Production method of low carbon steel plate and low carbon steel plate

A low-carbon steel plate and low-carbon steel technology, applied in the field of low-carbon steel plate, can solve the problems of low-carbon steel plate with poor effect and easy to produce horizontal stripes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

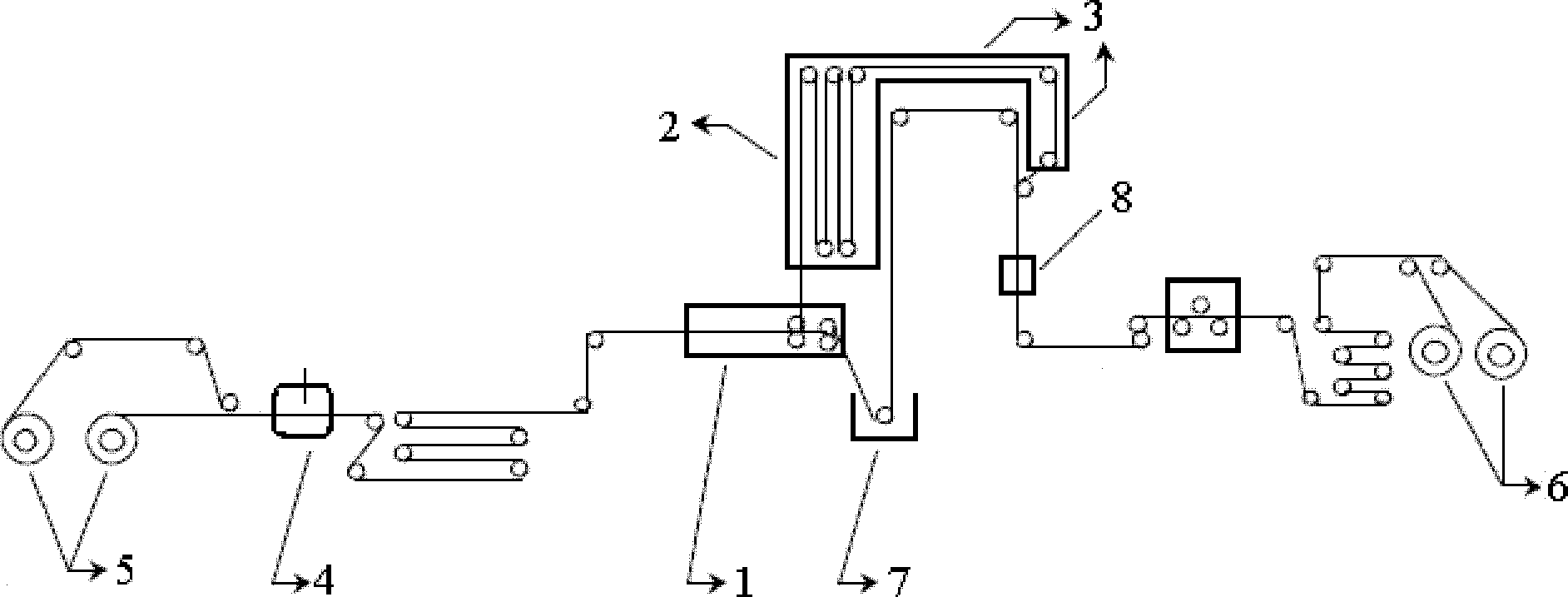

Image

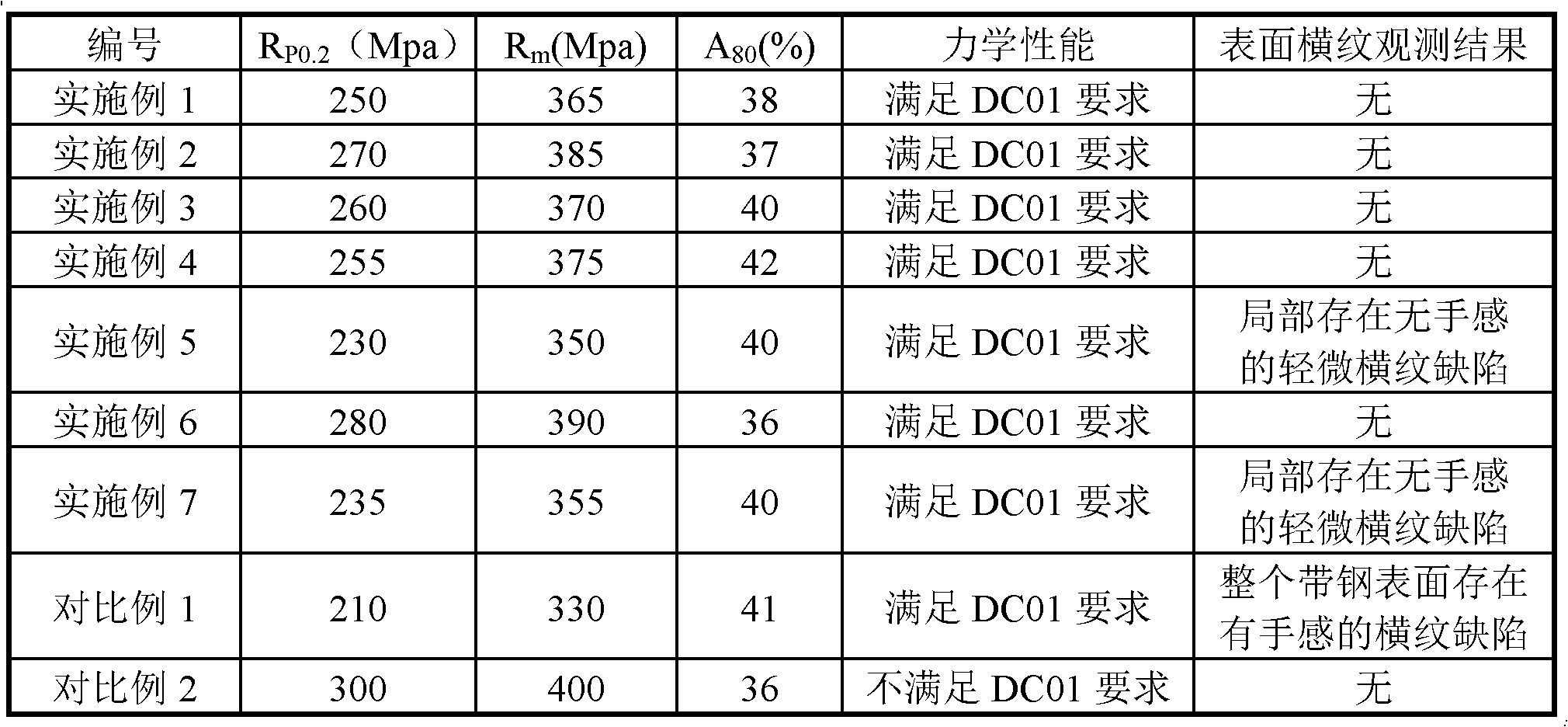

Examples

preparation example Construction

[0016] According to the present invention, the preparation method of the low-carbon steel slab can adopt conventional methods in the art, as long as it is preferred to make the low-carbon steel slab of the present invention, based on the total weight of the low-carbon steel slab, The carbon content is 0.06-0.1% by weight, the silicon content is ≤0.05% by weight, the manganese content is 0.3-0.45% by weight, the phosphorus content is ≤0.025% by weight, the sulfur content is ≤0.025% by weight, and the aluminum content is 0.02-0.07% by weight. Generally speaking, the preparation method of the low-carbon steel slab includes: performing primary smelting of molten iron to obtain molten steel, and tapping the molten steel obtained from the primary smelting into a ladle; performing pre-deoxidation alloying on the molten steel during the tapping process and carburization; after tapping, carry out ladle furnace refining to the molten steel in the ladle, and the ladle furnace refining usu...

Embodiment 1

[0030] This embodiment is used to illustrate the method for producing low carbon steel plate provided by the present invention.

[0031] (1) Formation of cold-rolled sheet:

[0032] The low-carbon steel slab (composition: based on the total weight of the low-carbon steel slab, C: 0.1% by weight, Si: 0.01% by weight, Mn: 0.43% by weight, P: 0.02% by weight, S: 0.015% by weight , Al: 0.05% by weight, the balance is iron) After soaking at 1200°C, rough roll into a 30mm thick intermediate billet with a rough rolling mill, and the final rolling temperature of the rough rolling is 1050°C; then roll a 3.33mm thick billet with a finishing mill For hot-rolled strip steel, the final rolling temperature of finish rolling is 860°C; immediately after finish rolling, it is cooled to 720°C at a rate of 200°C / s, and then cooled to 650°C at a rate of 20°C / s, and enters the coiler coil Take a roll. After the strip is cooled to room temperature (25°C), it is pickled with hydrochloric acid with...

Embodiment 2

[0037] This embodiment is used to illustrate the method for producing low carbon steel plate provided by the present invention.

[0038] (1) Formation of cold-rolled sheet:

[0039] The low-carbon steel slab (composition: based on the total weight of the low-carbon steel slab, C: 0.06% by weight, Si: 0.03% by weight, Mn: 0.31% by weight, P: 0.01% by weight, S: 0.011% by weight , Al: 0.02% by weight, and the balance is iron) After soaking at 1250°C, rough roll into a 32mm thick intermediate billet with a rough rolling mill, and the final rolling temperature of the rough rolling is 1100°C; then roll a 3mm hot billet with a finish rolling mill For strip rolling, the final rolling temperature of finish rolling is 900°C; immediately after finish rolling, it is cooled to 670°C at a rate of 100°C / s, and then cooled to 640°C at a rate of 15°C / s, and then enters the coiler for coiling into rolls. After the strip is cooled to room temperature (25°C), it is pickled with hydrochloric ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com