Power generation technique based on pyrolyzation and gasification of household refuse and incineration of fuel gas

A technology for pyrolysis gasification and domestic waste, applied in combustion methods, combustion types, incinerators, etc., can solve problems such as waste of exhaust heat energy, secondary pollution, affecting soil quality, etc., to solve waste pollution, improve power generation efficiency, reduce Effects of Dioxins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

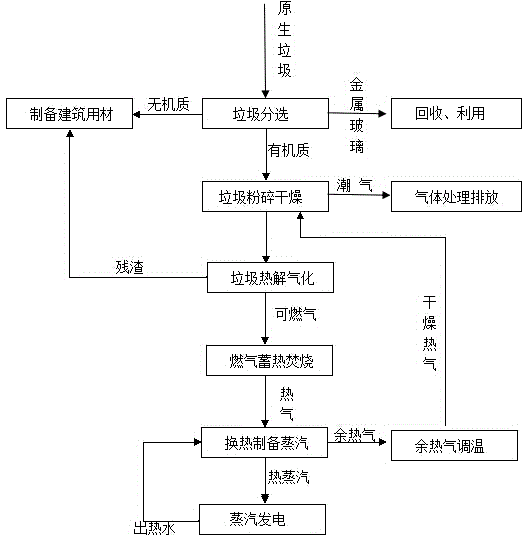

[0029] Example: The domestic waste pyrolysis gasification gas incineration power generation process according to the present invention follows the following steps: 1) Sorting out the inorganic substances such as metal, glass, stones and the like in the original domestic waste. The sorting process can be manual or machine selection. Sorting is based on (inorganic substances) that can be clearly seen by the human eye. Using a number of workers can improve efficiency, and the sorted inorganic substances such as metal and glass can be recycled and reused. : Stones, bricks, etc. can be used to prepare building materials and retain organic matter (organic components) in domestic waste; 2) Put the remaining organic domestic waste after sorting and removing inorganic matter into a crusher for crushing, and use an ordinary garbage crusher Just crush it; 3) Put the crushed organic domestic waste into the drying equipment for drying treatment, and the odor or moisture generated during t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com