Method for preparing composite fibers in ionic liquid medium

An ionic liquid and composite fiber technology, which is applied in fiber treatment, plant fibers, animal fibers, etc., can solve the problems of low grafting rate and low degradability of composite fibers, and achieve the effects of improving grafting rate and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

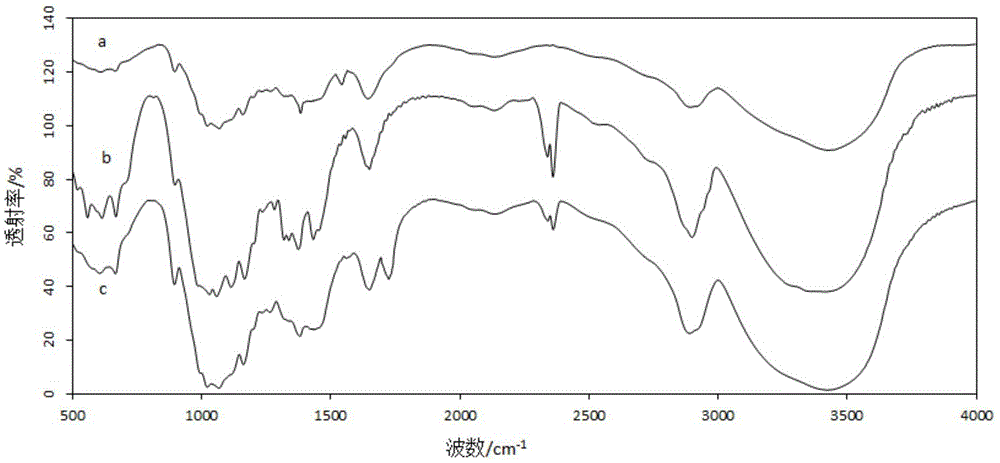

Image

Examples

Embodiment 1

[0023] (1) Take an appropriate amount of microcrystalline cellulose in a beaker and dry at 80°C for 4-6 hours.

[0024] (2) Take 5ml of ionic liquid ([EMIM][DEP]) and 5ml of nitric acid solution with a mass percentage concentration of 65wt%-68wt%, add them to a 30ml glass bottle successively, and then add 0.15g of dried micro Crystalline cellulose and 0.15g NaNO 2 For powder, heat in an oil bath in a collector-type constant temperature heating magnetic stirrer and assisted by magnetic stirring, and react at a constant temperature of 70°C for 1-2h; after the reaction is completed, use deionized water three times the volume of the mixed solution of nitric acid and ionic liquid to slowly add And carry out suction filtration and washing 5-7 times until the pH value of the filtrate is 6-7, and dry at 80° C. for 24 hours to obtain carboxycellulose.

[0025] (3) Take 3.75g of ionic liquid ([EMIM][DEP]) and 0.15g of carboxy cellulose and add it to a 20ml iodine measuring bottle a, an...

Embodiment 2

[0033] (1) Take an appropriate amount of microcrystalline cellulose in a beaker and dry at 80°C for 4-6 hours.

[0034] (2) Take 5ml of ionic liquid ([EMIM][DEP]) and 5ml of nitric acid solution with a mass percentage concentration of 65wt%-68wt%, add them to a 30ml glass bottle successively, and then add 0.15g of dried micro Crystalline cellulose and 0.15g NaNO 2 For powder, heat in an oil bath in a collector-type constant temperature heating magnetic stirrer and assisted by magnetic stirring, and react at a constant temperature of 70°C for 1-2h; after the reaction is completed, use deionized water three times the volume of the mixed solution of nitric acid and ionic liquid to slowly add And carry out suction filtration and washing 5-7 times until the pH value of the filtrate is 6-7, and dry at 80° C. for 24 hours to obtain carboxycellulose.

[0035] (3) Take 3.75g of ionic liquid ([EMIM][DEP]) and 0.15g of carboxy cellulose and add it to a 20ml iodine measuring bottle a, an...

Embodiment 3

[0043] (1) Take an appropriate amount of microcrystalline cellulose in a beaker and dry at 80°C for 4-6 hours.

[0044] (2) Take 5ml of ionic liquid ([BMIM][Cl]) and 5ml of nitric acid solution with a mass percentage concentration of 65wt%-68wt%, and add them to a 30ml glass bottle successively, and then add 0.15g of dried microbes to the bottle successively. Crystalline cellulose and 0.15g NaNO 2 Powder, heated in an oil bath and magnetically stirred in a collector-type constant temperature heating magnetic stirrer, and reacted at a constant temperature of 90°C for 1-2h; after the reaction was completed, slowly added deionized water three times the volume of the mixed solution of nitric acid and ionic liquid and Suction filtration and washing for 5-7 times until the pH value of the filtrate is 6-7, and drying at 60°C for 24 hours to obtain carboxycellulose.

[0045] (3) Get 3.75g ionic liquid ([BMIM][Cl]) and 0.15g carboxycellulose and add successively in the 20ml iodine mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com