Preparation method of microemulsified cutting fluid

A cutting fluid and micro-emulsion technology, applied in the field of cutting fluid processing, can solve problems such as the inability to meet production requirements, and achieve the effects of saving catalyst costs, improving easy oxidation, and reducing contact opportunities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

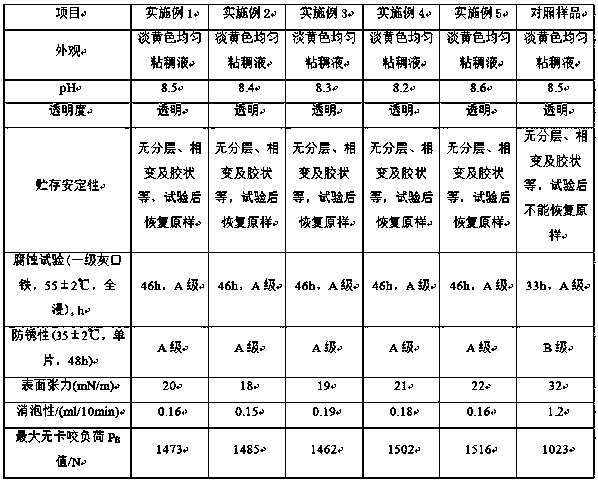

Examples

Embodiment 1

[0034] Preparation of phosphotungstic acid-benzothiazole ionic liquid graft copolymer: Take 35 parts of phosphotungstic acid and double-distilled water into a round bottom flask and stir it magnetically, while heating to 82°C to dissolve completely, and then lower the temperature to 40°C ℃, add 18 parts of 1mol / L nitric acid solution, then 18 parts of initiator cerium ammonium nitrate and 45 parts of benzothiazole, and react in nitrogen atmosphere for 4 hours; wash the obtained product repeatedly with methanol, and then mix the product with an appropriate amount of twice distilled water Add it into a flask and stir it magnetically, then heat it to 82°C to dissolve it completely, then add 40 parts of a sulfuric acid solution with a mass fraction of 98% to react at a constant temperature for 22 hours, then wash the residue with ethyl acetate, and dry it in vacuum at 40°C for 12 hours to obtain Phosphotungstic acid-benzothiazole ionic liquid graft copolymer;

[0035] Preparation ...

Embodiment 2

[0040] Preparation of phosphotungstic acid-benzothiazole ionic liquid graft copolymer: Take 30 parts of phosphotungstic acid and double-distilled water into a round bottom flask and stir it magnetically, while heating to 88°C to completely dissolve it, and then lower the temperature to 36°C ℃, add 16 parts of 1mol / L nitric acid solution, then 12 parts of initiator cerium ammonium nitrate and 30 parts of benzothiazole, and react in nitrogen atmosphere for 4 hours; wash the obtained product repeatedly with methanol, and then mix the product with an appropriate amount of twice distilled water Add it into a flask and stir it magnetically, then heat it to 88°C to dissolve it completely, then add 30 parts of sulfuric acid solution with a mass fraction of 98% to react at a constant temperature for 20 hours, then wash the residue with ethyl acetate, and dry it in vacuum at 40°C for 12 hours to obtain Phosphotungstic acid-benzothiazole ionic liquid graft copolymer;

[0041] Preparation...

Embodiment 3

[0046] Preparation of phosphotungstic acid-benzothiazole ionic liquid graft copolymer: Take 40 parts of phosphotungstic acid and double-distilled water into a round-bottomed flask and stir it magnetically, while heating to 85°C to dissolve it completely, and then lower the temperature to 35°C ℃, add 19 parts of 1mol / L nitric acid solution, then 14 parts of initiator cerium ammonium nitrate and 40 parts of benzothiazole, and react in a nitrogen atmosphere for 4 hours; wash the obtained product repeatedly with methanol, and then mix the product with an appropriate amount of twice distilled water Add it into a flask and stir it magnetically, then heat it to 85°C to dissolve it completely, then add 45 parts of a sulfuric acid solution with a mass fraction of 98% to react at a constant temperature for 24 hours, then wash the residue with ethyl acetate and dry it in vacuum at 40°C for 12 hours to obtain Phosphotungstic acid-benzothiazole ionic liquid graft copolymer;

[0047] Prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com