Diaphragm attaching method and diaphragm attaching device

A film and attachment technology, applied in lamination devices, chemical instruments and methods, layered products, etc., can solve the problems of easy generation of air bubbles, difficult to attach polarizers and substrates with high precision, etc., to improve the alignment The effect of precision and high-precision attachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

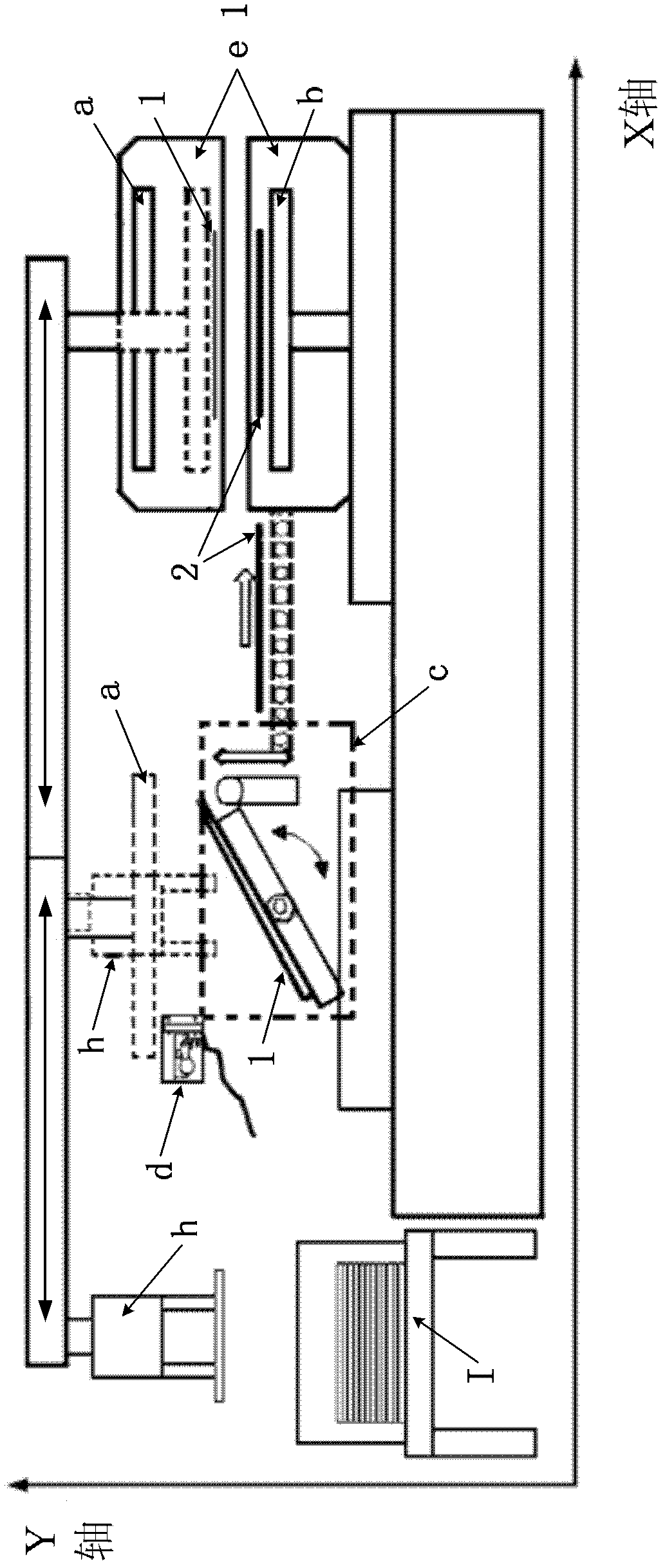

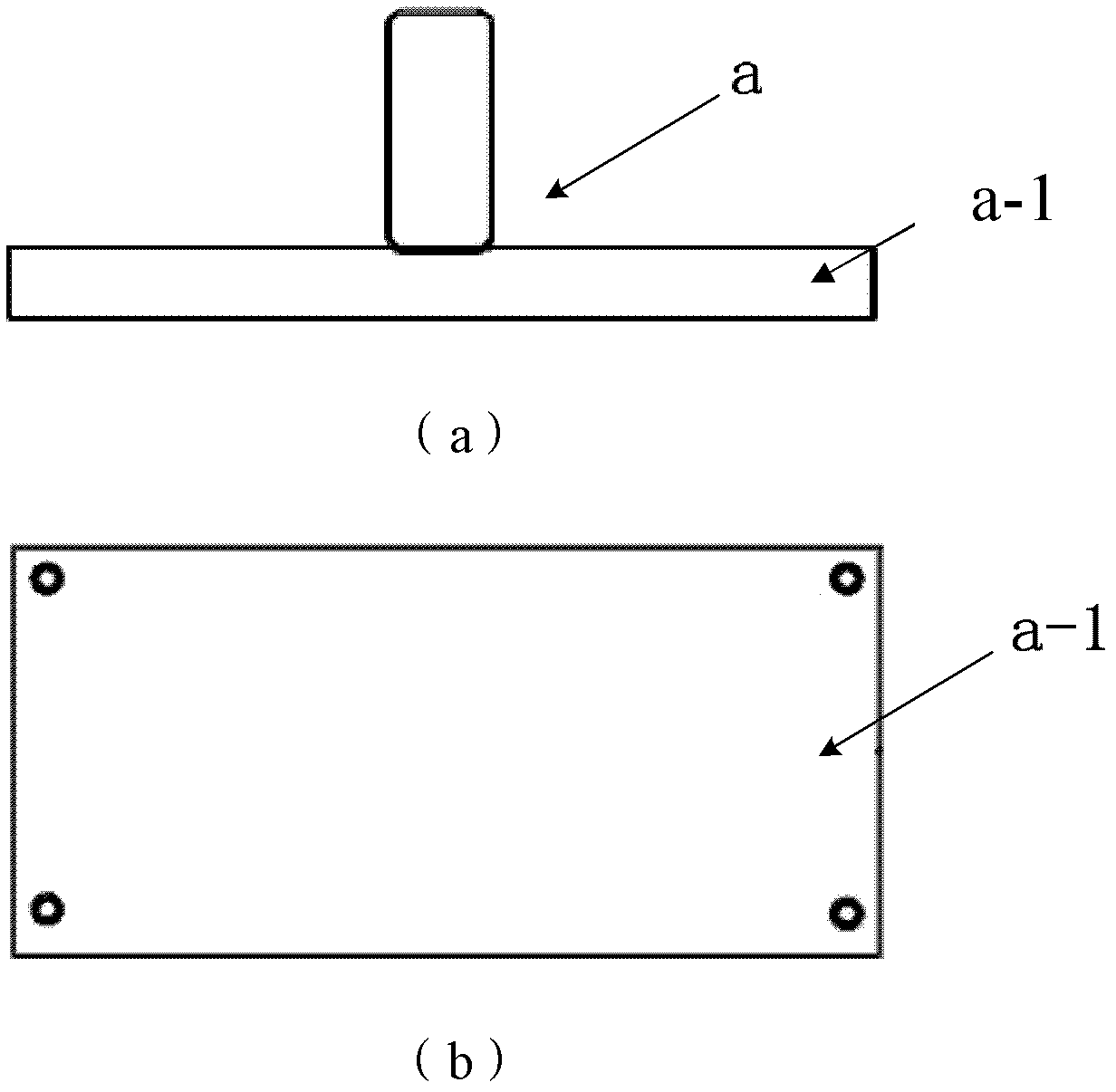

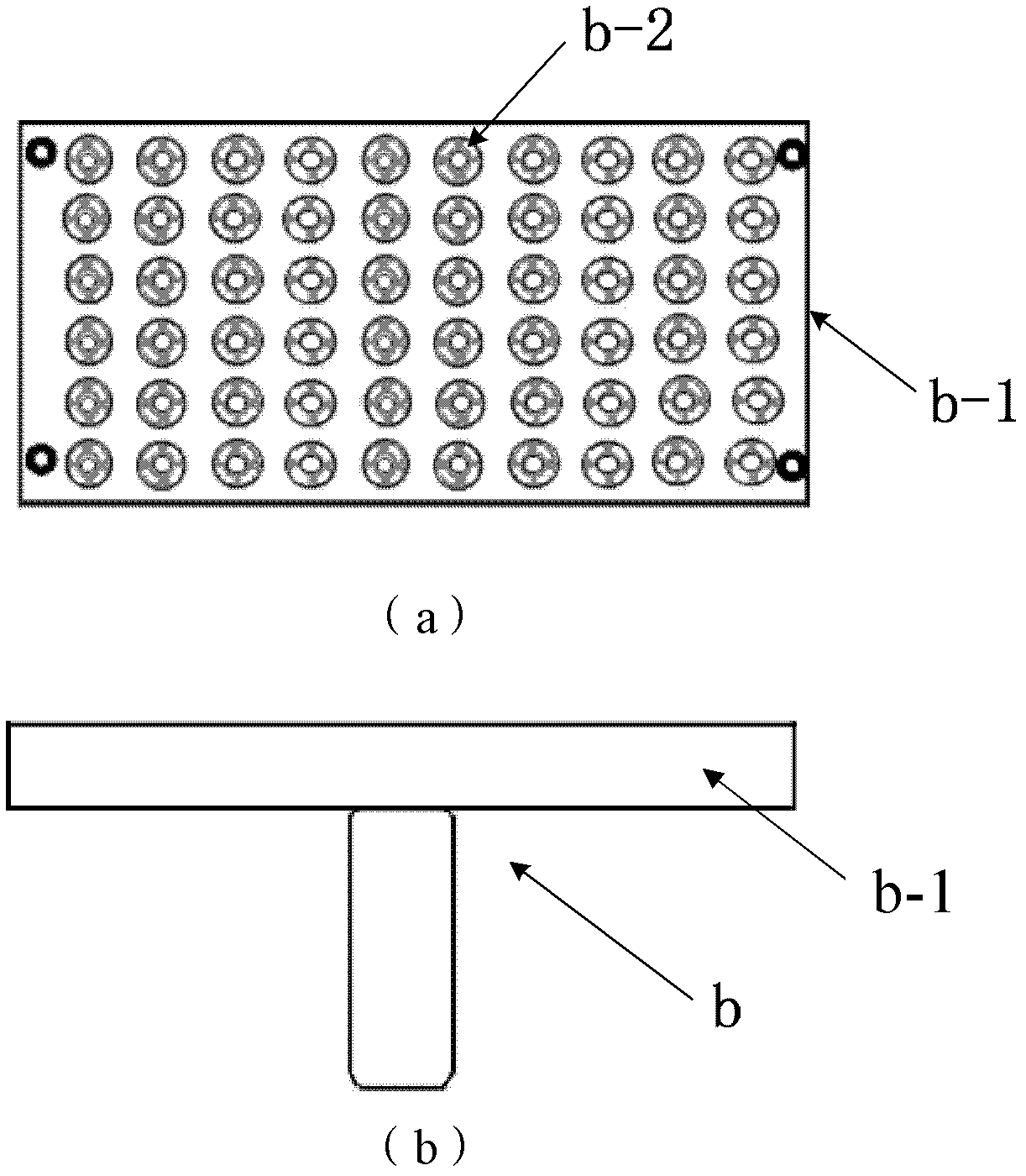

[0056] figure 1 It is a schematic diagram of the overall structure of the film sticking device in this embodiment. Such as figure 1 As shown, the film attaching device includes a film supply mechanism h, a substrate conveying mechanism, a film adsorption unit a, a substrate adsorption unit b, a film flattening unit c, a film protective film peeling unit d, a motion unit, Bit unit, vacuum unit e and control unit (not shown in the figure). Among them, the diaphragm adsorption unit a is used to adsorb the diaphragm 1, the substrate adsorption unit b is used to adsorb the substrate 2, the motion unit is used to drive the diaphragm adsorption unit and the substrate adsorption unit to move, and the control unit is used to control the movement process of the whole device. control.

[0057] Out of right figure 1 Considering the clarity, the image sensor mark capture unit f and the position adjustment unit g are in figure 1 is not shown in , while the vacuum unit e is in figure 1...

Embodiment 2

[0097] The difference between this embodiment and Embodiment 1 is that in this embodiment, in the membrane attachment method, the membrane 1 and the substrate 2 are directly surface-attached instead of surface-attached in a vacuum environment; correspondingly, this The film sticking device in the embodiment also does not have a vacuum unit.

[0098] Other steps and structures in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

[0099] It should be noted that the film in the present invention can be a three-dimensional polarizer or a film made of other flexible materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com