Special lubricating grease for caliper guide pin

A guide pin and grease technology, which is applied in the field of grease, can solve the problems of inability to improve the fretting wear of the caliper guide pin, low friction coefficient, and aggravated fretting wear, and achieve improved anti-fretting wear performance, active chemical properties, The effect of increasing the extreme pressure value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

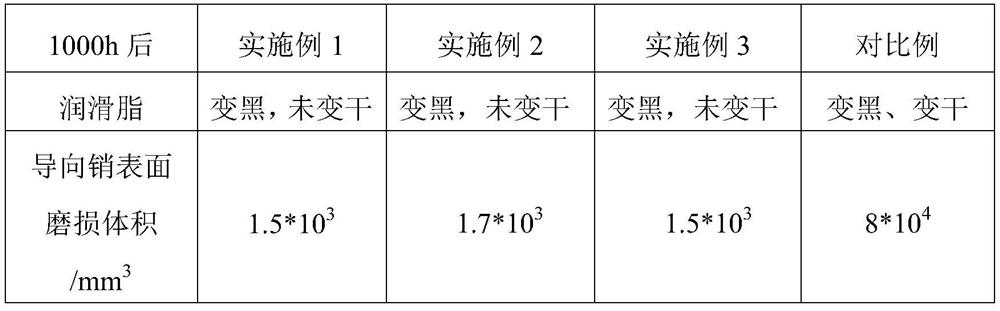

Examples

Embodiment 1

[0034] A special lubricating grease for caliper guide pins provided by the present invention includes the following components in parts by mass: 82 parts of base oil, 0.5 parts of nano-scale sulfide additive, 1.65 parts of extreme pressure agent, 2 parts of corrosion inhibitor, thickened 7 parts of agent, 0.5 part of peptizer, and 0.5 part of antioxidant.

[0035] In this embodiment: the base oil is a commercially available PAG polyether synthetic base oil; the nanoscale sulfide additive is copper sulfide nanoparticles, with an average particle diameter of 25 to 30 nm; the extreme pressure agent is aminothioester (commercially available products for short T323); the corrosion inhibitor is benzotriazole; the thickener is lithium lauryl hydroxystearate, dilithium azelate, and palmitic acid in a mass ratio of 4:3.5:0.5; the peptizer is diiso Octylamine; the antioxidant is N-phenyl-α-naphthylamine.

Embodiment 2

[0037] A special lubricating grease for caliper guide pins provided by the present invention comprises the following components in parts by mass: 85 parts of base oil, 0.2 parts of nano-scale sulfide additive, 2 parts of extreme pressure agent, 1.5 parts of corrosion inhibitor, thickener 6 parts of chemical agent, 0.4 part of peptizer, and 0.4 part of antioxidant.

[0038] In this embodiment: the base oil is a PAG polyether synthetic base oil; the nanoscale sulfide additive is a mixture of nickel sulfide nanoparticles and zinc sulfide nanoparticles (the mass ratio of nickel sulfide nanoparticles and zinc sulfide nanoparticles is 3:7 ), the average particle size is 25-30nm; the extreme pressure agent is aminothioester; the corrosion inhibitor is benzotriazole; the thickener is lithium lauryl stearate, dilithium azelate, palmitic acid Composite with a ratio of 2.9:3:0.1; the peptizer is diisooctylamine; the antioxidant is N-phenyl-α-naphthylamine.

Embodiment 3

[0040] A special lubricating grease for caliper guide pins provided by the present invention comprises the following components in parts by mass: 90 parts of base oil, 0.1 part of nano-scale sulfide additive, 3 parts of extreme pressure agent, 1 part of corrosion inhibitor, thickener 5.6 parts of chemical agent, 0.1 part of peptizer, and 0.1 part of antioxidant.

[0041] In this embodiment: the base oil is a commercially available PAG polyether synthetic base oil; the nanoscale sulfide additive is mixed with copper sulfide nanoparticles and zinc sulfide nanoparticles (the mass ratio of copper sulfide nanoparticles and zinc sulfide nanoparticles is 6:4), the average particle size is 25-30nm; the extreme pressure agent is aminothioester; the corrosion inhibitor is tolyltriazole; the thickener is lithium lauryl stearate and dilithium azelate , Palmitic acid is compounded according to the mass ratio of 2.5:4:0.2; the peptizer is diisooctylamine; the antioxidant is N-phenyl-α-napht...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com