Gasoline engine lubricating coil composition and preparation method thereof

A technology for lubricating oil composition and gasoline engine, which is applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of reducing the efficiency of catalysts, poisoning catalysts, and restricting specifications and standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

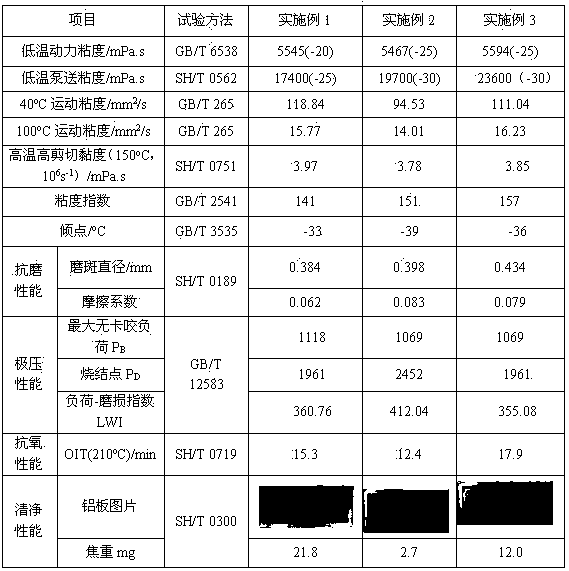

Examples

Embodiment 1

[0068] A gasoline engine lubricating oil composition (I), comprising:

[0069] Base oil: a mixture of 150N and 500N in a mass ratio of 1:2 85.429%

[0070] Dispersant: a mixture of T154 and T161 at a mass ratio of 1:1 2.5%

[0071] Detergent: a mixture of high-basic calcium sulfonate and medium-basic calcium salicylate at a mass ratio of 3:1 1.8%

[0072] Oil-soluble or dispersed oil-stable boron-containing compound: boronated succinimide 0.5%

[0073] Oil-soluble or dispersed oil-stable molybdenum-containing compound: Molybdenum succinimide 0.3%

[0074] Zinc dialkyldithiophosphate: a mixture of T209 and T203 in a mass ratio of 3:1 0.6%

[0075] Antioxidant: a mixture of phenolic ester type antioxidant and alkylated diphenylamine at a mass ratio of 1:3 0.25%

[0076] Rust inhibitor: T706 0.1%

[0077] Pour point depressant: T602 0.02%

[0078] Antifoaming agent: T921 0.001%

[0079] Viscosity index improver: SV261 8.5%

Embodiment 2

[0081] A gasoline engine lubricating oil composition (II), comprising:

[0082] Base oil: a mixture of 150N and 250N in a mass ratio of 1:4 85.929%

[0083] Dispersant: a mixture of T151 and T161 at a mass ratio of 1:1 3.3%

[0084] Detergent: a mixture of high base value calcium sulfonate and medium base value sulfurized alkylphenate calcium in a mass ratio of 2:1 1.6%

[0085] Oil-soluble or dispersed oil-stable boron-containing compound: Calcium boronated sulfonate 0.6%

[0086] Oil-soluble or dispersed oil-stable molybdenum-containing compound: Molybdenum succinimide 0.3%

[0087] Zinc dialkyldithiophosphate: T203 0.5%

[0088] Antioxidant: a mixture of phenolic ester type antioxidant and alkylated diphenylamine at a mass ratio of 1:3 0.25%

[0089] Rust inhibitor: T706 0.1%

[0090] Pour-point depressant: 1-248 0.02%

[0091] Antifoaming agent: T921 0.001%

[0092] Viscosity Index Improver: 7067C 9.0%

Embodiment 3

[0094] A gasoline engine lubricating oil composition (III), comprising:

[0095] Base oil: a mixture of 150N and 500N in a mass ratio of 2:3 85.629%

[0096] Dispersant: a mixture of T154 and T161 at a mass ratio of 1:3 3.5%

[0097] Detergent: a mixture of high-basic calcium sulfonate and medium-basic calcium salicylate at a mass ratio of 2:1 1.8%

[0098] Oil-soluble or dispersed oil-stable boron-containing compound: boronated succinimide 0.6%

[0099] Oil-soluble or dispersed oil-stable molybdenum-containing compound: Molybdenum-succinimide 0.5%

[0100] Zinc dialkyldithiophosphate: a mixture of T209 and T203 in a mass ratio of 3:1 0.6%

[0101] Antioxidant: a mixture of phenolic ester type antioxidant and alkylated diphenylamine at a mass ratio of 1:3 0.25%

[0102] Rust inhibitor: T746 0.1%

[0103] Pour point depressant: T602 0.02%

[0104] Antifoaming agent: T921 0.001%

[0105] Viscosity index improver: SV260 7.0%

[0106] The preparation method of above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com