Blisk flexible grinding and polishing machining process for improving outer surface roughness

A technology of integral blisk and processing technology, which is applied in the direction of grinding workpiece support, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of high surface stress concentration and increased roughness, and achieve improved consistency and reduced Roughness, the effect of avoiding the texture of the knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

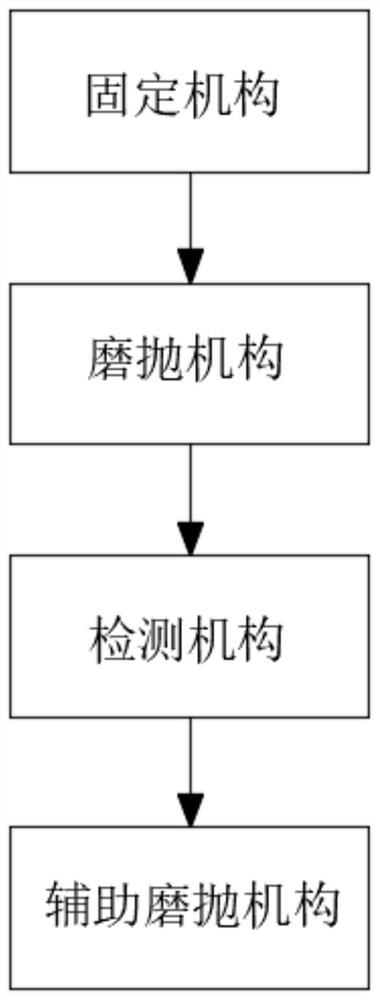

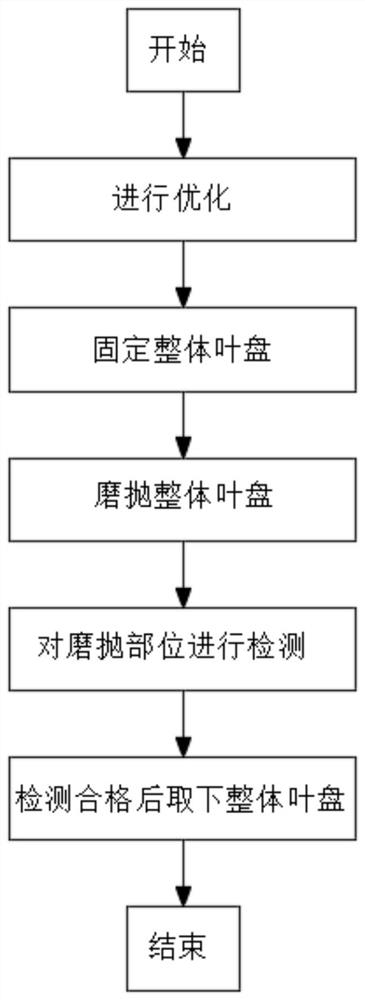

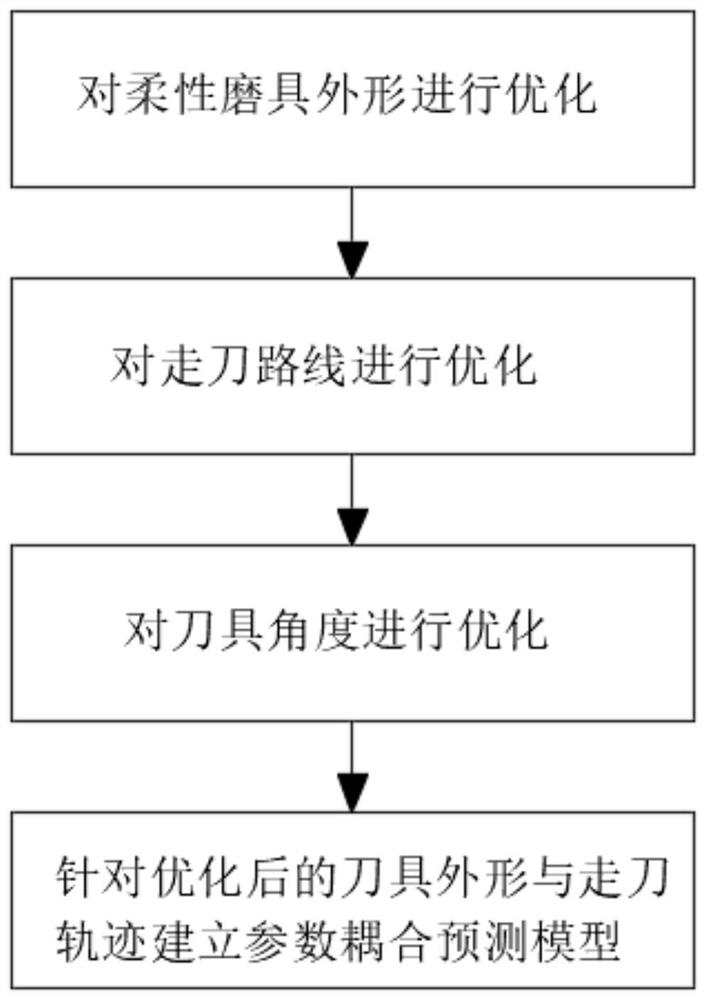

[0042] refer to Figure 1-6 , a flexible grinding and polishing process of an integral blisk for improving the roughness of the outer surface, comprising the following steps:

[0043] S1. Analysis of the flexible grinding and polishing of the overall blisk: In order to avoid the joint texture of the flexible grinding and polishing, the shape of the flexible abrasive is optimized through theoretical calculation and simulation analysis, so that the abrasive is more suitable for the complex freedom of the overall blisk / blade For grinding and polishing of curved surfaces, through calculation and simulation analysis, the deformation of blisks caused by grinding and polishing is studied, and then the cutting route and tool angle are optimized, so that the actual grinding and polishing route and tool angle are consistent with the overall blisk and blade during processing. The shape of the components is matched, and a parameter coupling prediction model is established for the optimize...

Embodiment 2

[0060] refer to Figure 1-5 , a flexible grinding and polishing process of an integral blisk for improving the roughness of the outer surface, comprising the following steps:

[0061] S1. Analysis of the flexible grinding and polishing of the overall blisk: In order to avoid the cause of the joint texture caused by the flexible grinding and polishing, the shape of the flexible abrasive is optimized through theoretical calculation and simulation analysis, so that the abrasive is more suitable for the complex blisk / blade Grinding and polishing of free-form surfaces, through calculation and simulation analysis, study the deformation of blisks caused by grinding and polishing, and then optimize the cutting route and tool angle, so that the actual grinding and polishing route and tool angle are consistent with the overall blisk and blade during processing The shapes of similar components fit together, and a parameter coupling prediction model is established for the optimized tool s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com