Copper electroplating solution applied to dry etching method copper interconnection Damascus and copper electroplating method thereof

A technology of copper electroplating and dry etching, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of copper instability, damage to the silicon layer and the dielectric layer, etc., to achieve good dispersion, shorten the process flow, and stabilize the plating solution. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

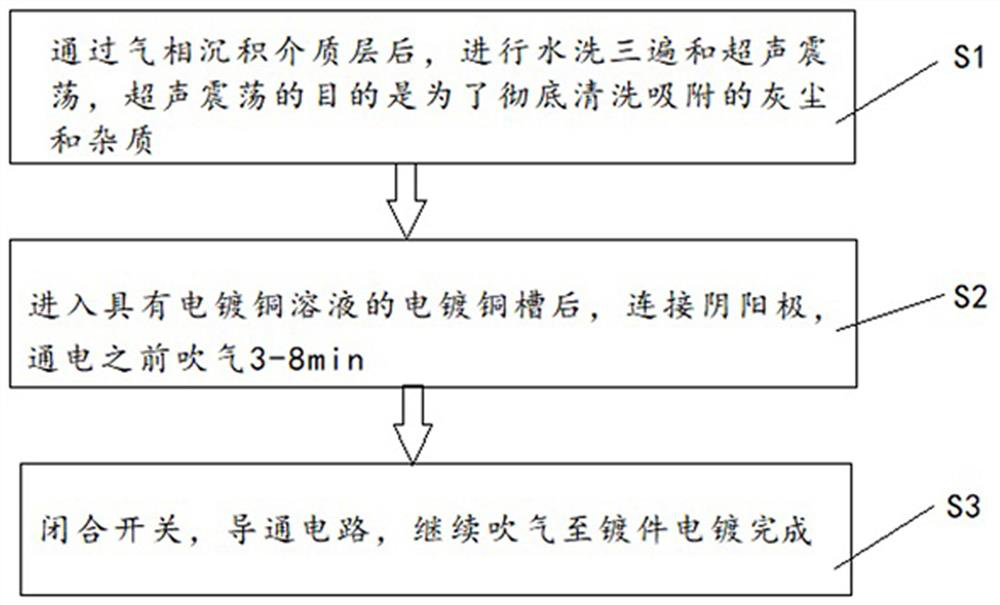

Method used

Image

Examples

Embodiment 1

[0085] A copper electroplating solution applied to copper interconnection damascene by dry etching method, calculated per liter of bath solution:

[0087] Dibenzopyrrolo[1,2-a][1,8]phthalazine 30mg / L

[0088] Polypyrrole 30mg / L

[0089] 2-Amino-(4-azaindolyl)-4-methylthiazoline 30mg / L

[0090] Cerium sulfate 10mg / L

[0091] Chlorogenic acid 5g / L

[0092] Manganese sulfate 30mg / L

[0093] Lead acetate 15mg / L

[0094] Sodium sulfite 0.3g / L

[0095] The balance is pure water

[0096] pH 6.5

[0097] Operating temperature 30°C

[0098] Time 40min

[0099] The current density is 2.5A / dm 2

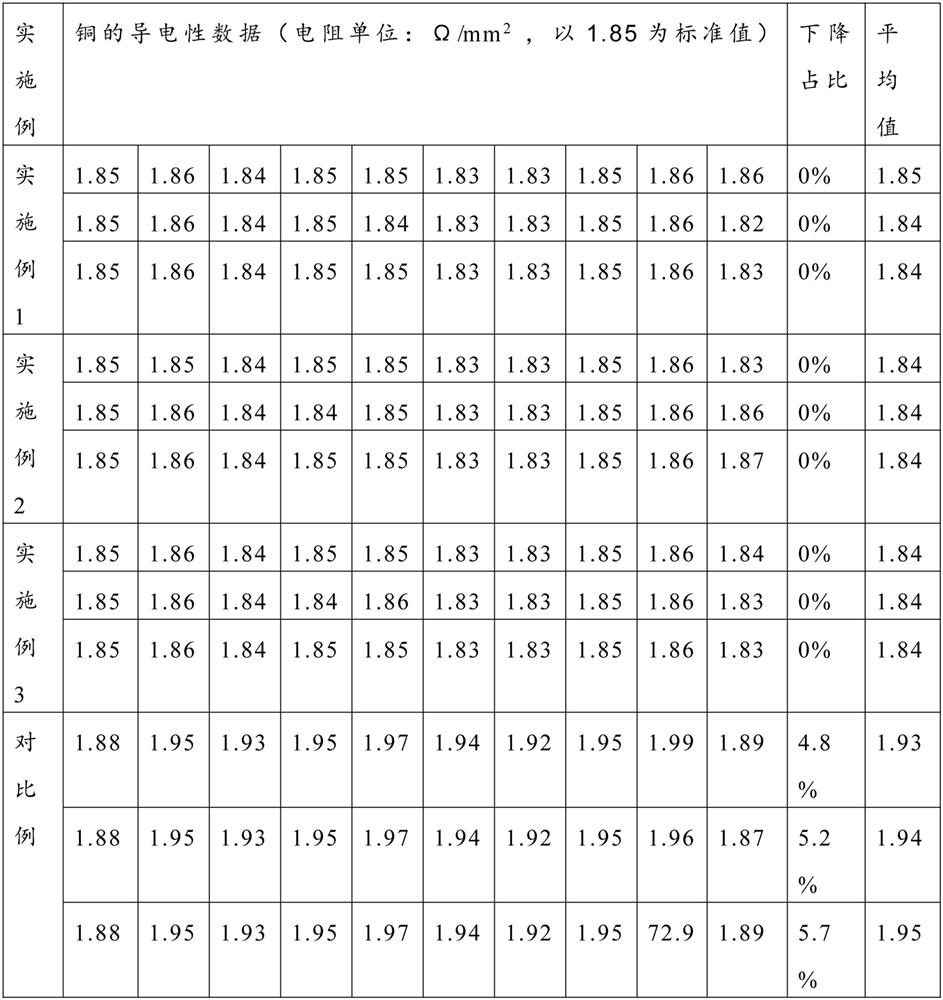

[0100] The judging criteria are as follows

[0101] A. The uniformity of the electroplated copper layer is a means that the appearance is bright and there is no color difference. Take three groups of data from the five-point method in the middle of the four sides, and the difference between each group is no more than 5% compared with the average value; ...

Embodiment 2

[0106] A copper electroplating solution applied to copper interconnection damascene by dry etching method, calculated per liter of bath solution:

[0107] Copper sulfate 10g / L

[0108] Dibenzopyrrolo[1,2-a][1,8]phthalazine 20mg / L

[0109] Polypyrrole 20mg / L

[0110] 2-Amino-(4-azaindolyl)-4-methylthiazoline 20mg / L

[0111] Cerium sulfate 10mg / L

[0112] Chlorogenic acid 5g / L

[0113] Manganese sulfate 15mg / L

[0114] Lead acetate 10mg / L

[0115] Sodium sulfite 0.3g / L

[0116] The balance is pure water

[0117] pH 7

[0118] Operating temperature 30°C

[0119] Time 40min

[0120] The current density is 2.5A / dm 2

Embodiment 3

[0122] A copper electroplating solution applied to copper interconnection damascene by dry etching method, calculated per liter of bath solution:

[0123] Copper sulfate 10g / L

[0124] Dibenzopyrrolo[1,2-a][1,8]phthalazine 10mg / L

[0125] Polypyrrole 10mg / L

[0126] 2-Amino-(4-azaindolyl)-4-methylthiazoline 10mg / L

[0127] Cerium sulfate 10mg / L

[0128] Chlorogenic acid 5g / L

[0129] Manganese sulfate 18mg / L

[0130] Lead acetate 12mg / L

[0131] Sodium sulfite 0.3g / L

[0132] The balance is pure water

[0133] pH 7.5

[0134] Operating temperature 30°C

[0135] Time 40min

[0136] The current density is 2.5A / dm 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com