Self-repair solution, preparation method and use method thereof

A self-healing and solution technology, used in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of easy agglomeration and precipitation of micro-nano materials, high cost of self-healing solutions, loss of friction-reducing and self-healing functions, etc., and achieves good dispersion stability. performance, easy to promote and apply, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

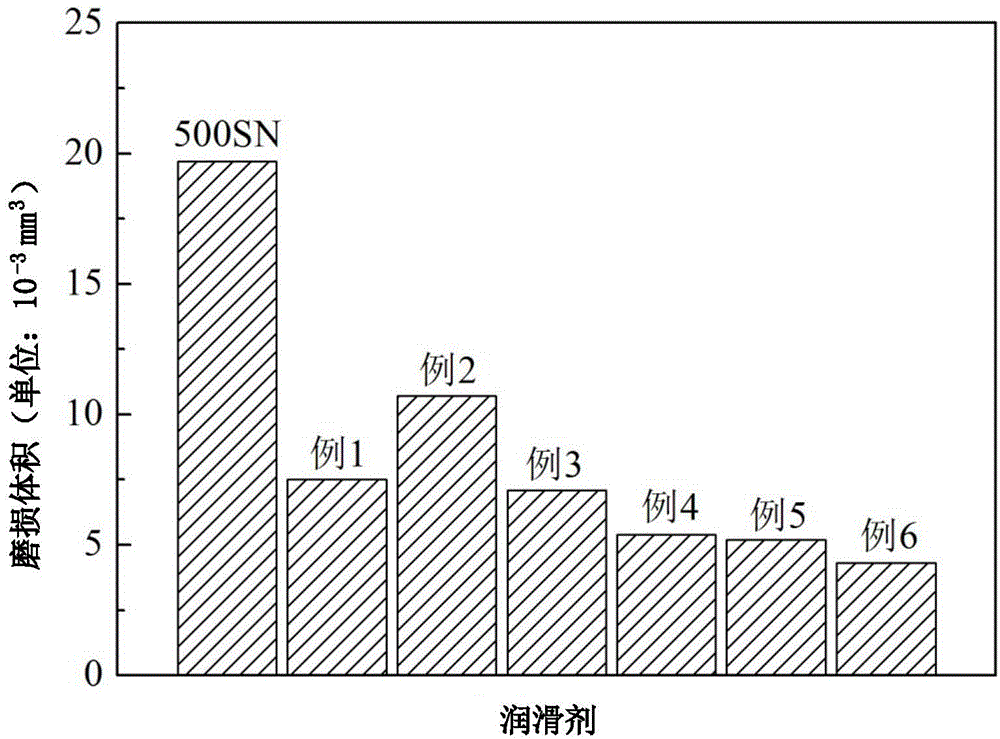

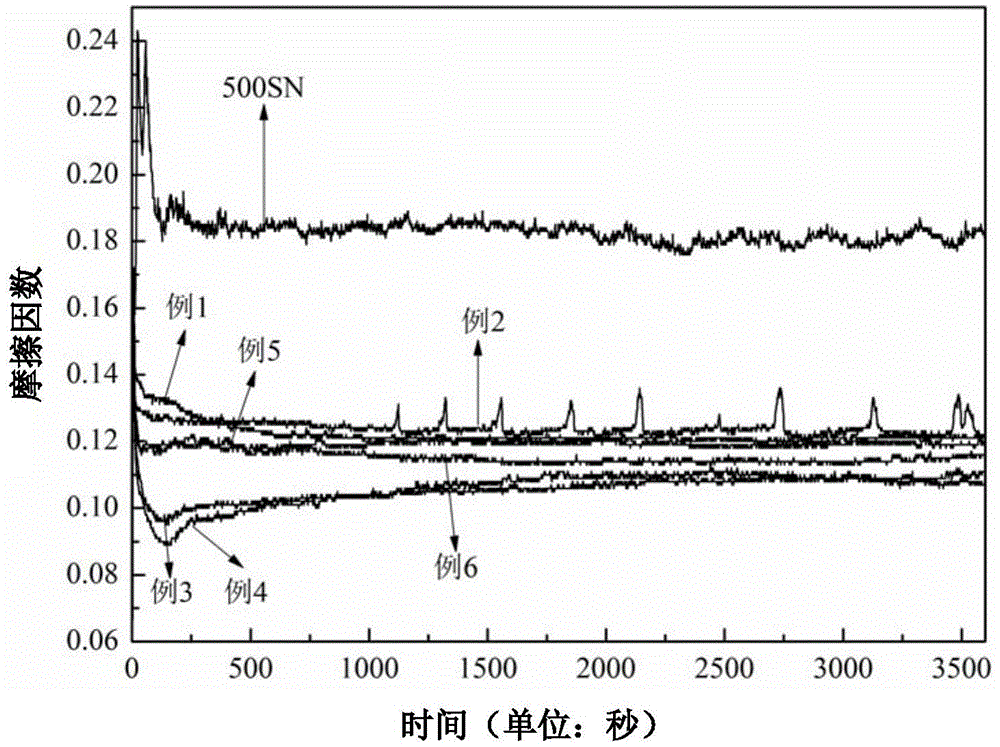

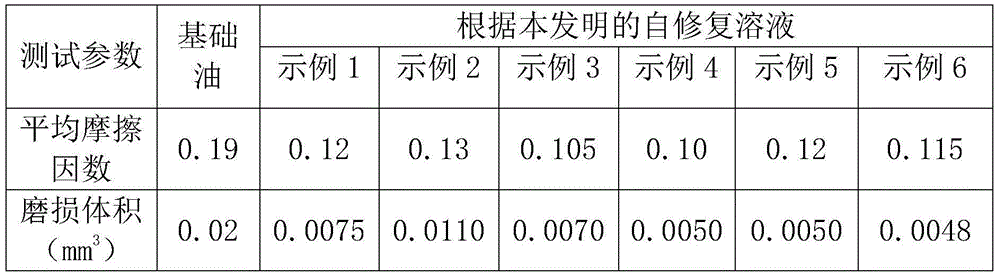

[0031] Referring to the accompanying drawings, the present invention will be further described in detail in conjunction with the embodiments. Unless otherwise specified, the percentages of raw materials in the following examples are mass percentages.

[0032] [Components of the self-healing solution according to the present invention]

[0033] According to the self-repairing solution of the present invention, nano-silicate (nano-attapulgite and nano-lanthanum oxide) and nano-metal material (nano-copper alloy) are added as self-repairing materials, with base oil as solvent, and a small amount of catalyst, surface Modifiers, dispersants and other materials.

[0034] Specifically, the mass percent content of the self-repairing solution according to the present invention consists of: 2% to 30% of nano attapulgite powder, 1% to 30% of nano copper alloy, 0.5 to 5% of nano lanthanum oxide, 0.5%-5% oleic acid, 1%-10% dispersant and 50%-95% base oil.

[0035] Among them, the nano at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com