Special castor-oil-based gear oil for wind power generation

A castor-based, gear oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as short life, environmental pollution, and insufficient performance, and achieve the effect of reducing the number of oil changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

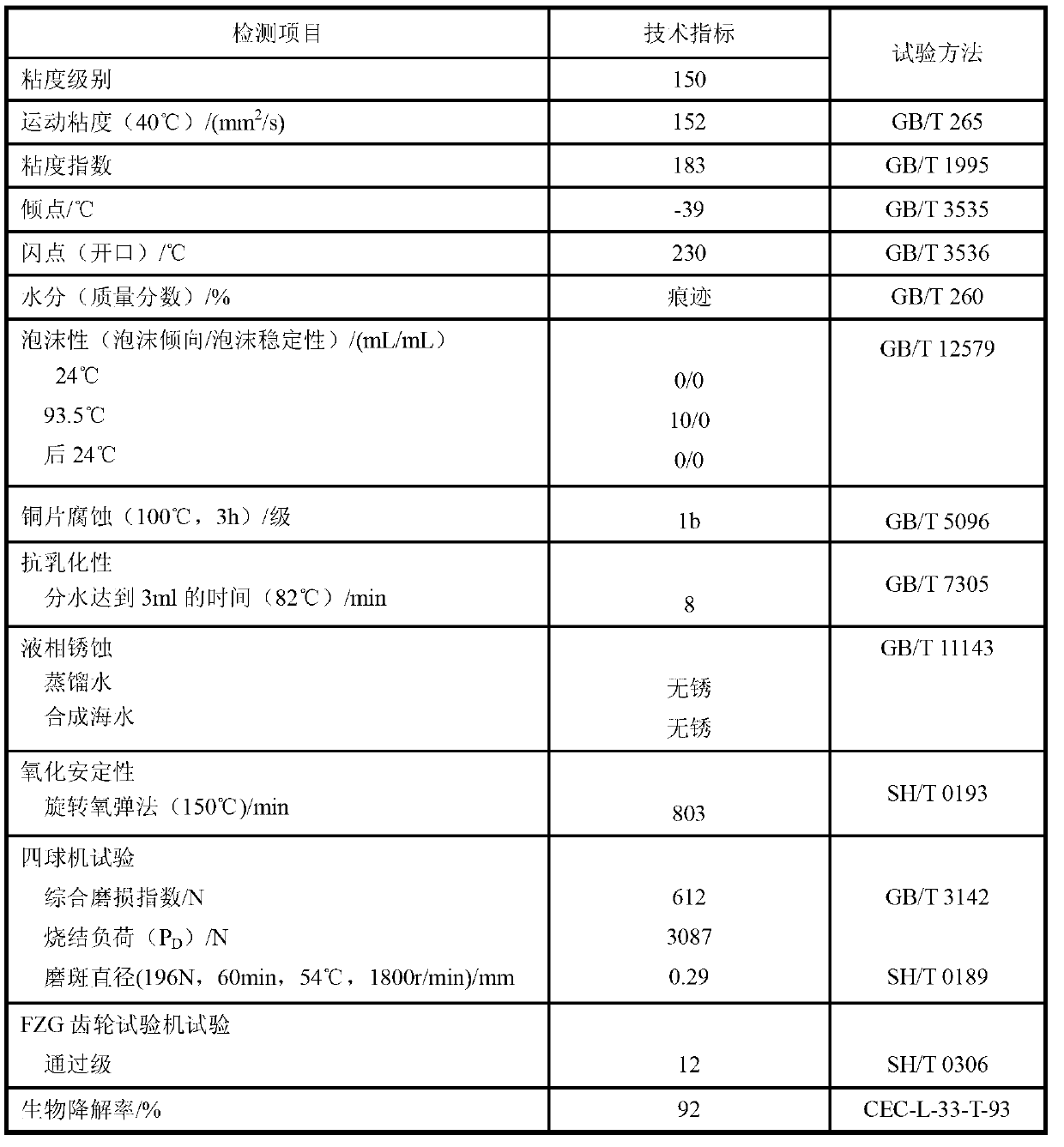

Embodiment 1

[0028]A castor-based gear oil for wind power generation, composed of polyethylene glycol sebacate, diisooctyl sebacate, benzotriazole octadecylamine salt, isobutylene sulfur, phosphate amine salt, thiadiazole Derivatives, 2,6-di-tert-butyl-p-cresol, dialkyldiphenylamine, dibutyldithiocarbamate, condensate of amine and ethylene oxide, neutral barium dinonylnaphthalenesulfonate , silicone oil type antifoaming agent and non-silicon type antifoaming agent, the mass percentage of each component is: polyethylene glycol sebacate 90%, diisooctyl sebacate 7.506%, benzotriazepam 0.1% azole octadecylamine salt, 0.82% sulfurized isobutylene, 0.44% phosphate ester amine salt, 0.05% thiadiazole derivatives, 0.3% 2,6-di-tert-butyl p-cresol, 0.4% dialkyl diphenylamine, 0.25% dibutyl dithiocarbamate, 0.05% condensate of amine and ethylene oxide, 0.05% neutral barium dinonyl naphthalene sulfonate, 0.004% silicone oil type antifoaming agent, non-silicon type antifoaming agent 0.03%.

[0029] P...

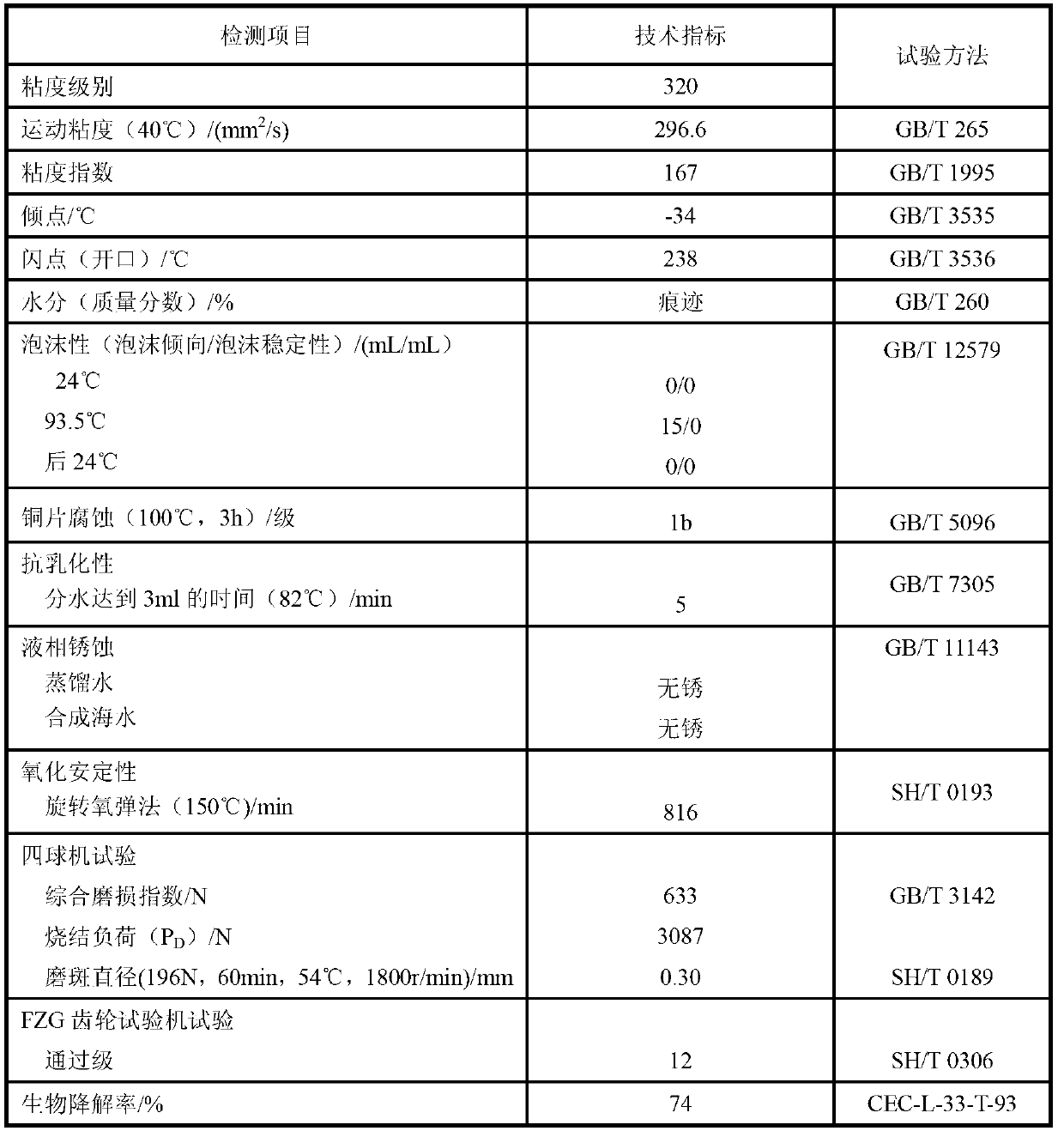

Embodiment 2

[0033] A castor-based gear oil for wind power generation, composed of polyethylene glycol sebacate, polyalpha-olefin, butyl oleate, isobutylene sulfur, phosphate amine salt, thiadiazole derivatives, mixed phenols, dioxane Diphenylamine, dibutyldithiocarbamate, amine and ethylene oxide condensate, dodecenylsuccinate half ester, silicone oil type antifoaming agent and non-silicon type antifoaming agent, The mass percentage of each component is: polyethylene glycol sebacate 78%, polyalphaolefin 19.506%, butyl oleate 0.1%, sulfurized isobutylene 0.82%, phosphate amine salt 0.44%, thiadiazole derivatives 0.05%, mixed phenol 0.3%, dialkyl diphenylamine 0.4%, dibutyl dithiocarbamate 0.25%, amine and ethylene oxide condensate 0.05%, dodecenyl succinic acid half ester 0.05 %, silicone oil type antifoam agent 0.004%, non-silicon type antifoam agent 0.03%.

[0034] Preparation method: add polyethylene glycol sebacate and polyα-olefin in proportion to a blending kettle with a stirrer, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com