High-temperature-resistant release ink

A technology with high temperature resistance and release type, which is applied in the field of ink, can solve the problems of ink peeling, achieve the effect of shortening the cycle, saving the amount of pigment, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

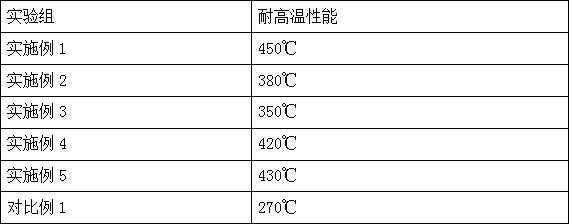

Examples

Embodiment 1

[0017] A kind of high-temperature-resistant light-curable ink, comprising the following components in parts by weight: modified phenolic resin 10, polyurethane modified acrylic resin 35, talc powder 5, mica powder 7, nanometer barium sulfate 10, solvent 23, curing agent 7, Auxiliary agent 3, said auxiliary agent includes 1 part of leveling agent, 1 part of defoamer, and 1 part of dispersant.

[0018] Further, the solvent is isoamyl acetate.

[0019] Further, the curing agent is isophorone diisocyanate.

[0020] The invention provides a high-temperature-resistant release ink, which can solve the problems caused by the stickiness or dry cracking of the ink during high-temperature and high-pressure molding, which leads to the reduction of defects during release.

Embodiment 2

[0022] This embodiment provides a high temperature resistant release ink, which is characterized in that it includes the following components in parts by weight: resin 40, solvent 15, curing agent 5, auxiliary agent 3, and functional filler 12.

[0023] Further, the resin is polyurethane modified acrylic resin.

[0024] Further, the solvent is butanol.

[0025] Further, the curing agent is hexamethylenetetramine.

[0026] Further, the auxiliary agent includes 1 part of leveling agent, 1 part of defoamer, and 1 part of dispersant.

[0027] Further, the functional filler is nano barium sulfate.

Embodiment 3

[0029] This embodiment provides a high temperature resistant release ink, which is characterized in that it includes the following components in parts by weight: resin 58, solvent 27, curing agent 10, auxiliary agent 5, and functional filler 33.

[0030] Further, the resin is a modified phenolic resin.

[0031] Further, the solvent is dipropylene glycol dimethyl ether.

[0032] Further, the curing agent is isophorone diisocyanate.

[0033] Further, the auxiliary agent includes 1.5 parts of leveling agent, 1.5 parts of defoamer, and 2 parts of dispersant.

[0034] Further, the functional filler is a combination of mica powder and nano barium sulfate, including mica powder 8 and nano barium sulfate 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com