CaCO3 surface treatment method for high-filling PBAT biodegradable film and preparation method of film

A biodegradation and surface treatment technology, used in biological packaging, applications, household appliances, etc., can solve the problems of ecological environment and human life hazards, difficult to degrade, pollute the air, etc., to improve process defects, easy operation, and preparation technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

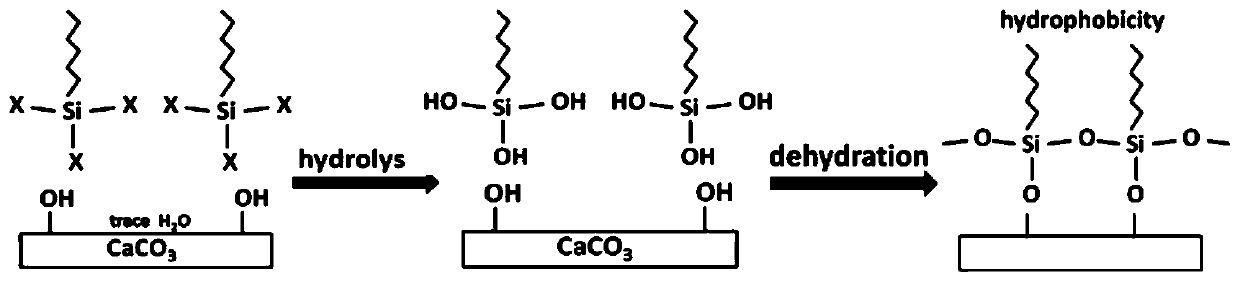

Method used

Image

Examples

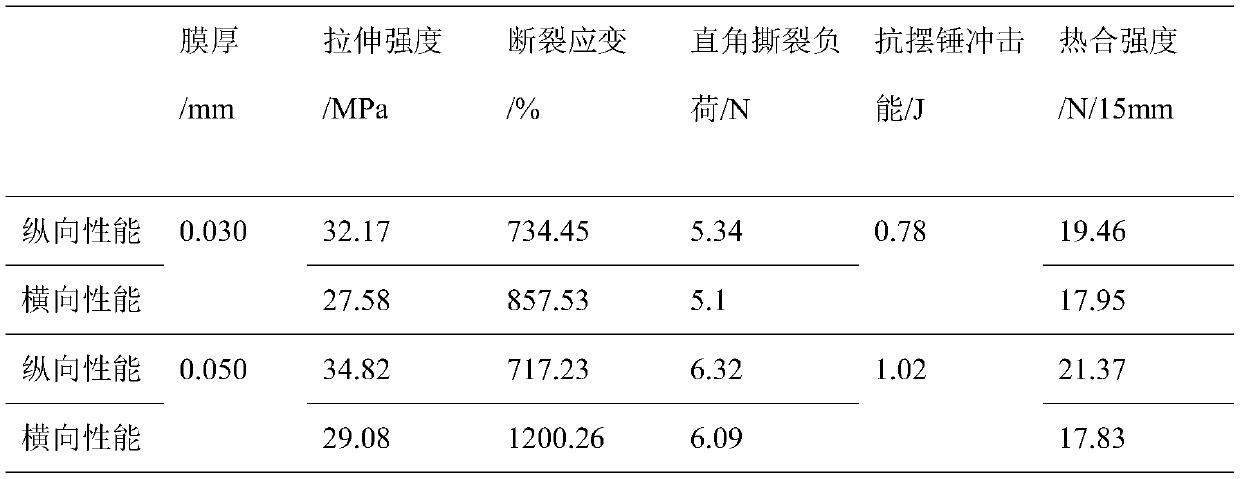

Embodiment 1

[0030] 3000 mesh CaCO 3 As filler filling PBAT to prepare composite material, its preparation process is as follows:

[0031] (1) Dry PBAT at a temperature of 80°C for 8 hours; for 3000 mesh CaCO3 For surface treatment, the surfactant was dissolved in isopropanol in a glass reactor, and then different meshes of CaCO 3 Pour into the solution, stir at room temperature for 2 hours, then add isopropanol to stir, filter, volatilize isopropanol at 85°C, and dry to obtain surface-treated CaCO 3 , at room temperature the surface-treated CaCO 3 Stir in a self-friction high mixer until the temperature of the self-friction high mixer rises to 100°C to remove CaCO 3 Small and medium molecular impurities and moisture, and then put the dispersant, PBAT, chain extender, lubricant and antioxidant into the self-friction high mixer, and continue to blend for 8 minutes.

[0032] (2) Put the mixture into a twin-screw extruder to extrude, cool and pelletize to obtain the required pellets. The ...

Embodiment 2

[0048] 2300 mesh CaCO 3 As filler filling PBAT to prepare composite material, its preparation process is as follows:

[0049] (1) Dry the PBAT at a temperature of 80°C for 8 hours; for 2300 mesh CaCO 3 For surface treatment, the surfactant was dissolved in isopropanol in a glass reactor, and then different meshes of CaCO 3 Pour into the solution, stir at room temperature for 2 hours, then add isopropanol to stir, filter, volatilize isopropanol at 85°C, and dry to obtain surface-treated CaCO 3 , at room temperature the surface-treated CaCO 3 Stir in a self-friction high mixer until the temperature of the self-friction high mixer rises to 100°C to remove CaCO 3 Small and medium molecular impurities and moisture, and then put the dispersant, PBAT, chain extender, lubricant and antioxidant into the self-friction high mixer, and continue to blend for 8 minutes.

[0050] (2) Put the mixture into a twin-screw extruder to extrude, cool and pelletize to obtain the required pellets....

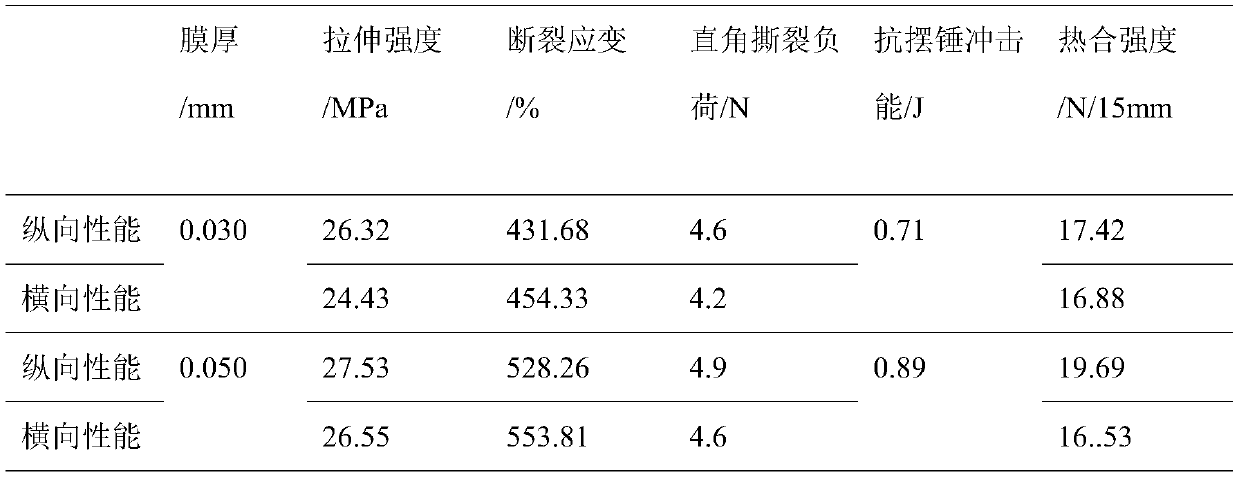

Embodiment 3

[0066] 1250 mesh CaCO 3 As filler filling PBAT to prepare composite material, its preparation process is as follows:

[0067] (1) Dry PBAT at a temperature of 80°C for 8 hours; for 1250 mesh CaCO 3 For surface treatment, the surfactant was dissolved in isopropanol in a glass reactor, and then different meshes of CaCO 3 Pour into the solution, stir at room temperature for 2 hours, then add isopropanol to stir, filter, volatilize isopropanol at 85°C, and dry to obtain surface-treated CaCO 3 , at room temperature the surface-treated CaCO 3 Stir in a self-friction high mixer until the temperature of the self-friction high mixer rises to 100°C to remove CaCO 3 Small and medium molecular impurities and moisture, and then put the dispersant, PBAT, chain extender, lubricant and antioxidant into the self-friction high mixer, and continue to blend for 8 minutes.

[0068] (2) Put the mixture into a twin-screw extruder to extrude, cool and pelletize to obtain the required pellets. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com