Preparation method of carbon fiber and silicon dioxide nanosphere synergically filled ultra-high molecular weight polyethylene wear-resistant material

An ultra-high molecular weight, silicon dioxide technology, applied in the field of nano-tribology, can solve the problems of nano-scale SNS filling macromolecular materials difficult, the enhancement effect is not obvious, etc., to achieve good processing and forming ability, good mortar wear performance, good The effect of friction and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Put a carbon fiber (CF) with a diameter of 1-10 μm and a length of 10-60 μm in a beaker, add an aqueous solution of nitric acid with a concentration of 5-50wt.%, and then carry out a stirring reaction at 25-80°C for 2 hours, and the reaction is completed After suction filtration, the solid phase was washed with deionized water and alcohol for 2 to 3 times, and dried to obtain nitric acid modified carbon fiber (CFN).

[0036] The mixing volume ratio of the above nitric acid aqueous solution and carbon fiber is 2-10:1.

[0037] 2. Weigh 52 g of nitric acid modified carbon fiber (CFN) into a 500 mL round bottom flask, measure 150 mL of ethanol with a graduated cylinder, add it to the flask, and stir magnetically in a water bath at 40°C to make the nitric acid modified carbon fiber ( CFN) was dissolved in ethanol solution, and then 18g tetraethyl orthosilicate (TEOS) was added, and the stirring was continued for 5 min. Slowly drop the ammonia solution into the flask (ab...

Embodiment 2

[0043] Steps 1-3 are the same as the above example.

[0044] Take 2.6g of the obtained coupling-treated composite filler (SNS / CF) and 130g of ultra-high molecular weight polyethylene (molecular weight: 3,000,000-16,000,000), and mix them in a high-speed mixer for 5 minutes to obtain a mixture.

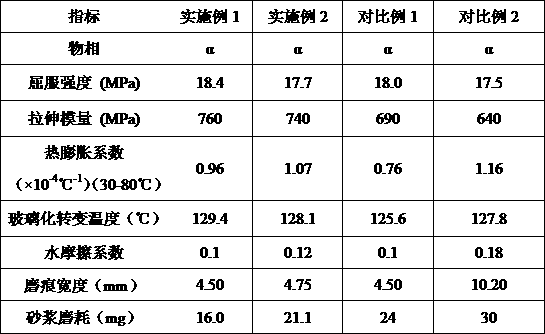

[0045] Take the mixture and press it on a hydraulic press, set the working temperature of the hydraulic press at 190°C, preheat for 15 minutes, press at 10MPa pressure for 10 minutes, and then cold press at room temperature on a flat vulcanizing machine with a working temperature of 60°C and a pressure of 10MPa After 5 minutes, an ultra-high molecular weight polyethylene wear-resistant material co-filled with sheet-like carbon fibers and silica nanospheres was obtained. The main properties of the material are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com