Cleaning production process of glycine

A technology of clean production and glycine, which is applied in the field of clean production technology of glycine, can solve the problems of increased production cost, waste of raw materials, poor product quality, etc., and achieve the effect of saving production cost, no three waste pollution, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: a kind of clean production process of glycine, it uses the mixed solution of glycine and ammonium chloride produced on the basis of chloroacetic acid ammonolysis method as raw material, adopts the method for electrodialysis to separate glycine and ammonium chloride, and the specific process steps are as follows :

[0016] 1) The mixed solution of glycine and ammonium chloride produced by the ammonolysis method of chloroacetic acid is subjected to solid-liquid separation after cooling and crystallization, and the separated solution is diluted to control the mass percentage of glycine in the solution to 5-20%, ammonium chloride The mass percentage is 8-18%;

[0017] 2) The above-mentioned diluted solution enters the electrodialyzer for electrodialysis treatment, and separates glycine and ammonium chloride. The pH is not adjusted in the early stage of separation. When the mass percentage of ammonium chloride in the light chamber is less than 5%, the pH of the...

Embodiment 2

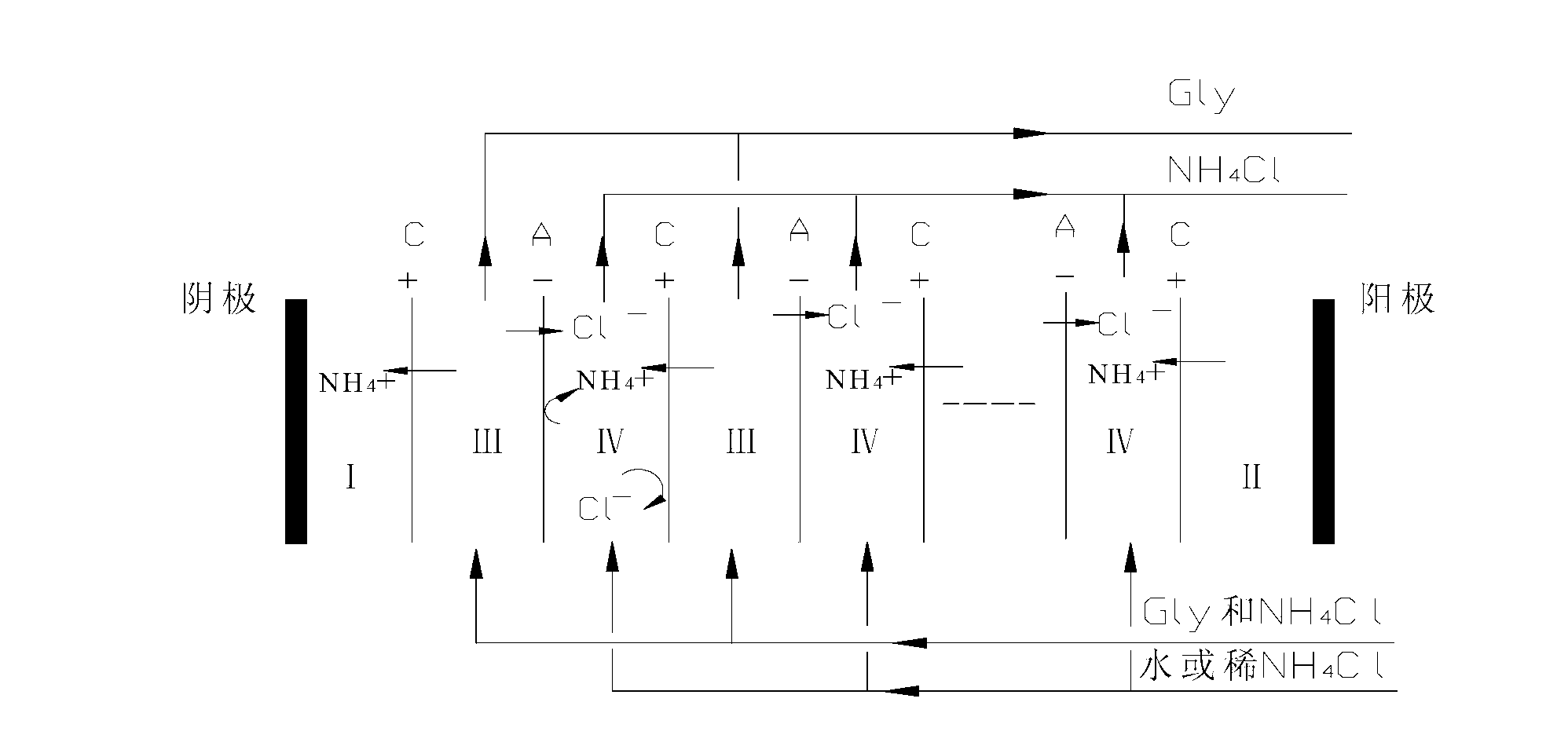

[0021] Embodiment 2: refer to figure 1 . Both sides of the electrodialyzer are respectively provided with a cathode chamber I with a built-in cathode and an anode chamber II with a built-in anode, and a membrane pair is arranged between the cathode chamber I and the anode chamber II, and the membrane pair is composed of several anion exchange membranes A and a number of cation exchange membranes C, the anion exchange membranes A and cation exchange membranes C are alternately arranged between the cathode chamber I and the anode chamber II, and the cation exchange membrane C is used on the side adjacent to the cathode chamber I and the anode chamber II, close to The compartment formed by the cation exchange membrane C of the cathode compartment I and the adjacent anion exchange membrane A is the dilute compartment III, and the compartment adjacent to the dilute compartment III is the concentrated compartment IV, and the dilute compartment III and the concentrated compartment IV...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com