Ethanol conversion method

An ethanol and reactor technology, applied in the field of ionic synthesis chemistry, to achieve the effect of high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

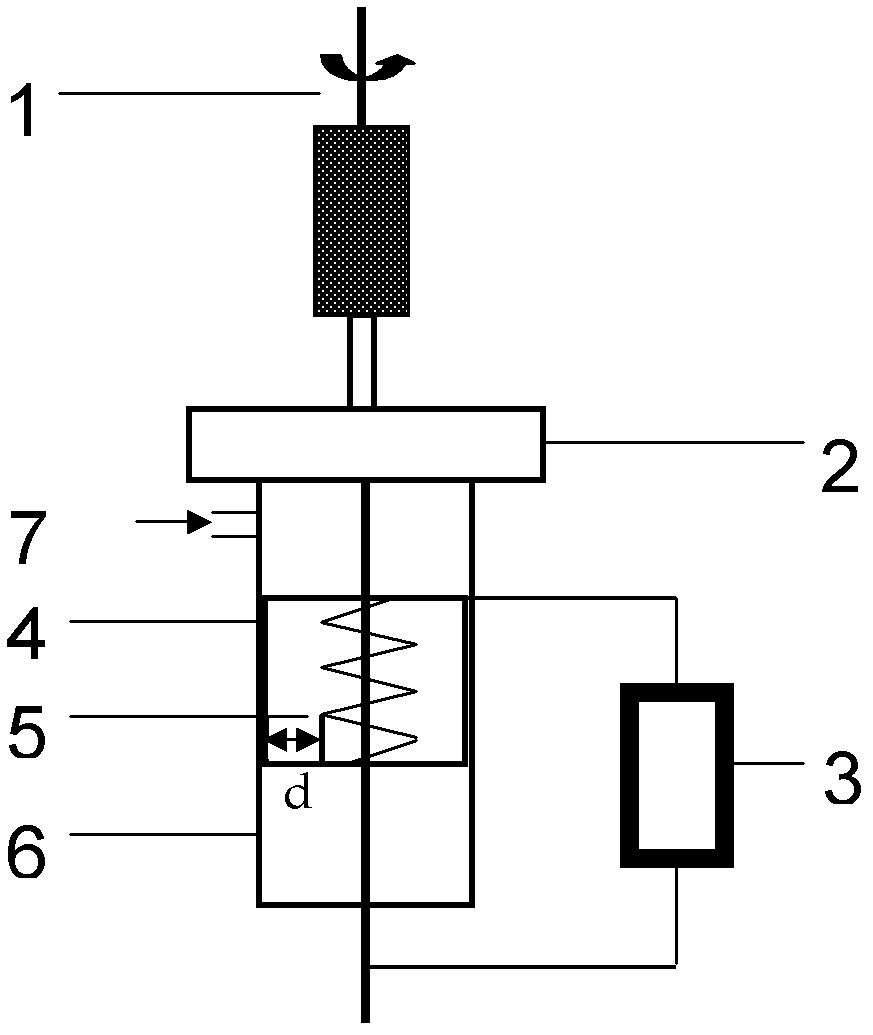

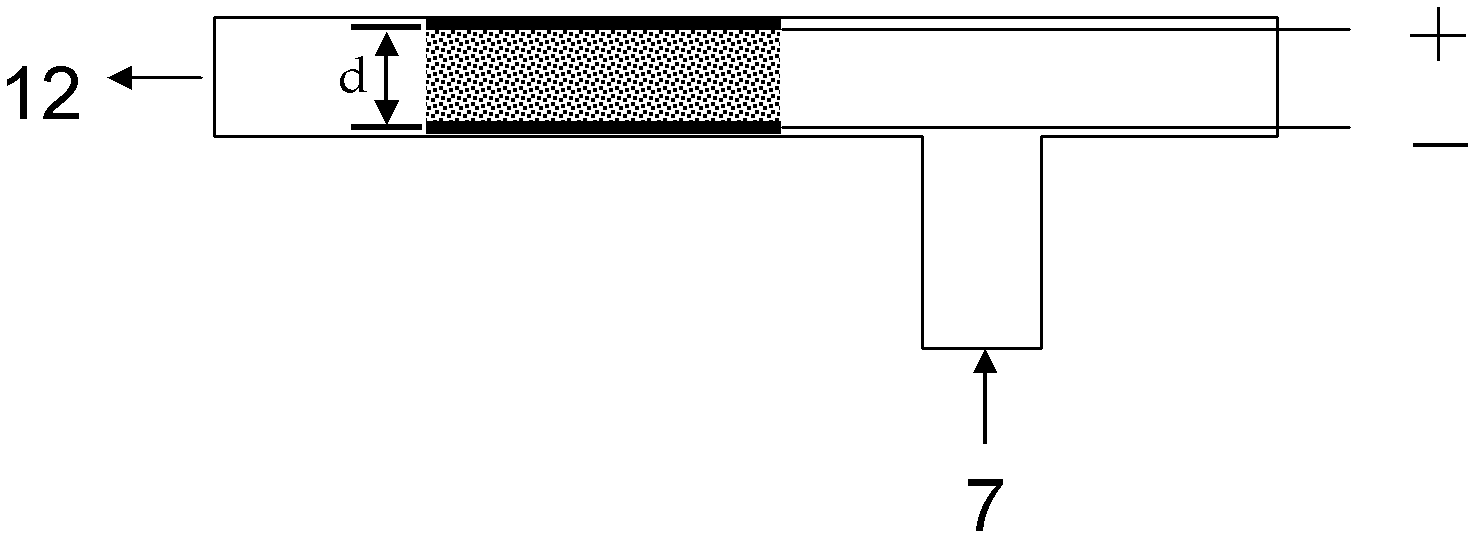

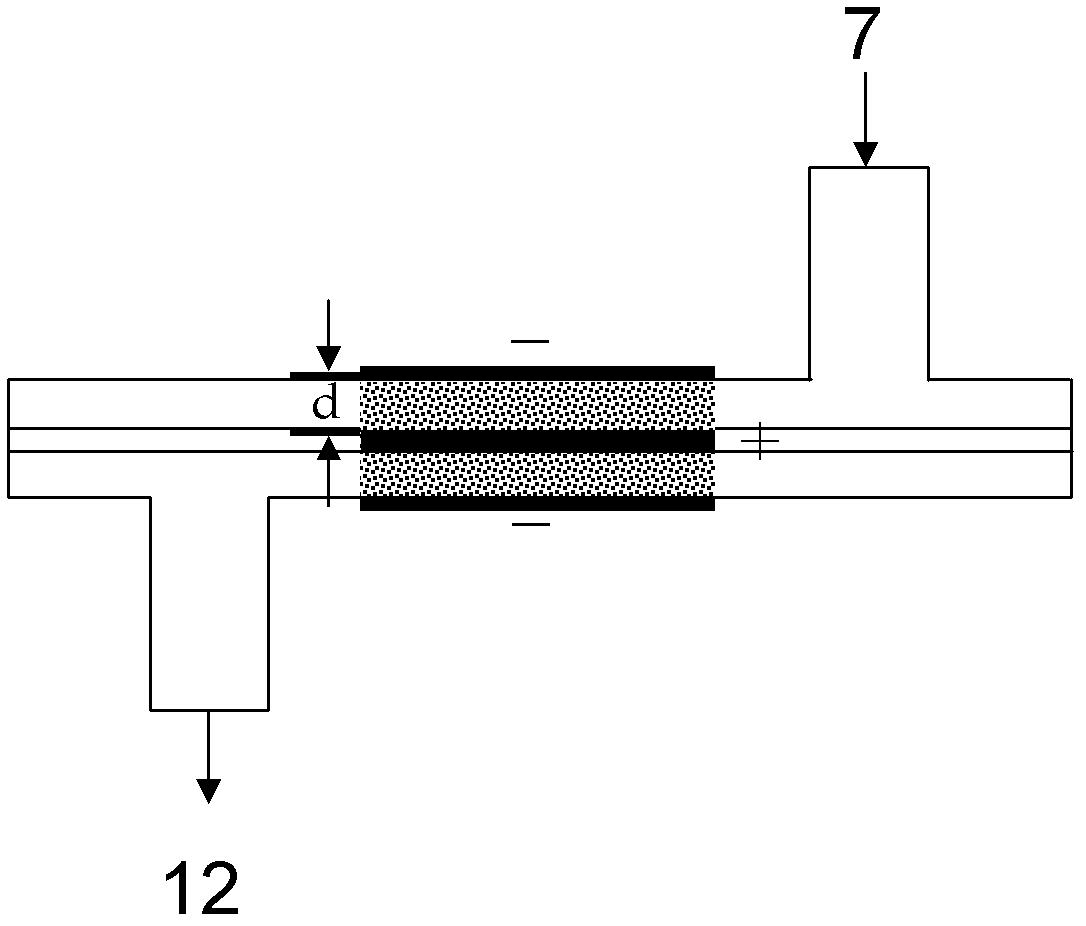

[0112] Example 1: Single dielectric barrier discharge --- wire barrel reactor

[0113] Under the pressure of 0.11MPa, He and gaseous ethanol are passed into the discharge reactor at a molar ratio of 5:1 (the flow rate of He is 25ml / min, and the flow rate of ethanol is 5ml / min). Block discharge. Use a hard glass tube with an outer diameter of 9 mm and an inner diameter of 7 mm to make a cylindrical reactor (also used as a barrier medium), the central electrode is an iron wire with a diameter of 3 mm, and the ground electrode is a cylindrical aluminum foil tube with a wall thickness of 1 mm (close to the glass tube. outer wall), the pole spacing is 3mm, and the effective discharge length of the reactor is 120mm.

[0114] The discharge parameters of the reactor are: voltage 12.5kV, current 0.36A, frequency 14.5kHz; other reaction conditions of the reactor are: the residence time of the reactant in the discharge area is 8s, and the discharge temperature is 230°C. Then the reacti...

Embodiment 2

[0115] Example 2: Double Dielectric Barrier Discharge --- Wire Barrel Reactor

[0116] Under the pressure of 0.12MPa, the N 2 and gaseous ethanol in a molar ratio of 6:1 (wherein N 2 The flow rate is 36ml / min, and the ethanol flow rate is 6ml / min) into the discharge reactor, and after the airflow is stable, the plasma power supply is switched on for dielectric barrier discharge. A cylindrical reactor is made of double-layer polytetrafluoroethylene tube (also used as a barrier medium), in which the outer diameter of the outer tube is 11mm, the inner diameter is 8mm, the outer diameter of the inner tube is 4mm, the inner diameter is 2mm, the center electrode is a copper wire with a diameter of 2mm, grounded Cylindrical copper mesh (180 mesh) with a wall thickness of 1 mm and close to the outer wall of the polytetrafluoroethylene tube, the pole spacing is 4.5 mm, and the effective discharge length of the reactor is 180 mm.

[0117] The discharge parameters of the reactor are: v...

Embodiment 3

[0118] Example 3: Single dielectric barrier discharge --- tube-sheet reactor

[0119] Under the pressure of 0.05MPa, CO and gaseous ethanol are passed into the discharge reactor at a molar ratio of 8:1 (the flow rate of CO is 48ml / min, and the flow rate of ethanol is 6ml / min). Block discharge. The reactor is made of a hard glass tube with an outer diameter of 9mm and an inner diameter of 7mm. It adopts a tube-sheet electrode structure. The high-voltage pole is an iron tube with an outer diameter of 3mm and an inner diameter of 2mm. The ground pole is a circular tungsten plate with a radius of 3.5mm. mm of single-layer mica with a pole spacing of 4mm.

[0120] The discharge parameters of the reactor are: voltage 15.8kV, current 0.55A, frequency 10.5kHz; other reaction conditions of the reactor are: the residence time of reactants in the discharge area is 0.58s, and the discharge temperature is 460°C. Then the reaction result is: ethanol conversion rate 13%, acetaldehyde selec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com