Overlapped prefabricated reinforced concrete structural system and construction method thereof

A reinforced concrete and concrete technology, which is applied to truss structures, structural elements, and long-strip structural members for load-bearing, etc., can solve the problems of poor fire resistance, long construction time, and poor seismic performance of steel structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

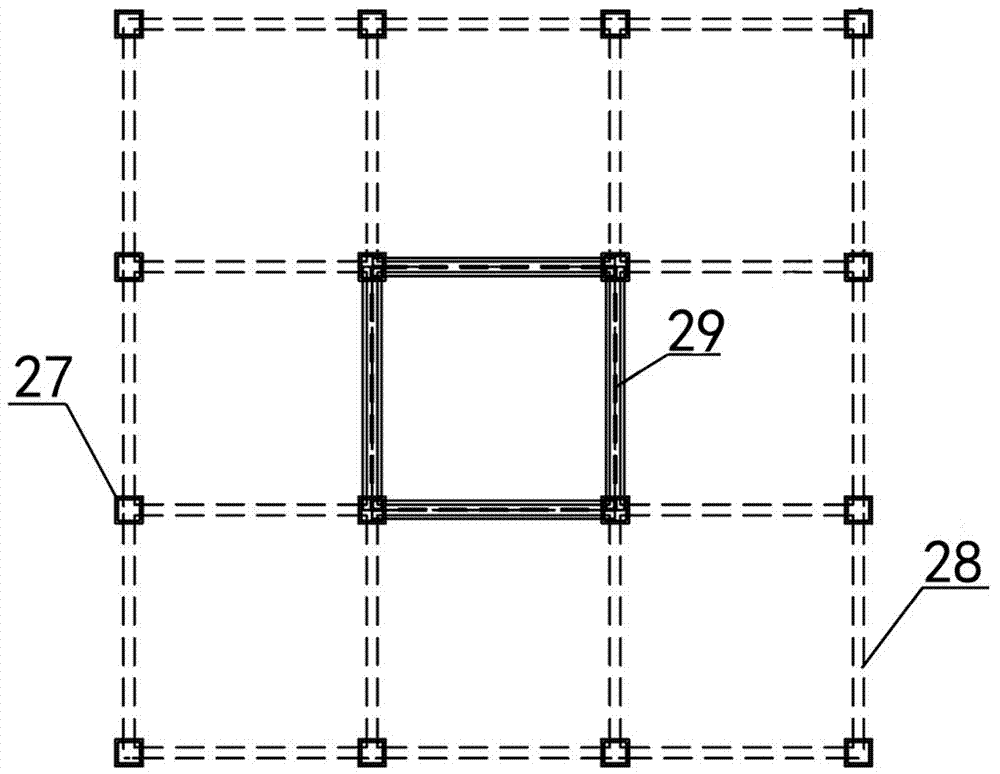

[0112] Embodiment one sees figure 1 As shown, a laminated prefabricated reinforced concrete structure system includes a frame structure system composed of foundation 24, structural columns 27, structural beams 28 and floor slabs 26 connected.

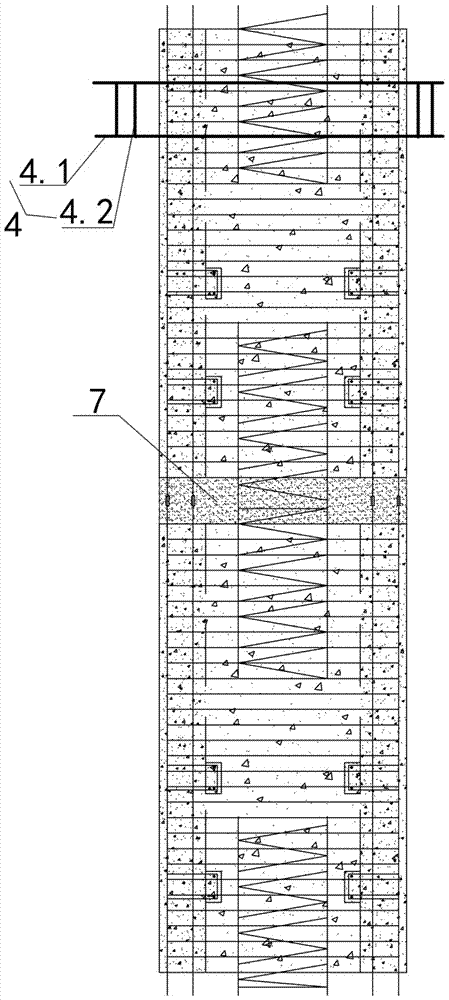

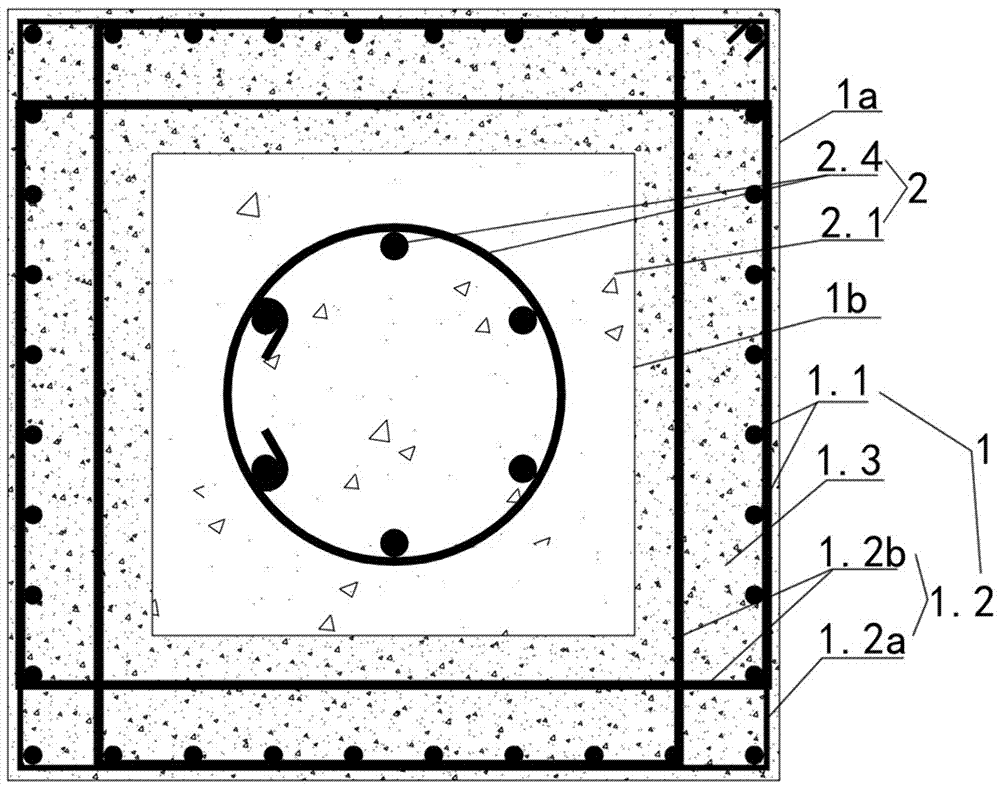

[0113] see Figure 2-3 As shown, at least one of the structural columns is a reinforced concrete composite pipe column, and the reinforced concrete composite pipe column includes at least two column sections connected up and down, and the end of the column section connected to the structural beam is a connection node area , each column section includes an external prefabricated pipe string 1 and a cast-in-place core string 2 that uses the prefabricated pipe string 1 as an outer mold and is poured inside the prefabricated pipe string.

[0114] The prefabricated pipe column 1 is a reinforced concrete column, including a pipe column reinforcement cage and a pipe column concrete 1.3, the pipe column reinforcement cage is wrapped in the pip...

Embodiment 2

[0123] Embodiment two see Figure 7-8 As shown, the difference from the first embodiment is that the nodal beam reinforcement cage 4 is not provided, but the prefabricated pipe column is pre-embedded with an embedded part 5 connected by mutually perpendicular anchor legs 5.2 and anchor plates 5.1 , the anchor legs are pre-embedded in the pipe column concrete, and the embedded parts 5 are fixedly connected with the ends of the structural beams.

[0124] see Figure 9 As shown, at least one of the structural beams is a prefabricated composite reinforced concrete beam 9, and the prefabricated composite reinforced concrete beam 9 includes a prefabricated reinforced concrete channel beam 91 and a cast-in-place core poured inside the reinforced concrete channel beam Beam 92 , the end of the prefabricated laminated reinforced concrete beam 9 is connected with an end steel beam 10 , and the end connecting steel beam 10 is fixedly connected with the embedded part 5 .

Embodiment 3

[0125] Embodiment 3 is shown in the figure, different from Embodiment 2, see Figure 10 As shown, the cross-sectional shape of the outer wall 1a of the pipe string is circular, and the cross-sectional shape of the inner wall 1b of the pipe string is circular. Therefore, the outer wall stirrup 1.2a is circular, and the inner wall stirrup 1.2b is also designed to be circular, and the inner wall stirrup 1.2b is bound together with the longitudinal bar 1.1 of the pipe column.

[0126] see Figure 11-13 As shown, at least one of the structural beams is a prefabricated variable stiffness hybrid composite beam 8, and the prefabricated variable stiffness hybrid composite beam 8 includes a steel skeleton 81 and reinforced concrete blocks arranged on both sides of the web of the steel skeleton 81 82;

[0127] The steel skeleton includes an upper flange plate, a lower flange plate and a web located in the middle of the flange plate and connected between the upper and lower flange plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com