Anti-oxidation lubricating oil composition

A lubricating oil composition and lubricating oil technology, applied in the directions of lubricating composition, petroleum industry, additives, etc., can solve the problems of limited amount of additives, insufficient to meet the requirements of use, etc., and achieve the effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

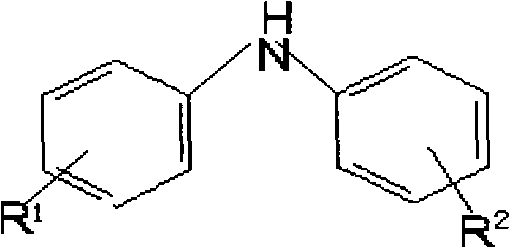

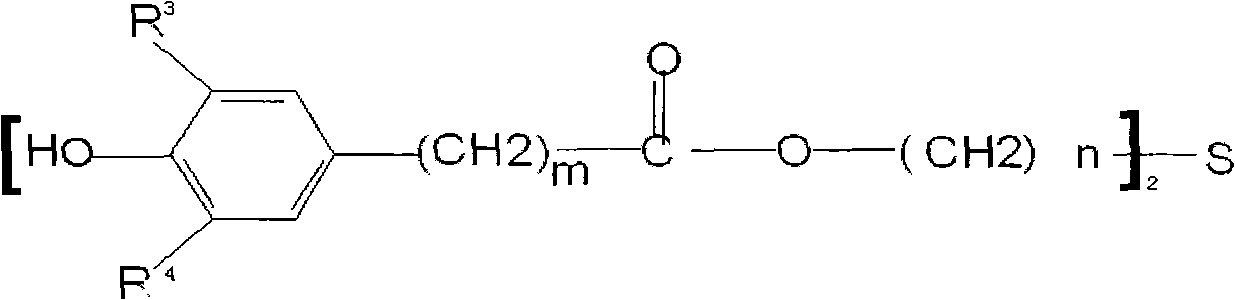

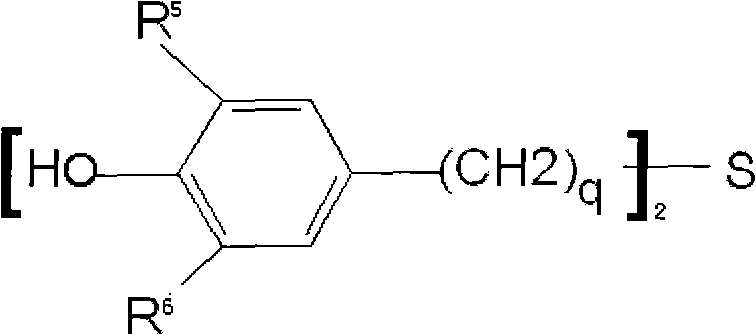

Method used

Image

Examples

Embodiment 1-5

[0036] Examples 1-5 are additive products and main properties of the present invention. Add each component I and component II into a mixing container in proportion, heat at 60-90°C under normal pressure, and stir for 1-2 hours to obtain a uniform transparent light yellow viscous liquid, which is the product of the present invention. The results are shown in Table 1.

[0037] Table 1

[0038] serial number

[0039] Example 5

Embodiment 6

[0041] In this example, the anti-oxidation effect of lubricating oil is evaluated according to the method of rotating oxygen bomb test ASTM D2272. The rotating oxygen bomb test is a rapid screening method and is a commonly used experiment for evaluating the oxidation stability of engine oil and industrial lubricating oil. The test instrument consists of a pressure bomb and an oil bath. The pressure bomb is rotated at 30° with the horizontal plane. The oil bath is kept at a constant temperature of 150°C. 50 grams of test oil, 5 grams of water and a copper ring catalyst are added to the glass together, and oxygenated at room temperature. 620kPa (90psi), put the oxygen bomb into the oil bath, the oxygen pressure rises rapidly and remains constant, record the time when the oxygen pressure drops 170kPa (25psi) from the highest point, as the oil sample oxidation induction period. The oil used in the test was 150N hydrogenated base oil produced by Sinopec Gaoqiao Petrochemical Company...

Embodiment 7

[0046]In the prepared SJ gasoline engine oil 5W / 30 test oil, a dosage of 0.38% of antioxidant and 6.62% of the remaining additives were added, and the thin layer oxidation test (TFOUT) was carried out, and the pressure differential thermal scanning test was carried out. (PDSC), high temperature sediment evaluation test (TEOST) and IIIE simulation test (VIT); among them, thin layer oxidation test (TFOUT) is carried out according to ASTM D2272; PDSC set temperature is 220 ℃; IIIE simulation test (VIT) for viscosity growth Investigate that the test conditions are 160°C, the oxygen flow rate is 5L / h, and calculate the time when the viscosity growth rate is 375%. The specific results are shown in Table 3.

[0047] table 3

[0048]

[0049] It can be seen from Table 3 that at a high temperature of 220°C, the composite antioxidant effectively improves the oxidation induction period (PDSC) of the oil, and the oxidation induction period of the oil in the comparative example is usua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com