Preparation method of calcium carbonate whiskers by aluminic acid ester and sodium stearate in situ modification

A technology of calcium carbonate whisker and sodium stearate, applied in the direction of fibrous filler, dyed low molecular organic compound treatment, etc., can solve the problem of large amount of modification modifier, non-concentrated product particle size, poor coating effect, etc. problem, to achieve the effect of small usage, improved overall physical performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

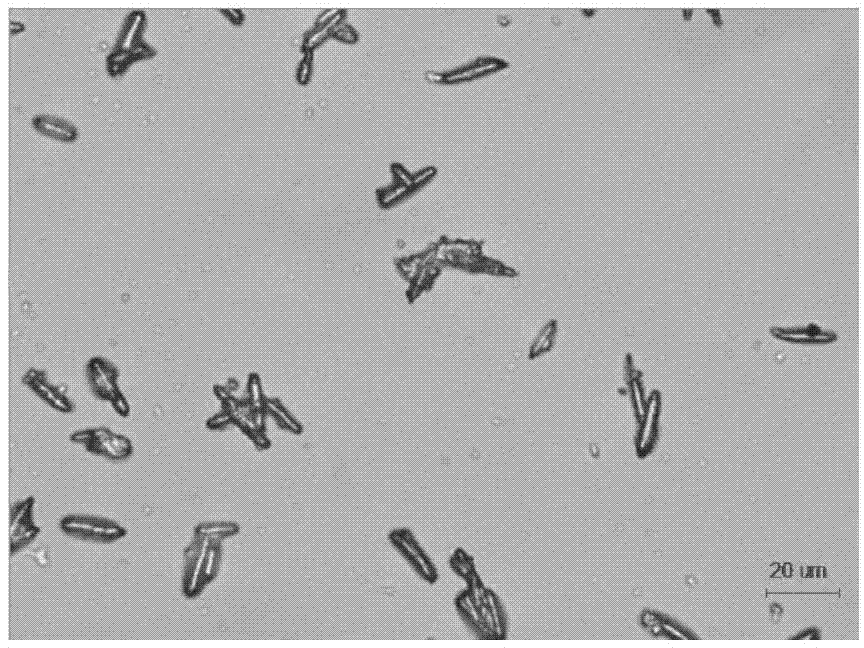

[0021] Under the conditions of 80°C and stirring speed of 900 rpm, the magnesium chloride solution was added in advance to the calcium hydroxide slurry with a mass concentration of 1.5% after being digested and aged for 12 hours after being filtered through a 200-mesh sieve, and the mixture was The molar ratio of magnesium to calcium is 2.5, mixing and stirring for 10 minutes, and at a rate of 100 liters / minute, a gas with a volume ratio of 1:3 of carbon dioxide and nitrogen is introduced to carry out carbonization reaction, and when the carbonation rate is 20%, add Quality is 3% aluminate of calcium hydroxide slurry quality and quality is that the sodium stearate of 1% of calcium hydroxide slurry quality is modified, when reaction solution pH reaches 7, continue aeration after 30 minutes for reaction End point: washing the reaction solution, suction filtering, and drying at 110° C. for 5 hours to obtain functional calcium carbonate whiskers.

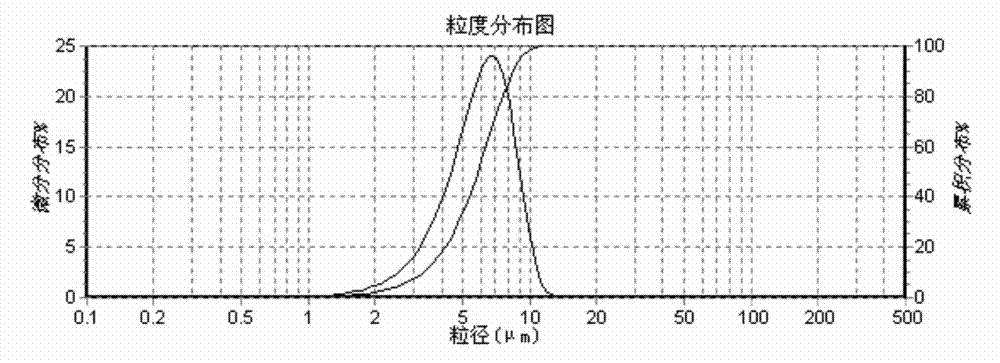

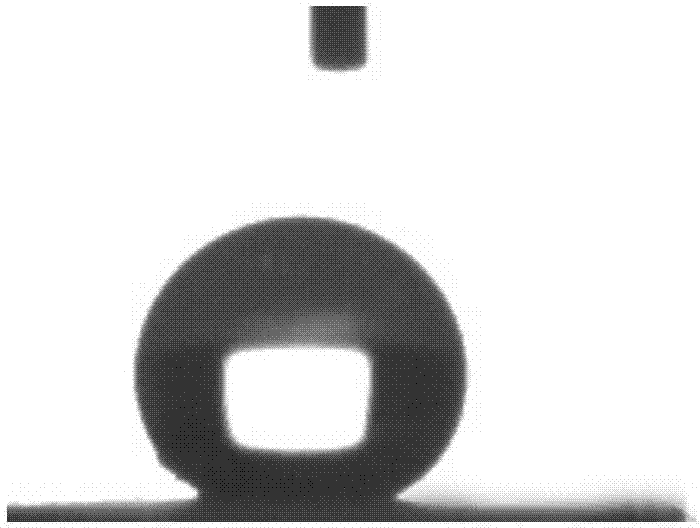

[0022] The aspect ratio of the m...

Embodiment 2

[0024] Under the conditions of 70°C and stirring speed of 600 rpm, the magnesium chloride solution was added in advance to the calcium hydroxide slurry with a mass concentration of 1.5% after being digested and aged for 12 hours after being filtered through a 200 mesh sieve, and the mixture was The molar ratio of magnesium to calcium is 2.0, mixing and stirring for 10 minutes, and at a rate of 90 liters / minute, a gas with a volume ratio of 1:3 of carbon dioxide and nitrogen is introduced to carry out carbonization reaction, and when the carbonation rate is 60%, add The quality is 1% of the aluminate of calcium hydroxide slurry quality and the quality is 1% sodium stearate of calcium hydroxide slurry quality to carry out modification, when reaction liquid pH reaches 7, continue ventilating for 30 minutes and then react End point: washing the reaction solution, suction filtering, and drying at 110° C. for 5 hours to obtain functional calcium carbonate whiskers.

[0025] The aspe...

Embodiment 3

[0027] Under the conditions of 80°C and a stirring speed of 750 rpm, add magnesium chloride solution in advance to the calcium hydroxide slurry with a mass concentration of 0.5% after digestion and aging for 12 hours after filtering through a 200 mesh sieve, and make the mixture The molar ratio of magnesium to calcium is 1.0, mixing and stirring for 10 minutes, and under the condition of a speed of 80 liters / minute, a gas with a volume ratio of carbon dioxide and nitrogen of 1:3 is introduced to carry out carbonization reaction, and when the carbonation rate is 100%, add Quality is 2% aluminate of calcium hydroxide slurry quality and quality is the sodium stearate of 1% of calcium hydroxide slurry quality to carry out modification, when reaction solution pH reaches 7, continue aeration after 30 minutes for reaction End point: washing the reaction solution, suction filtering, and drying at 110° C. for 5 hours to obtain functional calcium carbonate whiskers.

[0028] The aspect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com