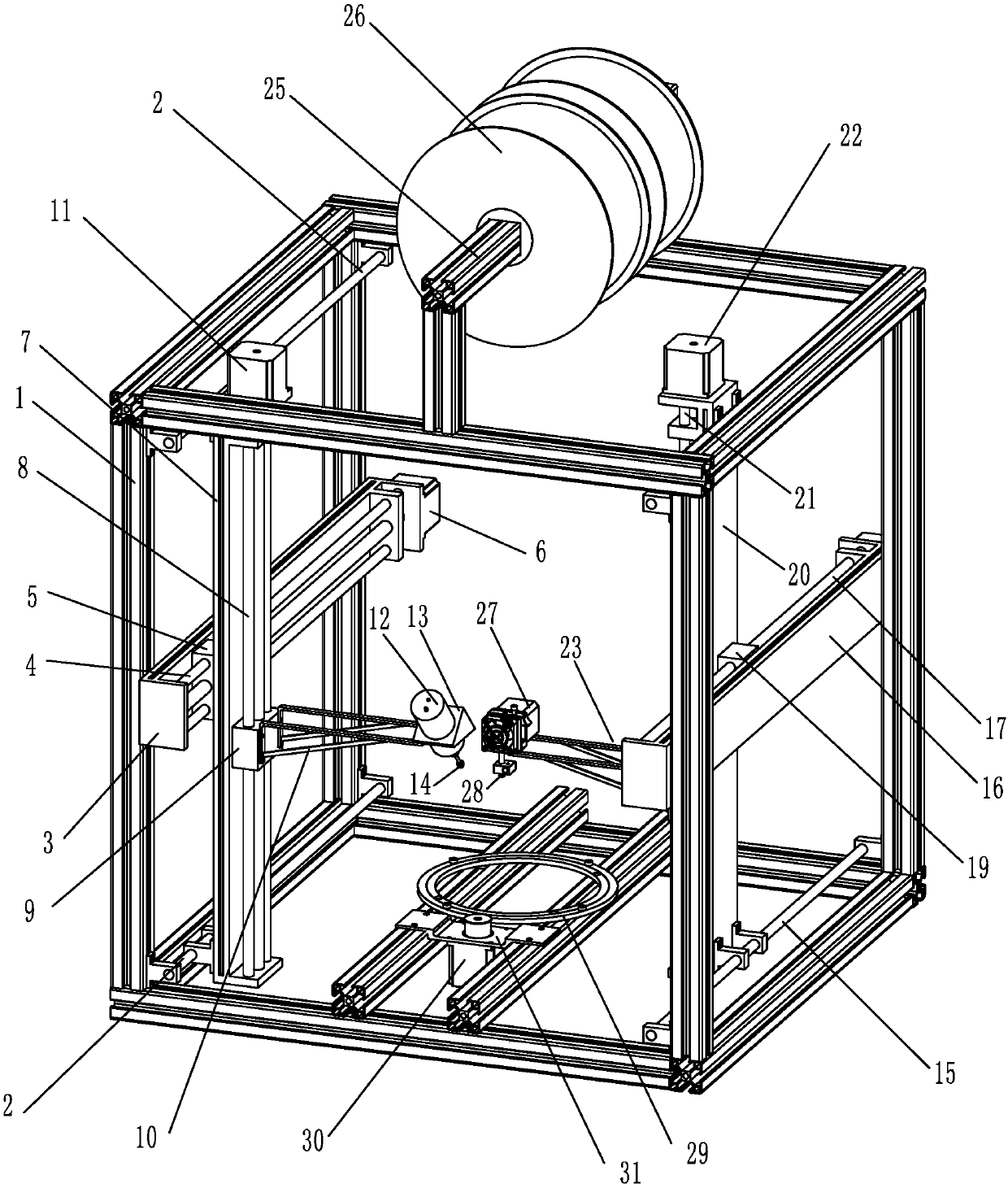

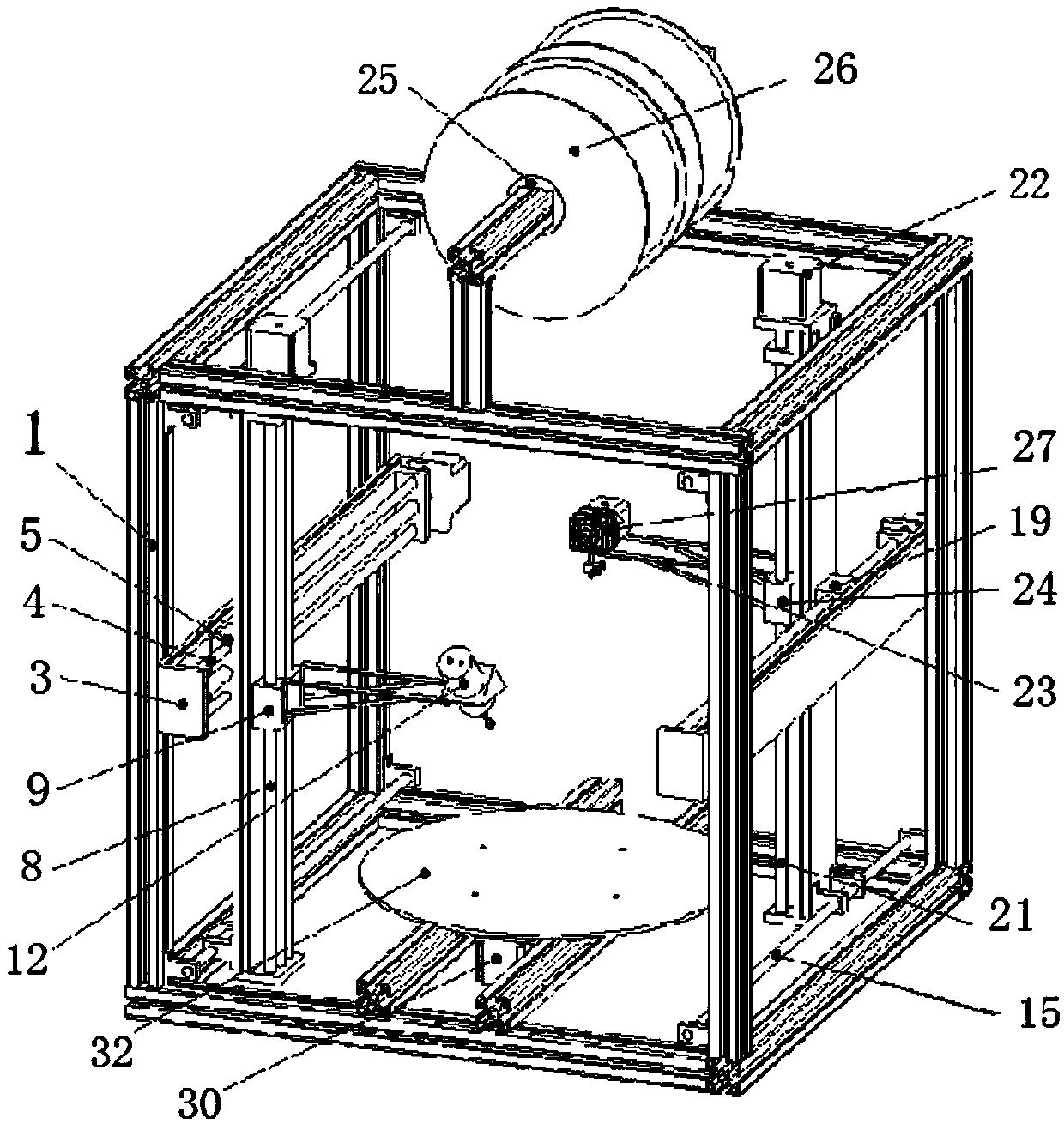

[0022] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a desktop wood-plastic 3D printer with a grinding function, including a rectangular frame 1, characterized in that it also includes a material reduction component, an additive component, and a material increase and decrease work platform , the adding and subtracting material working platform is rotatably installed on the lower end of the rectangular frame 1, and the material subtracting component and the adding material component are installed on the rectangular frame 1 respectively;

[0023] The material reduction component includes two material reduction slide rails 2, material reduction X-axis guide rail 3, material reduction X-axis screw 4, material reduction X-axis screw slide table 5, material reduction X-axis motor 6, and material reduction Z-axis guide rail 7 , material reduction Z-axis lead screw 8, material reduction Z-axis slide table 9, material reduction support fram...

specific Embodiment approach 2

[0031] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, the grinding assembly of this embodiment includes a grinding motor 12, a grinding frame 13 and a grinding tool head 14, the grinding frame 13 is installed on the material reduction support frame 10, and the grinding motor 12 is installed on the grinding On the frame 13, the output end of the grinding motor 12 is connected with the grinding head 14. With such a setting, it is convenient to more flexibly realize grinding on the outer contour of the product after the material is added, so as to improve the processing accuracy of the product. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Specific implementation mode three: combination figure 1 and figure 2 To illustrate this embodiment, the additive component of this embodiment includes two additive guide rods 15, additive X-axis guide rails 16, additive X-axis screw 17, additive X-axis motor 18, and additive X-axis slide 19 , additive Z-axis guide rail 20, additive Z-axis lead screw 21, additive Z-axis motor 22, additive support frame 23, additive Z-axis sliding table 24 and additive printed parts, additive X-axis guide rail 16 horizontal installation In the middle of the other side of the rectangular frame 1, the additive X-axis motor 18 is installed on the end of the additive X-axis guide rail 16, the additive X-axis lead screw 17 is installed on the additive X-axis guide rail 16, and the additive X-axis The output end of the motor 18 is connected to the additive X-axis screw 17, and the additive X-axis slide 19 is installed on the additive X-axis screw 17; two additive guide rods 15 are horizontal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com