Antioxidant corrosion inhibitor composition and lubricating oil composition

An anti-oxidant and anti-corrosion agent and composition technology, applied in the fields of lubricating oil compositions and anti-oxidative anti-corrosion agent compositions, can solve the unfavorable synergistic effects of anti-oxidation and anti-wear and anti-friction, shorten the service life of lubricating oil, and cause corrosion It can achieve the effects of excellent anti-wear and anti-friction performance, improved anti-oxidation performance and high conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

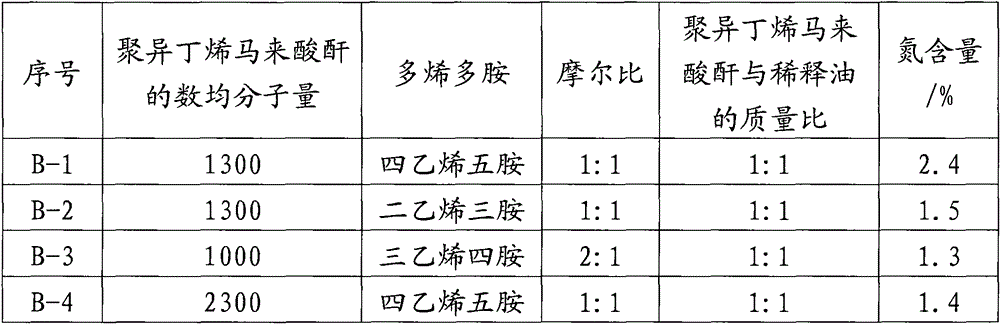

[0074] Add fatty acid amide, polyisobutylene succinimide, inorganic molybdenum compound and optional distilled water, diluent oil and solvent into the reaction vessel, stir, heat up, remove water, and react at 120°C-160°C for 1-10 hours. Finally, the solvent is evaporated to obtain organic molybdenum additives W-01 to W-06, and the mass fraction of the molybdenum content is between 1.0% and 10.0%.

Embodiment 7-12 and comparative example 7-13

[0082] Add aromatic amine antioxidants, thiadiazole derivatives and organic molybdenum additives into various lubricating base oils in mass percentages, and mix and stir to obtain examples 7-12 and comparative examples 7-13 of the lubricating oil composition. The formula composition of the examples and comparative examples is shown in Table 4.

[0083] The anti-oxidation, anti-corrosion and anti-wear and anti-friction properties of these lubricating oil compositions were evaluated respectively. The PDSC method was used to determine the oxygen resistance of each lubricating oil composition, and the test conditions were 230°C, and the oxygen pressure was 0.5MPa; the copper sheet corrosion method was used to determine the corrosion resistance of each lubricating oil composition, and the test conditions were 100°C, 3h; The SRV method determines the anti-wear and anti-friction performance of each lubricating oil composition. The test conditions are: temperature 80℃, load 300N, stroke ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com