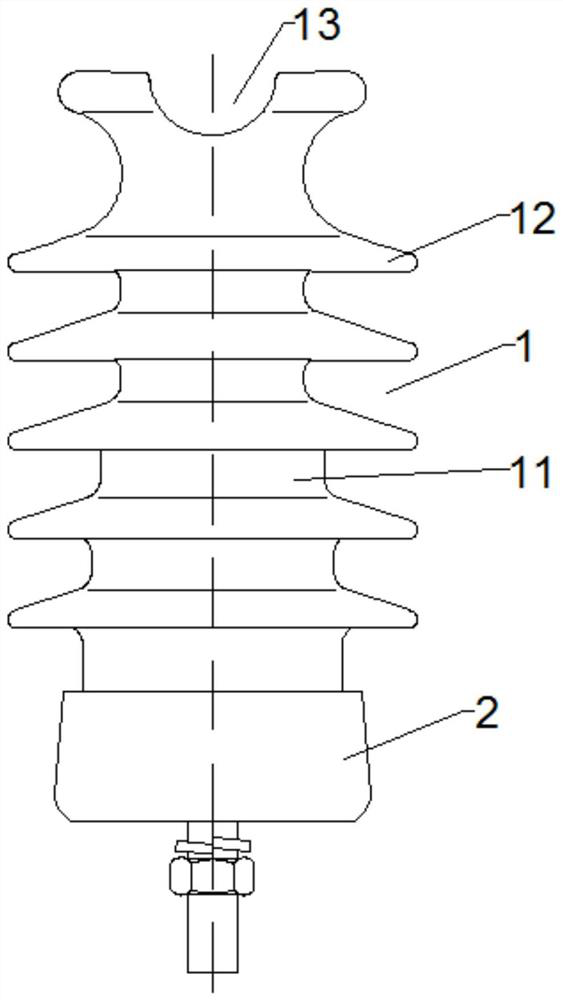

Line column type porcelain insulator and preparation method thereof

A porcelain insulator and column type technology, applied in the field of line column type porcelain insulator and its preparation, can solve the problems of shortening the service life of the ceramic insulator, affecting the normal operation of the railway power grid, increasing the maintenance cost of the insulator, etc., and improving the resistance to salt spray corrosion. , Excellent extreme pressure resistance, the effect of shortening the co-infiltration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of a line post type porcelain insulator, comprising the following steps:

[0045] S1, making mud: by weight, 15 parts of Guangdong clay, 20 parts of semi-mountain clay, 12 parts of left cloud clay, 10 parts of bauxite, 10 parts of zircon, 10 parts of aluminum oxide, 8 parts of talc, and 5 parts of lanthanum hydroxide 5 parts of boric acid, 1 part of carbon powder, and 0.5 parts of water reducing agent are put into a ball mill and added with water for ball milling for 6 hours to obtain coarse mud. Pass the coarse mud through a 200-mesh sieve, and the remaining 0.5% of the sieve is less than 0.5%, and then remove iron-containing impurities to obtain clean mud ; Wherein, the water reducer includes by weight: 20 parts of polydimethylaminoethyl methacrylate, 10 parts of sodium aminotrimethylene phosphonate, 1-butyl-2,3-dimethylimidazole proline salt 5 parts Parts, 5 parts of sodium metasilicate, 1 part of sodium carbonate;

[0046] S2, mud making: the o...

Embodiment 2

[0052] A preparation method of a line post type porcelain insulator, comprising the following steps:

[0053]S1, making mud: by weight, 25 parts of Guangdong mud, 12 parts of semi-mountain mud, 20 parts of left cloud, 18 parts of bauxite, 18 parts of zircon, 15 parts of aluminum oxide, 15 parts of talc, and 12 parts of lanthanum hydroxide 12 parts of boric acid, 5 parts of carbon powder, and 1.5 parts of water reducing agent are put into a ball mill and added with water for ball milling for 6 to 15 hours to obtain coarse mud. Pass the coarse mud through a 300-mesh sieve, and the remaining 0.2% of the sieve is less than 0.2%, and then remove iron-containing impurities to obtain clean Among them, the water reducer includes by weight: 12 parts of polydimethylaminoethyl methacrylate, 6 parts of sodium glutamic acid dimethylidene phosphonate, N-2 hydroxyethyl-N-dimethylidene phosphine 6 parts of sodium phosphate, 6 parts of sodium aminoethylpiperazine trimethylene phosphonate, 5 pa...

Embodiment 3

[0060] A preparation method of a line post type porcelain insulator, comprising the following steps:

[0061] S1, making mud: by weight, 22 parts of Guangdong clay, 15 parts of semi-mountain clay, 13 parts of left cloud clay, 12 parts of bauxite, 12 parts of zircon, 13 parts of aluminum oxide, 10 parts of talc, and 7 parts of lanthanum hydroxide 7 parts of boric acid, 2 parts of carbon powder, and 1 part of water reducing agent are put into a ball mill and added with water for ball milling for 8 hours to obtain coarse mud. Pass the coarse mud through a 25-mesh sieve, and the remaining 0.3% of the sieve is removed, and then the iron-containing impurities are removed to obtain clean mud ; Wherein, the water reducer includes by weight: 15 parts of polydimethylaminoethyl methacrylate, 6 parts of sodium diethylene triamine pentamethylene phosphonate, 6 parts of sodium piperazine dimethyl phosphonate, 1-ethylidene 4 parts of base-3-methylimidazolium alanine salt, 4 parts of butylsul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com