Transmission shaft spline lubricating grease composition and preparation method and application thereof

A grease composition and transmission shaft technology, applied in the field of grease, can solve problems such as poor performance and poor lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment provides a transmission shaft spline grease composition, including a main component and an additive, and the main component includes the following components in weight percentage:

[0058] Base oil (Mobil 500: KZ160=7:3) 85%

[0059] Lithium complex thickener 15%;

[0060] Based on the total mass of the main components, the additive includes the following components in weight percentage:

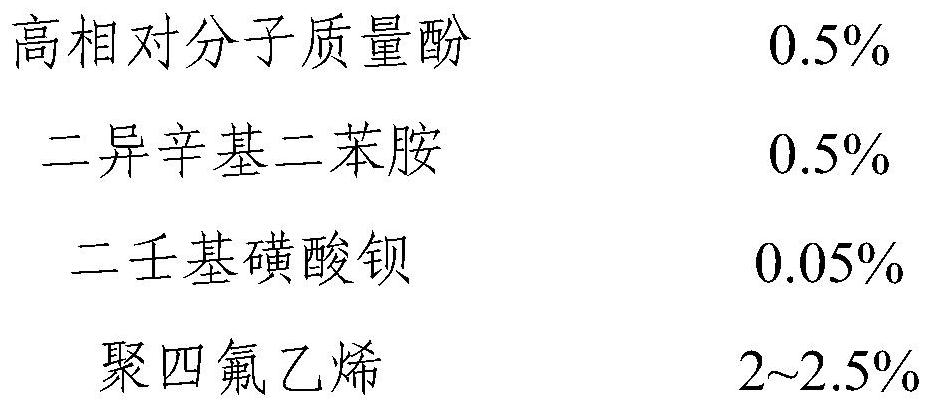

[0061]

[0062] Wherein, the complex lithium thickener is prepared by saponification of fatty acid and alkali at a mass ratio of 150:28.6; the fatty acid is 12-hydroxystearic acid and dodecanedibasic acid, and the 12-hydroxystearic acid The mass ratio of acid to dodecanedibasic acid is 4:1; the base is lithium hydroxide and calcium hydroxide, and the mass ratio of lithium hydroxide to calcium hydroxide is 24.5:4.1.

[0063] The preparation method of described transmission shaft spline grease composition comprises the steps:

[0064] (1) Mix 120g 12-hydroxystearic...

Embodiment 2

[0073] This embodiment provides a transmission shaft spline grease composition, including a main component and an additive, and the main component includes the following components in weight percentage:

[0074] Base oil (Mobil 500: KZ160=7:3) 86%

[0075] Lithium complex thickener 14%;

[0076] Based on the total mass of the main components, the additive includes the following components in weight percentage:

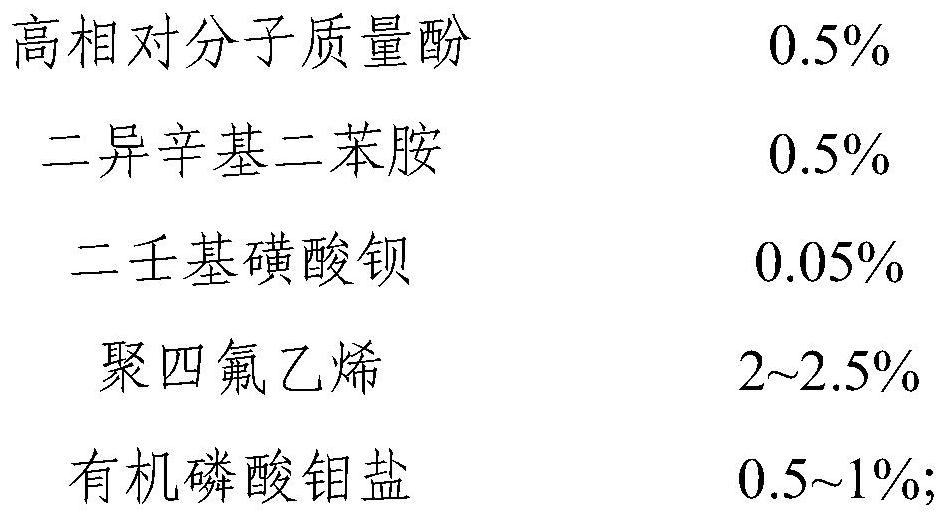

[0077]

[0078] Wherein, the complex lithium thickener is prepared by saponification of fatty acid and alkali at a mass ratio of 140:26.8; the fatty acid is 12-hydroxystearic acid and dodecanedibasic acid, and the 12-hydroxystearic acid The mass ratio of acid to dodecanedibasic acid is 4:1; the base is lithium hydroxide and calcium hydroxide, and the mass ratio of lithium hydroxide to calcium hydroxide is 23:3.8.

[0079] The preparation method of described transmission shaft spline grease composition comprises the steps:

[0080] (1) Mix 112g 12-hydroxystearic a...

Embodiment 3

[0088] This embodiment provides a transmission shaft spline grease composition, including a main component and an additive, and the main component includes the following components in weight percentage:

[0089] Base oil (Mobil 500: KZ160=7:3) 87%

[0090] Lithium complex thickener 13%;

[0091] Based on the total mass of the main components, the additive includes the following components in weight percentage:

[0092]

[0093] Wherein, the complex lithium thickener is prepared by saponification of fatty acid and alkali at a mass ratio of 130:25; the fatty acid is 12-hydroxystearic acid and dodecanedibasic acid, and the 12-hydroxystearic acid The mass ratio of acid to dodecanedibasic acid is 4:1; the base is lithium hydroxide and calcium hydroxide, and the mass ratio of lithium hydroxide to calcium hydroxide is 21.4:3.6.

[0094] The preparation method of described transmission shaft spline grease composition comprises the steps:

[0095] (1) Mix 104g 12-hydroxystearic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solidifying point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com