Anti-wear, anti-friction and stable-dispersion lubricating oil or lubricating grease and preparation method thereof

A technology for stable dispersion and lubricating oil, applied in lubricating compositions, petroleum industry, additives, etc., can solve problems such as weak correlation, achieve reduced wear, significant operating comfort, long-term dispersion stability and complex environment dispersion stability Sex-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

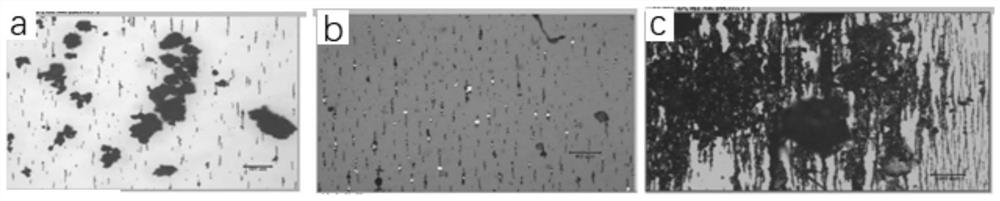

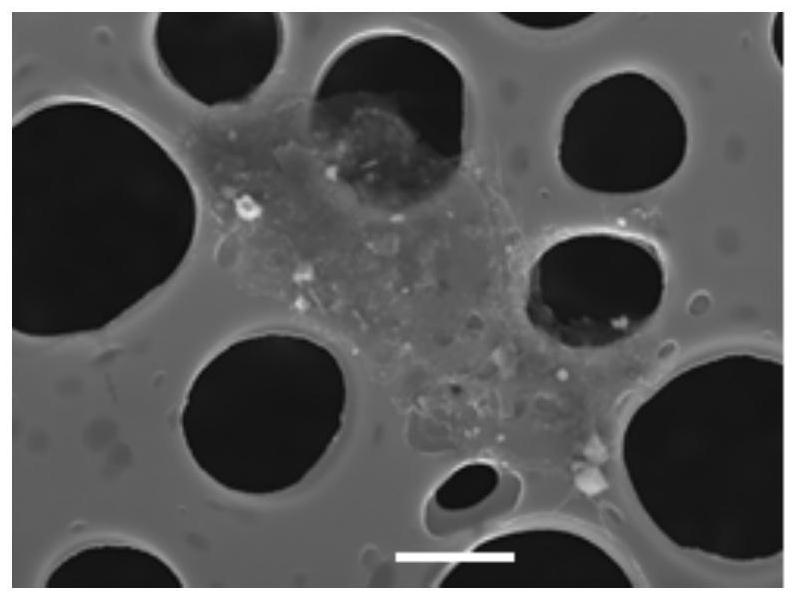

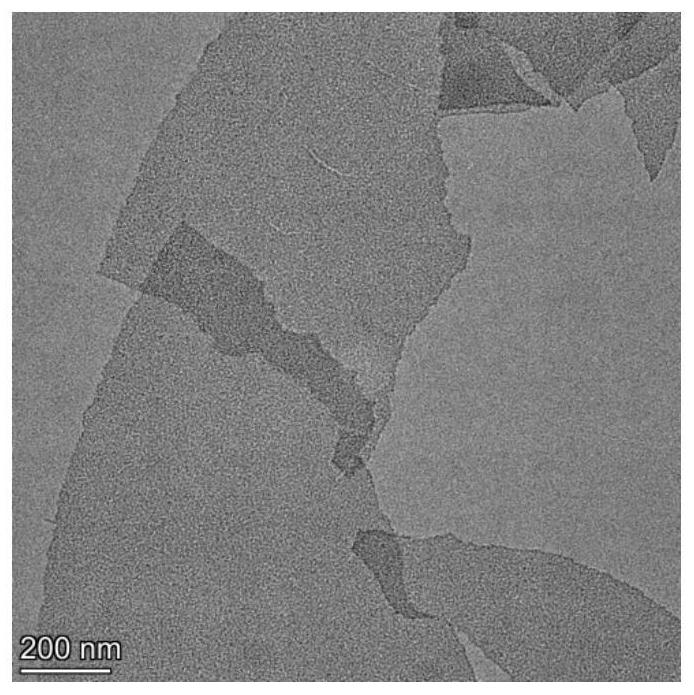

Image

Examples

Embodiment 1

[0046] This embodiment provides a hydraulic oil with anti-wear, anti-friction and dispersion stability properties, which is HM-46 hydraulic oil added with docosyl chain-branched sulfonated graphene. Wherein, the added quality of the sulfonated graphene of docosyl chain branch is 0.03% of HM-46 hydraulic oil; for 23.

[0047] Its preparation method is:

[0048] (1) Stir and disperse the sulfonated graphene of eicosyl chain branch in the base oil of HM-46 hydraulic oil, make graphene additive, mass fraction is 5%, dispersion time is 20min, and heating temperature is 30 °C, the stirring speed is 3000r / min;

[0049] (2) Mix the graphene additive prepared in step (1) with HM-46 hydraulic oil, stir and distribute, and disperse for 40 min at 100 r / min to obtain the anti-wear, friction-reducing and stable dispersion hydraulic oil.

Embodiment 2

[0051] This embodiment provides a transmission oil with anti-wear, anti-friction and dispersion stability properties, which is No. 8 hydraulic transmission oil added with docosyl chain-branched sulfonated graphene. Wherein, the added quality of the sulfonated graphene branched by docosyl chain is 0.02% of No. 8 hydraulic transmission oil; The ratio is 23.

[0052] Its preparation method is:

[0053] (1) the sulfonated graphene pulse of eicosyl chain branch is dispersed in the base oil of No. 8 hydraulic transmission oil, makes graphene additive, and mass fraction is 5%, and dispersion time is 20min, and heating temperature is 30°C, the stirring speed is 3000r / min;

[0054] (2) Mix the graphene additive prepared in step (1) with No. 8 hydraulic transmission oil, pulse disperse, and disperse for 40 min at 100 r / min to obtain the anti-wear, friction-reducing and stable-dispersion hydraulic transmission oil.

Embodiment 3-10

[0056] This embodiment provides eight kinds of hydraulic oils with anti-wear, anti-friction and dispersion stability properties, which are HM-46 hydraulic oils added with sulfonated graphene branched by long carbon straight chains. In Examples 3-10, the mass ratios of carbon elements and sulfur elements in the sulfonated graphene grafted with long carbon direct chains are 10, 15, 17, 19, 25, 30, 35, and 40 in sequence. For the preparation method, refer to the method in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com