Preparation method of biocompatible silk fibroin film for flexible magnetoelectric device substrate

A technology of biocompatible and magnetoelectric devices, which is applied in the field of preparation of biocompatible silk fibroin membranes, can solve the problems of inability to achieve biocompatibility, inability to biodegrade secondary recovery, etc., and achieve great production flexibility and preparation process Simple, fast and low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

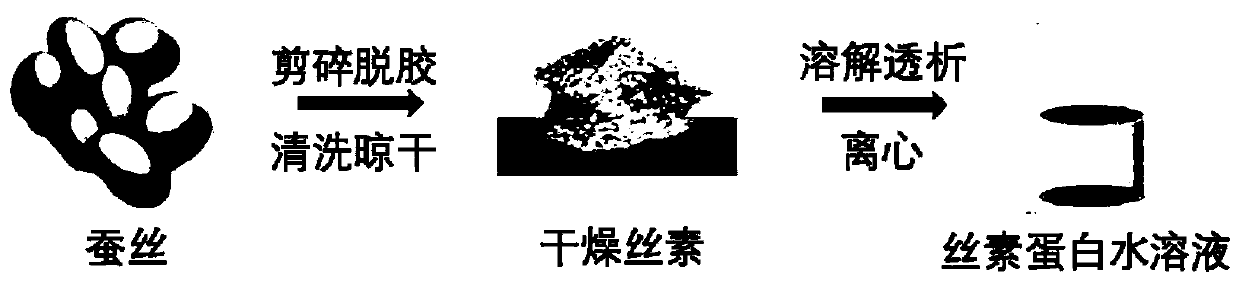

[0027] A method for preparing a biocompatible silk film for a substrate of a flexible magnetoelectric device, comprising the following steps:

[0028] Step 1, using natural silk as a raw material, obtain a pure silk fibroin aqueous solution by cutting, degumming, cleaning, dissolving, dialysis, and centrifugation;

[0029] Step 2, using pure silk fibroin aqueous solution as the biocompatible substrate material for making flexible magnetoelectric devices, and the concentration of silk fibroin is not lower than 5% and not higher than 15%;

[0030] Step 3, cleaning the rigid substrate, the rigid substrate includes a polymethyl methacrylate substrate, a polystyrene substrate or a mica substrate;

[0031] Step 4, coating the silk fibroin aqueous solution on the clean rigid substrate by means of spin coating, drop coating, spray coating, inkjet printing or laser printing;

[0032] Step 5, the solution-coated rigid substrate is naturally air-dried, convectively air-dried or dried; ...

Embodiment 1

[0045] 1) Use a 2L beaker to fill ultrapure water, after boiling

[0046] Add 8g of anhydrous sodium carbonate, weigh 10g of dry silk and add, cook for 20min, stir gently to remove the sericin on the silk. Then rinse with 2L of ultrapure water for 20 minutes, change the water for three times, squeeze out the water, and spread it out on aluminum foil to dry.

[0047] 2) After the silk fibroin is dried, weigh 6g of silk fibroin, corresponding to 20g of lithium bromide, and dissolve it in 25ml solution at a constant volume. Stuff the silk fibroin in the smallest possible beaker and slowly pour the lithium bromide solution into it. Dissolve in an oven at 60°C for 4 hours.

[0048]3) Take two dialysis boxes, soak them in ultrapure water for 20 minutes, insert two needles into the two corners of one side, inject 12ml silk fibroin solution through one needle, and expel the air through the other needle, and finally pull out the needle. Use a sleeve holder to float it in 2L of ultra...

Embodiment 2

[0055] 1) Use a 2L beaker to fill with ultra-pure water, add 8g of anhydrous sodium carbonate after boiling, weigh 10g of dry silk and add, boil for 20min, stir gently to remove sericin on the silk. Then rinse with 2L of ultrapure water for 20 minutes, change the water for three times, squeeze out the water, and spread it out on aluminum foil to dry.

[0056] 2) After the silk fibroin is dried, weigh 6g of silk fibroin, corresponding to 20g of lithium bromide, and dissolve it in 25ml solution at a constant volume. Stuff the silk fibroin in the smallest possible beaker and slowly pour the lithium bromide solution into it. Place in an oven at 60°C to dissolve for 4 hours.

[0057] 3) Take two dialysis boxes, soak them in ultrapure water for 20 minutes, insert two needles into the two corners of one side, inject 12ml silk fibroin solution through one needle, and expel the air through the other needle, and finally pull out the needle. Use a sleeve holder to float it in 2L of ult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com