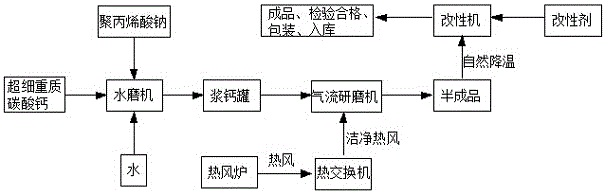

Production process for heavy nano calcium carbonate

A technology of nano calcium carbonate and heavy calcium carbonate, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, calcium/strontium/barium compounds, etc., can solve the problems of inability to large-scale application, large production investment and high power consumption, Achieve the effect of considerable product quality performance, low overall energy consumption, and overall quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take 80kg of superfine heavy calcium carbonate, 35kg of water and 0.5kg of sodium polyacrylate into the water mill, mix and stir, and grind for 15 minutes to prepare calcium slurry, and preheat clean hot air into the airflow grinder until the temperature in the airflow grinder reaches At 360°C, inject the slurry calcium according to the volume ratio of the slurry flow rate to the air flow rate of 1:50, dry and grind at 355°C for 20 minutes to obtain a semi-finished product with nano-scale particle size; when the temperature of the semi-finished product drops to 50°C, send it into Modification machine, add 1840 octadecanoic acid of 10% by weight of the semi-finished product for modification. After the modification is completed, the finished product of heavy nano-calcium carbonate can be obtained, which can be inspected, packaged and put into storage.

Embodiment 2

[0019] Take 100kg of ultra-fine heavy calcium carbonate, 35kg of water and 0.8kg of sodium polyacrylate into the water mill, mix and stir, and grind for 20 minutes to prepare calcium slurry, and feed clean hot air into the airflow grinder to preheat until the temperature in the airflow grinder reaches At 380°C, inject the slurry calcium according to the volume ratio of the slurry flow rate to the air flow rate of 1:80, dry and grind at 370°C for 30 minutes to obtain a semi-finished product with nano-scale particle size; when the temperature of the semi-finished product drops to 80°C, send it into Modification machine, add 1840 octadecanoic acid of 20% by weight of the semi-finished product for modification. After the modification is completed, the finished product of heavy nano-calcium carbonate can be obtained, which can be inspected, packaged and put into storage.

Embodiment 3

[0021] Take 1800kg of ultra-fine heavy calcium carbonate, 300kg of water and 0.6kg of sodium polyacrylate into the water mill, mix and stir, and grind for 18 minutes to prepare calcium slurry, and pass clean hot air into the airflow grinder to preheat until the temperature in the airflow grinder reaches 370 ℃, according to the volume ratio of slurry flow and air flow 1:60, inject the calcium slurry, dry and grind at 370 ℃ for 25 minutes to obtain semi-finished products with nano-scale particle size; when the temperature of semi-finished products drops to 65 ℃, send them into the Add 15% 1840 octadecanoic acid to the semi-finished product for modification. After the modification is completed, the finished product of heavy nano-calcium carbonate can be obtained, which can be inspected, packaged and put into storage.

[0022] In the present invention, a certain amount of ultrafine heavy calcium carbonate, water and sodium polyacrylate are ground and mixed through a water mill in p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com