Surface-modified ground calcium carbonate suitable for artificial stone fillers

A ground calcium carbonate, surface modification technology, applied in the field of heavy calcium carbonate preparation, to achieve the effects of large specific surface area, good dispersion and compatibility, and high activation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of surface-modified heavy calcium carbonate suitable for artificial stone fillers comprises the following steps: the ore is washed and crushed, adding auxiliary agent A and auxiliary agent B in a screw conveyor to make a paste, and entering into a grinding equipment for grinding. After classification by the speed classifier, calcium carbonate with a particle size distribution suitable for artificial stone is collected.

[0022] In order to make the calcium carbonate special for artificial stone meet the production requirements, the present invention has screened the optimal additive type, consumption, and the control parameters of the vertical mill, as follows:

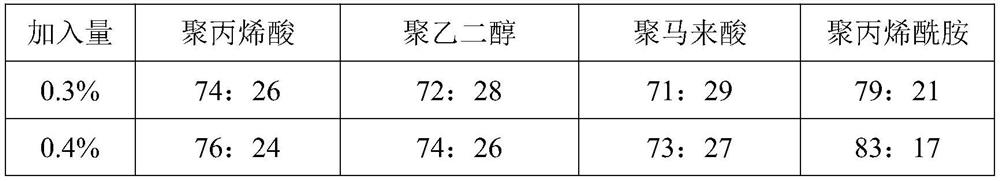

[0023] (1) The type and dosage screening research test of the best additive A

[0024] The study found that the type and amount of additive A (titanate coupling agent, silane coupling agent, aluminate coupling agent, zircoaluminate coupling agent) have little effect on the product finenes...

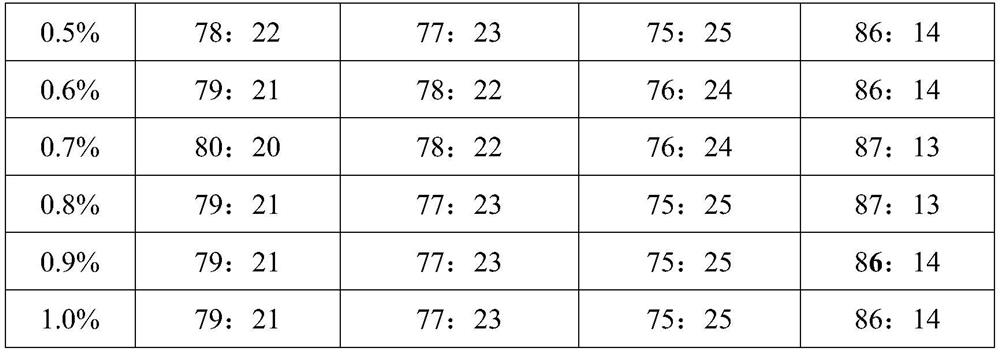

Embodiment 1

[0041] A surface-modified heavy calcium carbonate suitable for artificial stone fillers, comprising the following raw materials: ore, titanate coupling agent, polyacrylamide, and its preparation method includes the following steps: after the ore is cleaned, it is crushed until the particles are less than 28mm , add titanate coupling agent of 1% ore mass and 0.5% ore mass polyacrylamide to the screw conveyor to make a paste and enter the vertical mill grinding equipment for grinding. During grinding, the oil pressure of the grinding roller is 5MPa. Classifier classification, speed classifier speed is 380-400r / min, the collected particle size distribution (D97=100-110 μm, D50=11-12 μm) is suitable for surface modification of artificial stone filler ground calcium carbonate.

Embodiment 2

[0043] A surface-modified heavy calcium carbonate suitable for artificial stone fillers, comprising the following raw materials: ore, titanate coupling agent, polyacrylamide, and its preparation method includes the following steps: after the ore is cleaned, it is crushed until the particles are less than 30mm , add 0.8% titanate coupling agent of ore mass and 0.6% polyacrylamide of ore mass in the screw conveyor to make a paste and enter the vertical mill grinding equipment for grinding. The oil pressure of the grinding roller is 6.5MPa during grinding. Speed classifier classification, the speed classifier speed is 420-430r / min, the collected particle size distribution (D97=70-80 μm, D50=5-6 μm) is suitable for surface modification of artificial stone filler ground calcium carbonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com