Preparation method of modified cellulose heavy metal adsorbent

A technology of cellulose and heavy metals, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of resource waste, environmental pollution, etc., and achieve convenient operation, strong adsorption capacity, The effect of cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

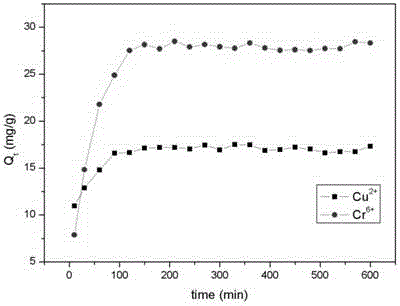

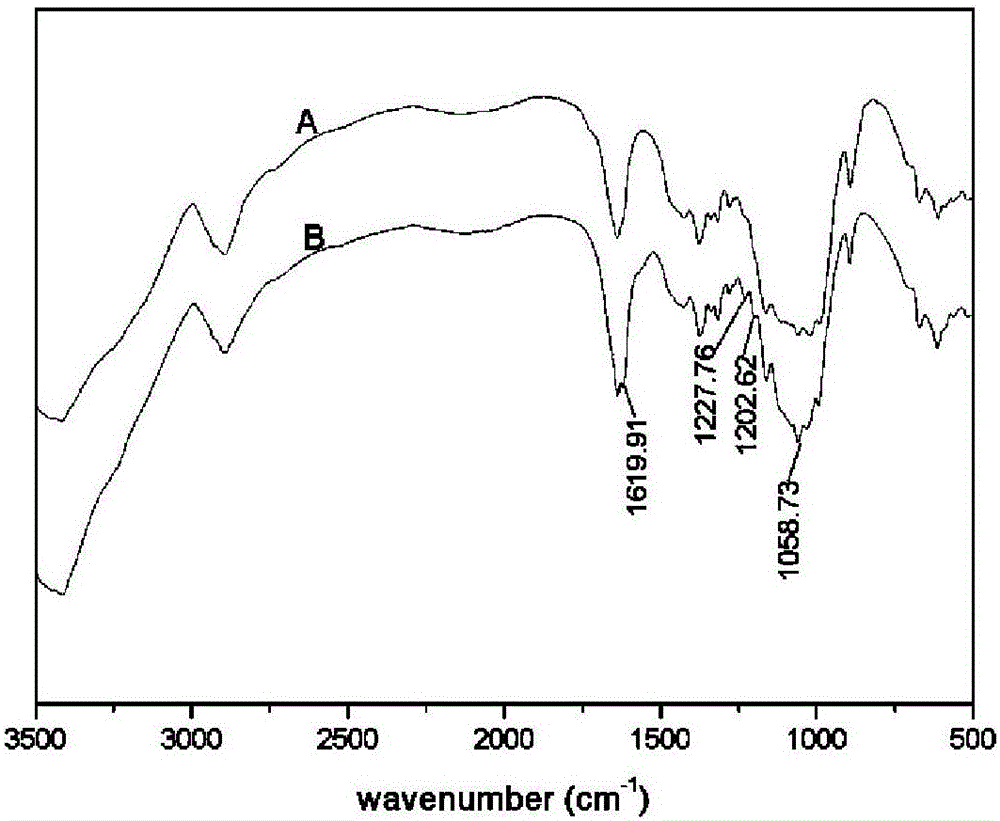

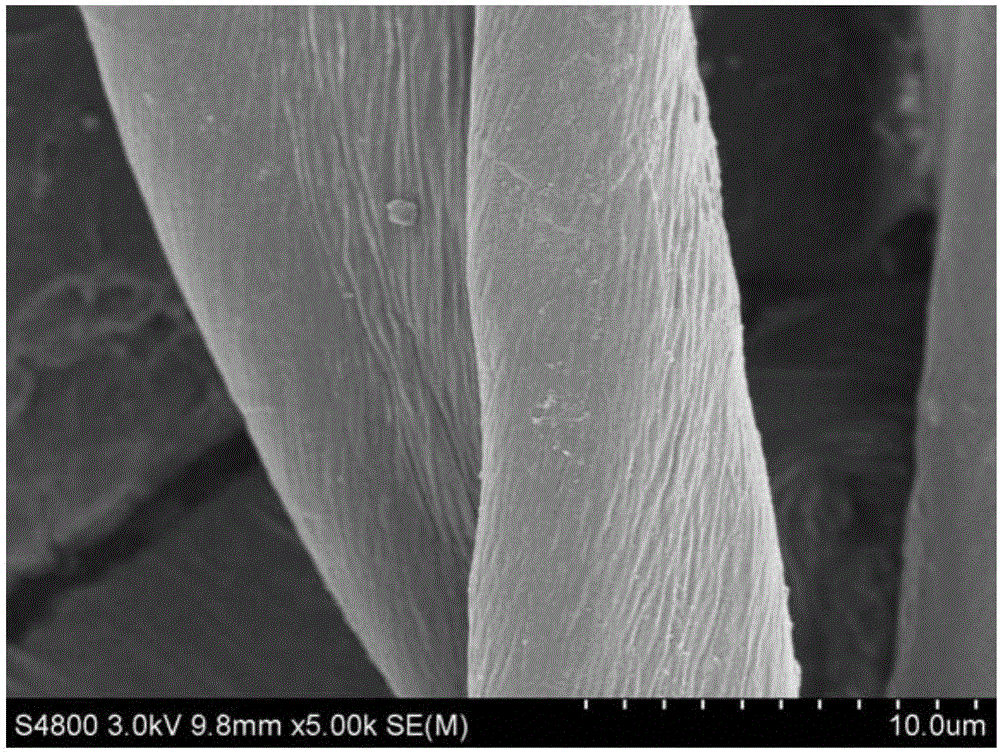

[0030] Weigh 10g of cotton fiber, put it in 500ml of 2% sodium hydroxide solution, boil it for 90min, take it out after cooling and squeeze it dry, then place it in 300ml of 18% sodium hydroxide solution, and let it stand at 18°C. Place and treat for 120 minutes, take it out for washing, and dry to obtain alkalized cotton fibers. Weigh 5 g of alkalized cotton fibers, place them in 150 ml of 2% sodium periodate solution, shake and react in the dark at 70°C for 60 minutes, take them out, wash them, and dry them to obtain selectively oxidized cotton fibers. Add 1g of oxidized cotton fiber to a three-necked flask filled with 30mL of distilled water, mechanically stir evenly, and heat up to 70°C; another 2.5ml of glutaraldehyde mixed with 20mL of distilled water is added dropwise to the solution where the oxidized cotton fiber is located, and the heat preservation reaction is 0.5 h. Then, 10 ml of polyamino hyperbranched polymer aqueous solution with a mass concentration of 10% wa...

Embodiment 2

[0032]Weigh 10g of cotton fiber, put it in 500ml of 2% sodium hydroxide solution, boil it for 90min, take it out after cooling and squeeze it dry, then place it in 300ml of 18% sodium hydroxide solution, and let it stand at 18°C. Place and treat for 120 minutes, take it out for washing, and dry to obtain alkalized cotton fibers. Weigh 5 g of alkalized cotton fibers, place them in 150 ml of 2% sodium periodate solution, shake and react in the dark at 70°C for 60 minutes, take them out, wash them, and dry them to obtain selectively oxidized cotton fibers. Add 1g of oxidized cotton fiber to a three-necked flask filled with 30mL of distilled water, mechanically stir evenly, and heat up to 70°C; another 2.5ml of glutaraldehyde mixed with 20mL of distilled water is added dropwise to the solution where the oxidized cotton fiber is located, and the heat preservation reaction is 0.5 h. Then, 4ml of tetraethylenepentamine solution was added dropwise, and reacted at 70° C. for 240 minut...

Embodiment 3

[0034] Weigh 10g of cotton fiber, put it in 500ml of 2% sodium hydroxide solution, boil it for 90min, take it out after cooling and squeeze it dry, then place it in 300ml of 18% sodium hydroxide solution, and let it stand at 18°C. Place and treat for 120 minutes, take it out for washing, and dry to obtain alkalized cotton fibers. Weigh 5 g of alkalized cotton fibers, place them in 150 ml of 2% sodium periodate solution, shake and react in the dark at 70°C for 60 minutes, take them out, wash them, and dry them to obtain selectively oxidized cotton fibers. Add 1g of oxidized cotton fiber to a three-necked flask filled with 30mL of distilled water, mechanically stir evenly, and heat up to 70°C; another 2.5ml of glutaraldehyde mixed with 20mL of distilled water is added dropwise to the solution where the oxidized cotton fiber is located, and the heat preservation reaction is 0.5 h. Then, 4ml of triethylenetetramine solution was added dropwise, and reacted at 70° C. for 240 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com