Cefmenoxime hydrochloride micro-powder and preparation method and device thereof

A technology of cefmenoxime hydrochloride and jet mill, which is applied in grain processing, organic chemistry, etc., can solve the problems of high stirring speed, long dissolution time, and difficulty in preparing injections, so as to reduce related substances, reduce crystallization speed, and dissolve fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be described in detail below.

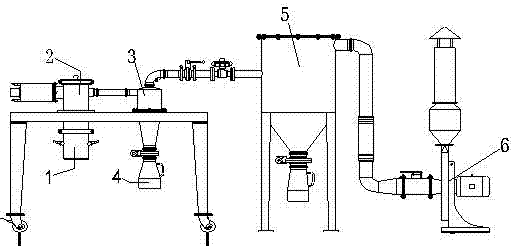

[0023] like figure 1 A kind of device that is used for the micronization of cefmenoxime hydrochloride raw material is shown, and this device comprises jet pulverizer 1, classifying chamber 2, cyclone separator 3, raw material collecting bucket 4, dust collector 5 and induced draft fan 6, described classification The chamber 2 is set on the upper side of the jet mill, the outlet of the classification chamber 2 is connected to the cyclone separator 3 through a pipeline, the lower outlet of the cyclone separator 3 is connected to the raw material collection barrel 4, and the upper outlet of the cyclone separator 3 The dust collector 5 is connected through a pipeline, and the induced draft fan 6 is connected with the above dust collector 5 through a pipeline.

[0024] The operation steps of the above-mentioned device are:

[0025] 1. Turn on the compressed air to ensure that the compress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com