Worm and gear oil composition and preparation method thereof

A technology of oil composition and worm gear, which is applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of reducing gear pitting and copper worm gear corrosion, and achieves the reduction of energy loss, low pour point, and easy start-up at low temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the worm gear oil composition provided by the present invention includes: according to the viscosity grade of the composition, one or more polyether oils are added in proportion to a container with stirring, and then the above additive components are added in proportion, and then Stir at 20-60°C until uniform and transparent.

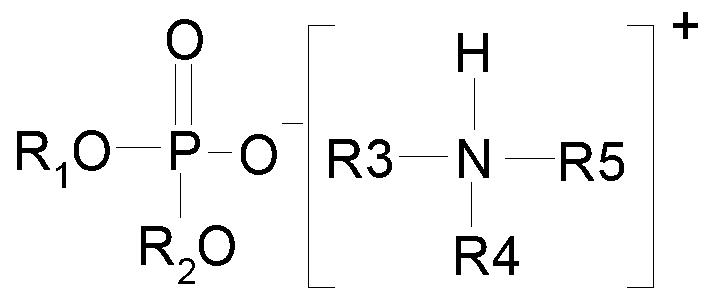

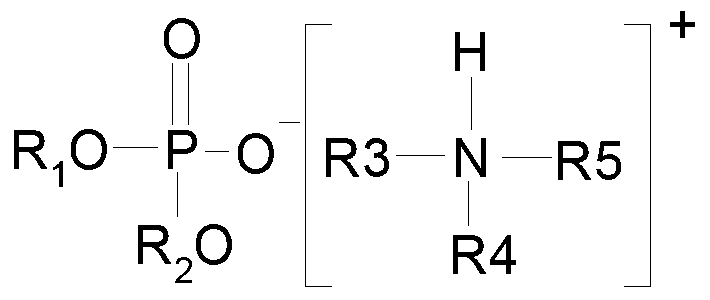

[0036] In the worm gear and worm oil composition provided by the present invention, the extreme pressure and antiwear agent of B component contained does not contain sulfur element, will not cause corrosion to the copper worm gear, and at the same time has better performance than the extreme pressure and antiwear agent containing sulfur. Excellent extreme pressure performance prevents the tooth surface from being scratched, sintered, worn, etc. In addition, component B can also reduce the friction coefficient of lubricating oil, greatly reducing the energy loss caused by transmission friction. It is suitable for copper-c...

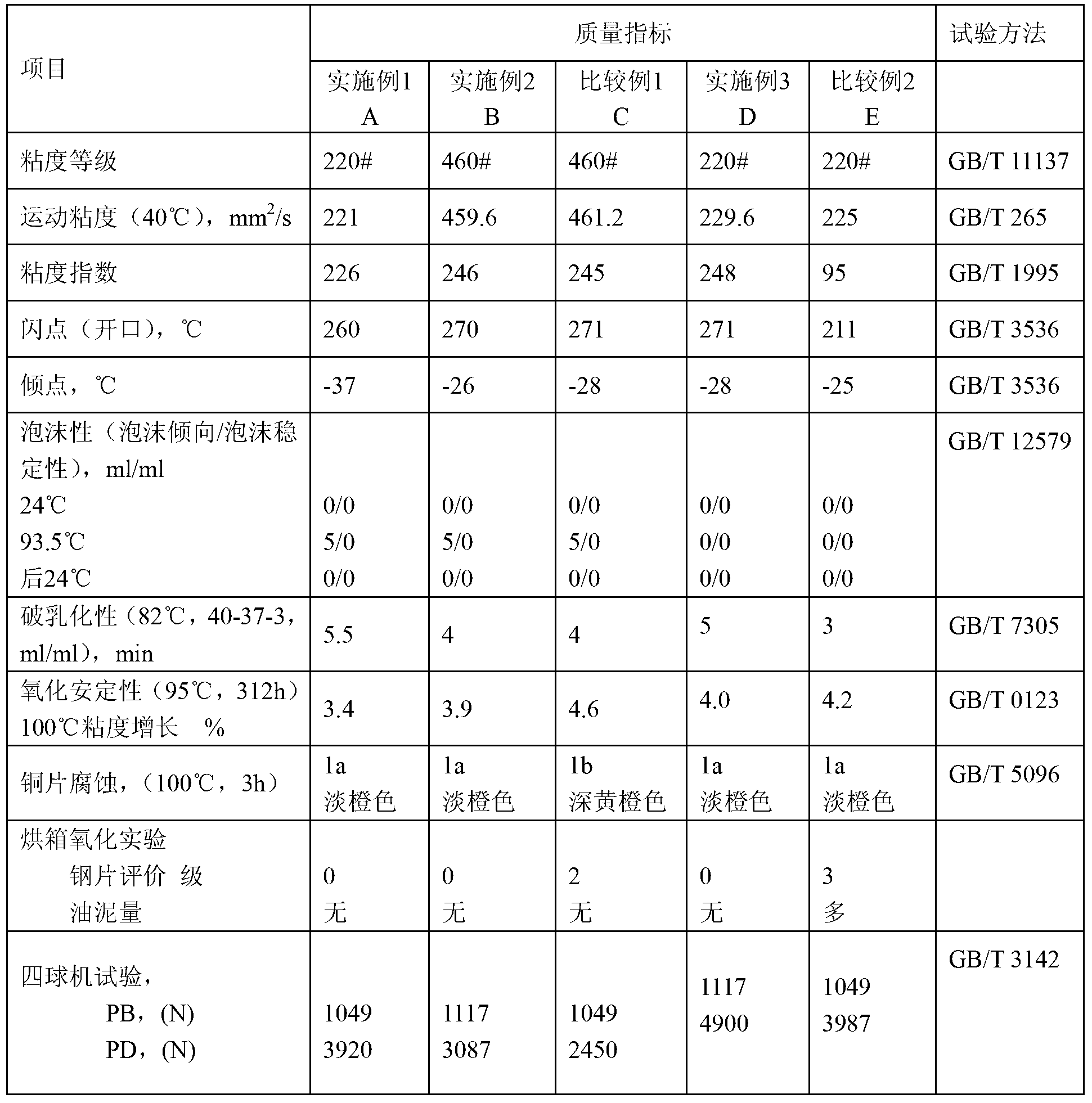

Embodiment 1

[0042] Add 100 parts by weight of water-insoluble polyether oil base oil Emkarox VG222 (Croda Chemical Company, Inc) into a stainless steel mixing kettle with agitator, keep the temperature of the kettle at 40°C, and then add 1 part by weight as extreme pressure and anti-wear The compound Vanlube692 (R.T.Vanderbilt Company, Inc, the same below) of dibutyl phosphate and 4-tetrapropylene aniline as an agent, 0.2 parts by weight of benzotriazole octadecylamine salt T406 as an oily agent or a friction modifier (Jinzhou Kangtai Lubricating Oil Additive Co., Ltd., the same below), 0.5 parts by weight of butyloctyldiphenylamine antioxidant, 0.1 part by weight of metal deactivator benzotriazole derivative T551 (Jinzhou Kangtai Lubricating Oil Additive Co., Ltd., the same below) ), 0.002 parts by weight of methyl silicone oil as an antifoaming agent (Jinzhou Kangtai Lubricating Oil Additive Co., Ltd., the same below), 0.003 parts by weight of demulsifier propylene oxide / ethylene oxide b...

Embodiment 2

[0044] Add 100 parts by weight of water-insoluble polyether oil base oil Emkarox VG462 (Croda Chemical Company, Inc) into a stainless steel mixing kettle with agitator, keep the temperature of the kettle at 30°C, and then add 0.8 parts by weight as extreme pressure and anti-wear Vanlube692, 0.5 parts by weight of tricresyl phosphate as other phosphorus-containing antiwear agents, 0.2 parts by weight of benzotriazole octadecylamine salt T406 as oily agent or friction modifier, 0.5 parts by weight of butyl octyl diphenylamine Antioxidant, 0.1 parts by weight of T551, 0.002 parts by weight of methyl silicone oil as an antifoaming agent, and 0.003 parts by weight of Lubrizol5957 were added to the blending kettle, and stirring was started until the mixture was completely dissolved, uniform and transparent, and the finished worm gear oil B was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com