Method for preparing composite lithium-calcium based grease by using waste lithium based lubricating grease as raw materials

A technology of lithium-based grease and calcium-based grease, which can be used in lubricating compositions, petroleum industry, etc., can solve problems such as environmental pollution, and achieve the effects of reducing environmental pollution, high hardness and excellent high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

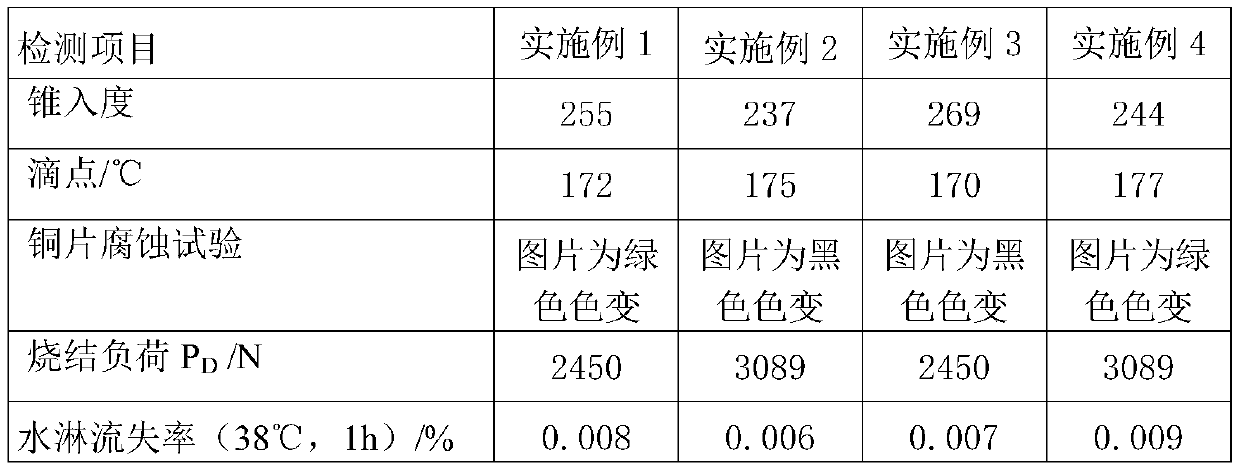

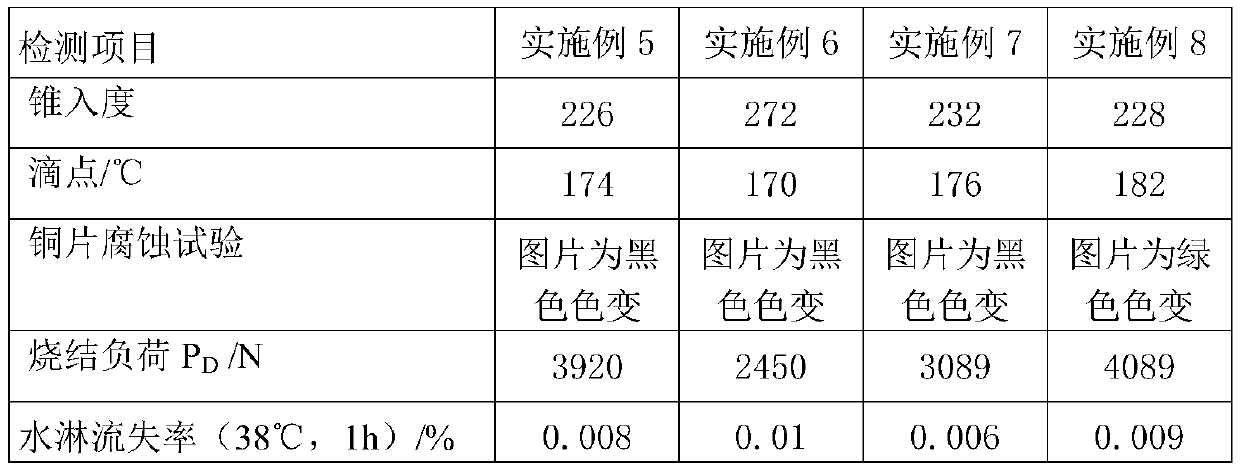

Examples

Embodiment 1

[0044]The preparation method of composite lithium-calcium grease comprises the following steps:

[0045] A. Use 26# industrial grade white oil (40°C kinematic viscosity of 25mm 2 ·s -1 ) to a cone penetration of 430, adopt high-speed centrifugation, filter to remove mechanical impurities, weigh 400.0g and put it into the reactor, and add 24.0g of 12-hydroxystearic acid and 6.0g of stearic acid to the reactor in turn, under normal pressure After heating to 80°C, add 37.7g of calcium hydroxide aqueous solution with a mass fraction of 20.0%, stir and react at 90°C for 4 hours, then gradually raise the temperature to 160°C, stir for 1.6h, dehydrate until the mass content of water is 0.02%, and cool to 60°C;

[0046] B. Add 2.2g of sulfur-phosphorous primary-secondary alcohol base zinc salt in the reaction kettle, 4.0g of sulfurized isobutylene, 1.0g of benzotriazole, 0.2g of benzotriazole derivative T551, after fully stirring, pass through homogenizer homogenization, Then degas...

Embodiment 2

[0048] The preparation method of composite lithium-calcium grease comprises the following steps:

[0049] A. Use 100# industrial grade white oil (40°C kinematic viscosity of 100mm 2 ·s -1 ) to a cone penetration of 460, adopt high-speed centrifugation, filter to remove mechanical impurities, weigh 400.0g and put it into the reaction kettle, add 32.0g of 12-hydroxystearic acid and 8.0g of stearic acid to the reaction kettle in turn, under normal pressure After heating to 80°C, add 100.0g of calcium hydroxide aqueous solution with a mass fraction of 10.0%, stir and react at 90°C for 4 hours, then gradually raise the temperature to 160°C, stir for 2 hours, dehydrate until the mass content of water is 0.03%, and cool to Below 58°C;

[0050] B. Add 3.0g of sulfur-phosphorous primary-secondary alcohol base zinc salt in the reactor, 8.0g of sulfurized isobutylene, 1.2g of benzotriazole, 0.4g of benzotriazole derivative T551, after fully stirring, pass through homogenizer homogeniza...

Embodiment 3

[0052] The preparation method of composite lithium-calcium grease comprises the following steps:

[0053] A. Use SN150# base oil (40°C kinematic viscosity of 30mm 2 ·s -1 ) to a cone penetration of 430, adopt high-speed centrifugation, filter to remove mechanical impurities, weigh 400.0g and put it into the reaction kettle, add 16.0g of 12-hydroxystearic acid and 4.0g of stearic acid to the reaction kettle in turn, under normal pressure After heating to 80°C, add 16.7g of calcium hydroxide aqueous solution with a mass fraction of 30.0%, stir and react at 90°C for 4 hours, then gradually raise the temperature to 160°C, stir for 2 hours, dehydrate until the mass content of water is 0.02%, and cool to 40°C;

[0054] B. Add 2.5g of sulfur phosphorus primary and secondary alcohol zinc salts in the reactor, 6.0g of sulfurized isobutylene, 1.0g of benzotriazole, 0.3g of benzotriazole derivative T551, after fully stirring, pass through homogenizer homogenization, Then degas, that i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| cone penetration | aaaaa | aaaaa |

| cone penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com