2,5-furandimethanol diester plasticizer and preparation method thereof

A technology of furan dimethanol and plasticizer, which is applied in the direction of organic chemistry to achieve the effect of reducing dependence, good compatibility and solving environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

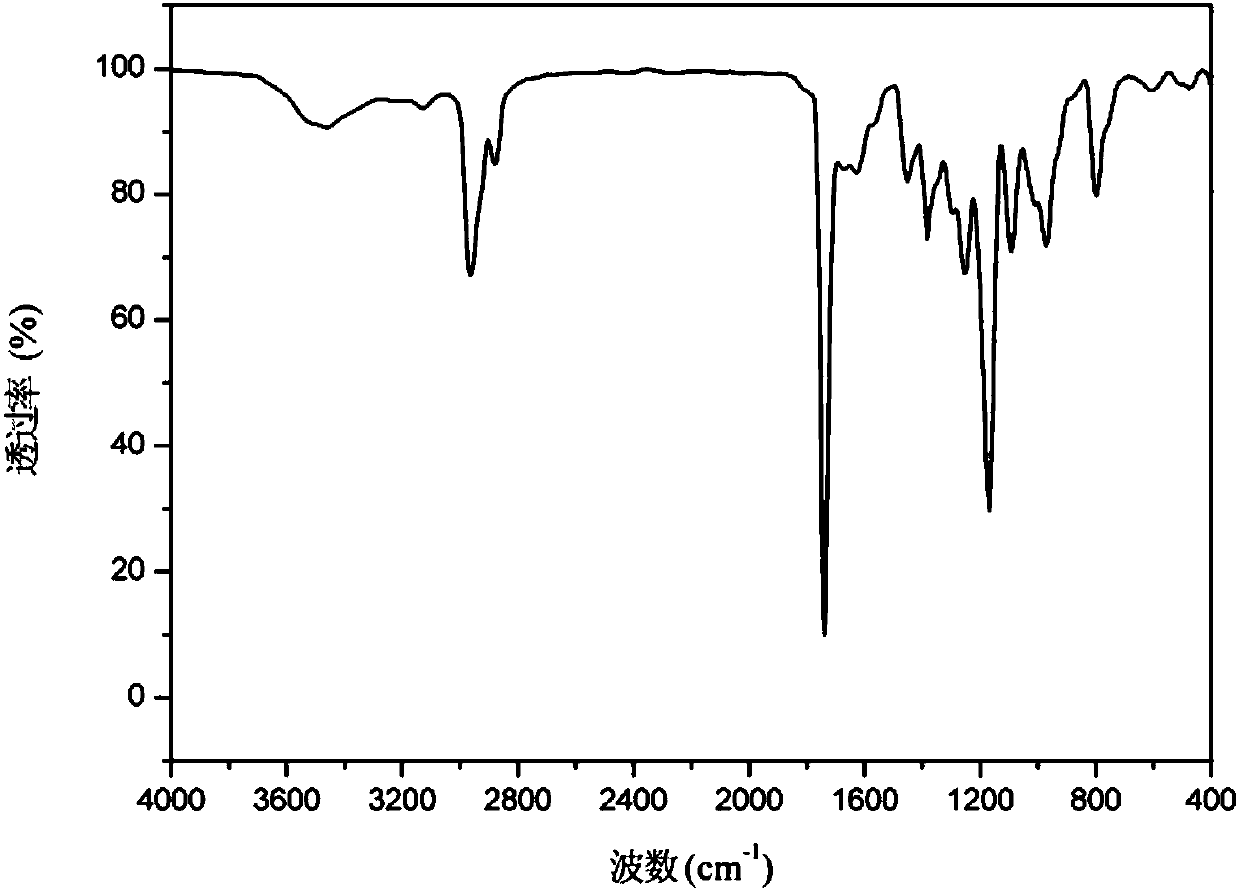

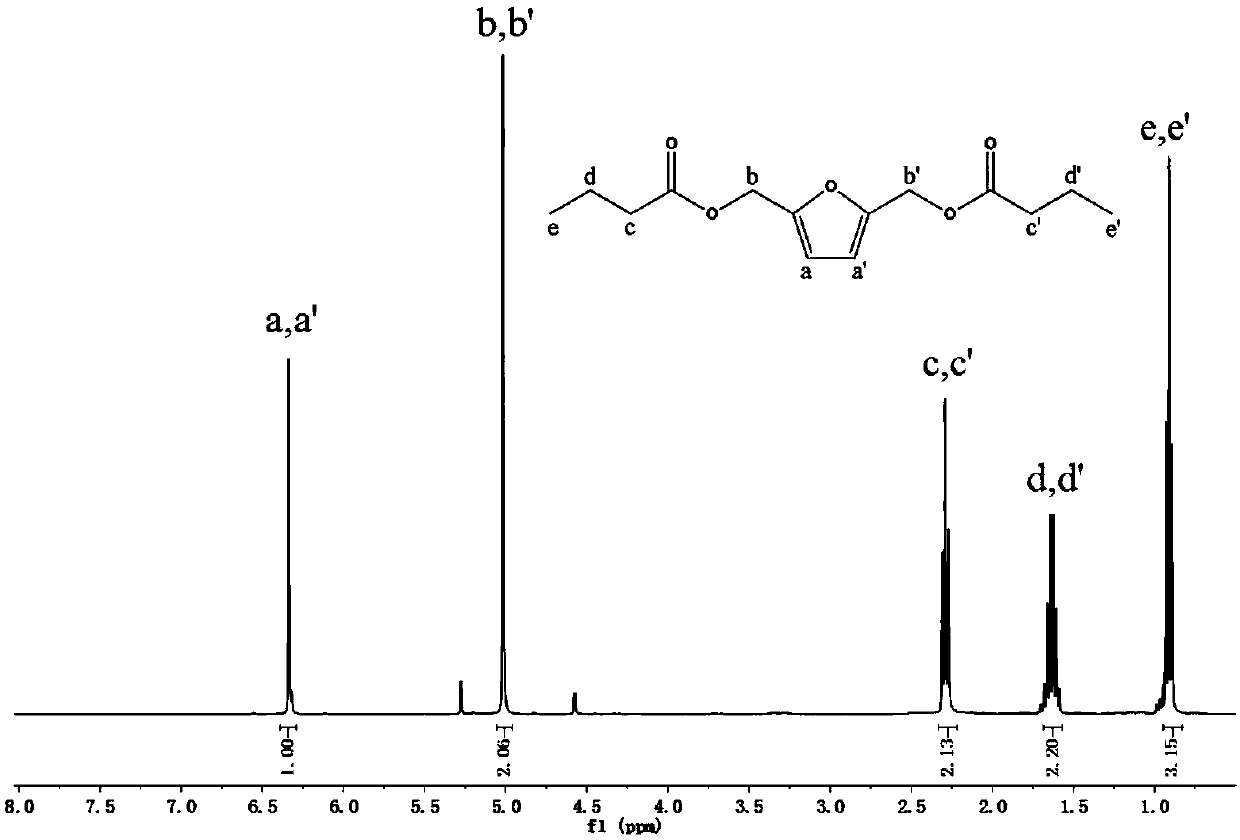

[0033] Add 6.406g (0.05mol) of 2,5-furandimethanol, 11.104g (0.12mol) of n-butyric acid, 0.1g of p-toluenesulfonic acid and 8ml of toluene into a three-neck flask with a condensing reflux device and a water separator. After being heated to the first drop of toluene and starting to reflux, continue to reflux for 4 hours, then carry out vacuum distillation to obtain 2,5-furandimethanol dibutyrate, and its infrared spectrum and nuclear magnetic resonance spectrum are shown in figure 1 and figure 2 .

Embodiment 2

[0035] Add 6.406g (0.05mol) of 2,5-furandimethanol, 14.081g (0.11mol) of n-hexanoic acid, 0.15g of p-toluenesulfonic acid and 10ml of toluene into a three-necked flask with a condensing reflux device and a water separator. After heating until the first drop of toluene starts to reflux, continue to reflux for 5 hours, and then carry out vacuum distillation to obtain 2,5-furandimethanol dihexanoate.

Embodiment 3

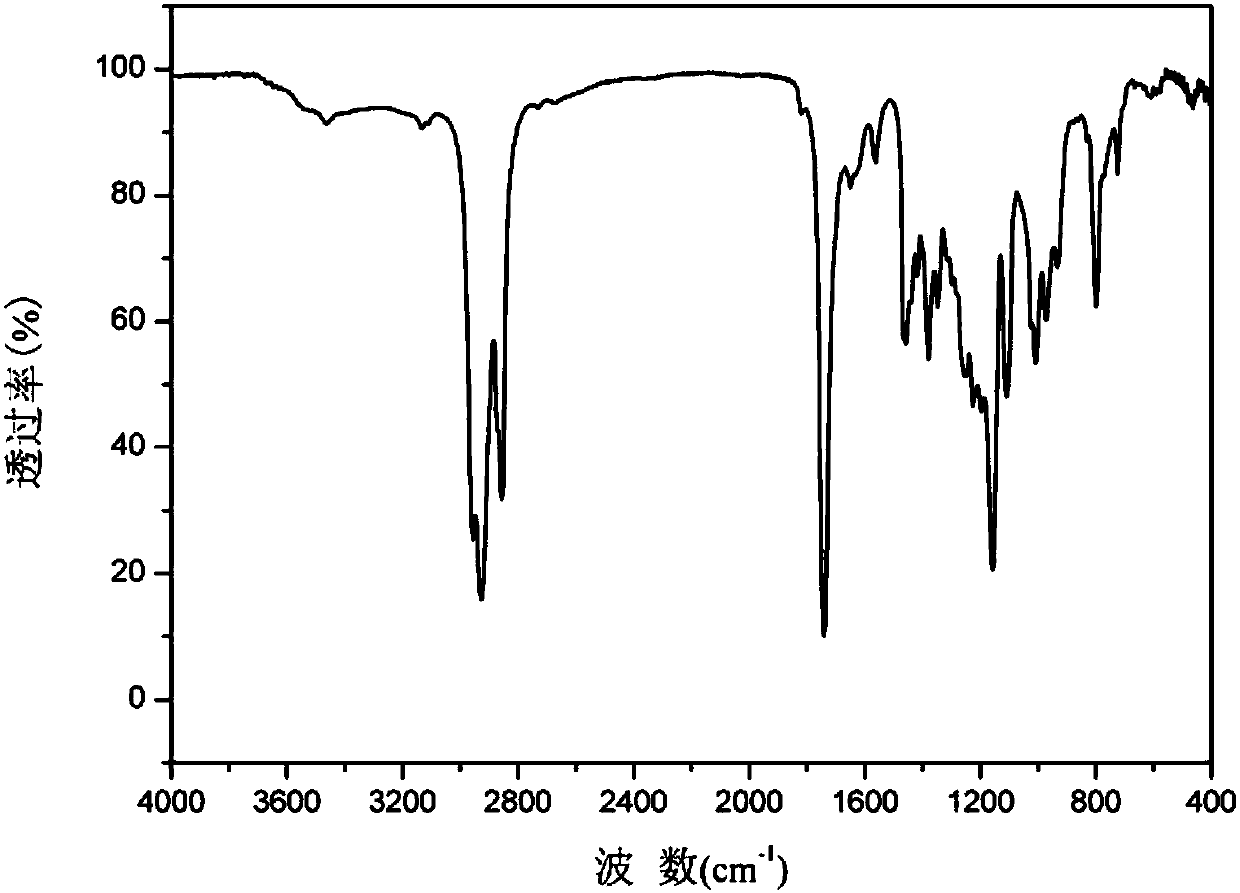

[0037] Add 6.406g (0.05mol) of 2,5-furandimethanol, 20.924g (0.13mol) of n-octanoic acid, 0.15ml of concentrated sulfuric acid and 12ml of toluene into a three-necked flask with a condensing reflux device and a water separator. After being heated to the first drop of toluene and starting to reflux, continue to reflux for 6 hours, then carry out vacuum distillation to obtain 2,5-furandimethanol dioctanoate, its infrared spectrum and nuclear magnetic resonance spectrum are shown in image 3 and Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com