Solid lubricator

A solid lubrication and lubricator technology, which is applied in the direction of engine lubrication, engine components, elevators, etc., can solve the problems of accelerating steel pipe fatigue cracks, oil wedges, and pollution, and achieves wide operating temperature range, outstanding wear reduction effect, Excellent extreme pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

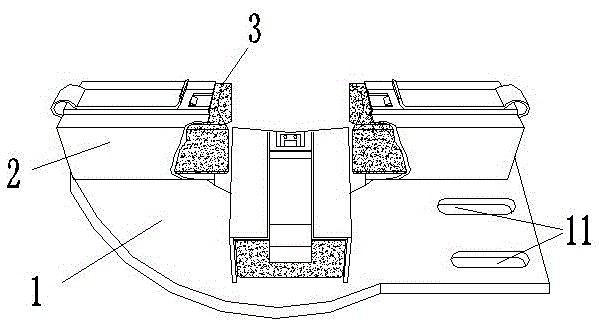

[0023] Such as figure 1 , Figure 4 , Figure 5 , Image 6 A solid lubricator shown includes a fixed seat 1, the fixed seat 1 is a semi-annular fixed seat, and a first solid lubricating device and a second solid lubricating device are respectively installed on the semi-annular fixed seat. The first solid lubricating device and the second solid lubricating device are located on the same horizontal line, a third solid lubricating device is installed on the semi-annular fixing seat between the first solid lubricating device and the second solid lubricating device, and the first solid lubricating device The three solid lubricating devices are vertically installed with the first solid lubricating device and the second solid lubricating device respectively. When the lubricated lifting guide rail is cylindrical, the semi-circular fixing seat can be used to lubricate the cylindrical lifting guide rail.

[0024] The solid lubricating device includes a solid lubricating block storag...

Embodiment 2

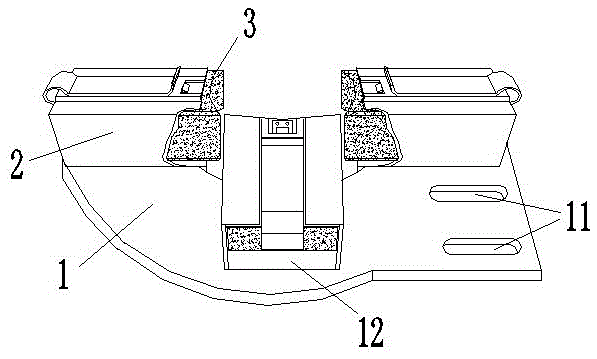

[0033] Such as figure 2 , Figure 4 , Figure 5 , Image 6 A solid lubricator shown includes a fixed seat 1, the fixed seat 1 is a semi-annular fixed seat, and a first solid lubricating device and a second solid lubricating device are respectively installed on the semi-annular fixed seat. The first solid lubricating device and the second solid lubricating device are located on the same horizontal line, a third solid lubricating device is installed on the semi-annular fixing seat between the first solid lubricating device and the second solid lubricating device, and the first solid lubricating device The three solid lubricating devices are vertically installed with the first solid lubricating device and the second solid lubricating device respectively. When the lubricated lifting guide rail is cylindrical, the semi-circular fixing seat can be used to lubricate the cylindrical lifting guide rail.

[0034] A pad 12 is installed between the third solid lubricating device and ...

Embodiment 3

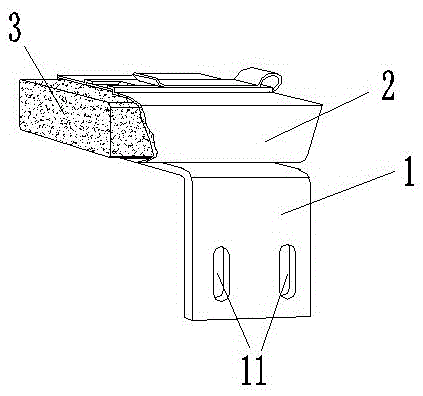

[0044] Such as image 3 , Figure 4 , Figure 5 , Image 6 A solid lubricator shown includes a fixed seat 1, which is a right-angled fixed seat, and a solid lubricating device is installed on the right-angled fixed seat. When the lubricated lifting guide rail is square, the right-angled fixing seat can be used to lubricate the cylindrical lifting guide rail.

[0045]The solid lubricating device includes a solid lubricating block storage box 2, the solid lubricating block storage box 2 is installed on the fixed seat 1, a solid lubricating block 3 is installed in the solid lubricating block storage box 2, and the solid lubricating block is stored A solid lubricating block propelling device is installed on the box 2, and the solid lubricating block propelling device is connected with the solid lubricating block 3 in conflict. The lubricating contact surface of the solid lubricating block 3 can be arranged in an arc shape, and can be close to the guide rail to improve the lubr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com