Antioxidant composition and lubricating oil composition

A technology of antioxidant and composition, which is applied in the direction of lubricating composition, additives, petroleum industry, etc., can solve the problems of weakening the anti-wear and anti-friction effect of organic molybdenum additives, shortening the service life of lubricating oil, and unfavorable anti-oxidation synergy, etc. Achieve excellent anti-wear and anti-friction performance, improve anti-oxidation performance and anti-wear and anti-friction performance, excellent anti-oxidation performance and anti-wear and anti-friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

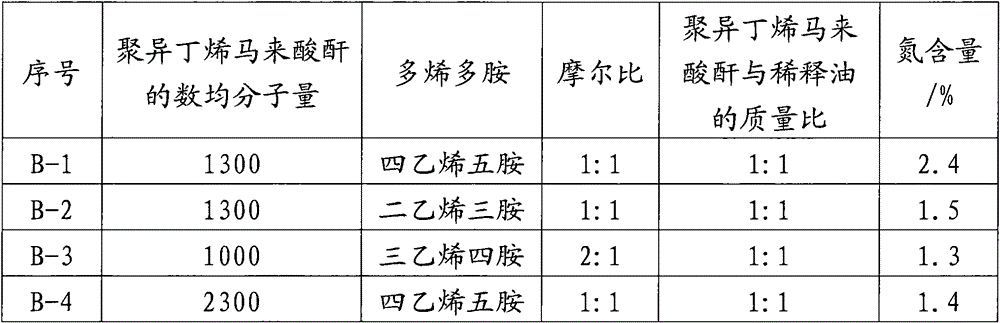

[0070] Add fatty acid amide, polyisobutylene succinimide, inorganic molybdenum compound and optional distilled water, diluent oil and solvent into the reaction vessel, stir, heat up, remove moisture, and react at 120°C-160°C for 1-10 hours, Finally, the solvent is distilled off to obtain the organic molybdenum additives W-01-W-06 respectively, and the mass fraction of the molybdenum content is between 1.0% and 10.0%.

Embodiment 7-12 and comparative example 7-15

[0078] Add arylamine antioxidants and organic molybdenum additives to various lubricating base oils by mass percentage respectively, mix and stir to obtain Examples 7-12 and Comparative Examples 7-15 of the lubricating oil composition, each embodiment and Comparative Example The formulation composition is shown in Table 4.

[0079] The anti-oxidation properties and anti-wear and anti-friction properties of these lubricating oil compositions were evaluated respectively. The PDSC method was used to measure the anti-oxidation performance of each lubricating oil composition. The test conditions were 230°C and the oxygen pressure was 0.5MPa; the SRV method was used to measure the anti-wear and friction-reducing properties of each lubricating oil composition. The test conditions were: temperature 80°C, load 300N, stroke 1mm, test time 1 hour, frequency 50Hz, SRV method see National Energy Administration standard NB / SH / T0847-2010. The test results are shown in Table 5.

[0080] As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com