Formula of special lubricating oil for engineering machinery and production process of lubricating oil

A technology for construction machinery and lubricating oil, which is applied in the direction of lubricating composition and petroleum industry, etc. It can solve the problems of long-term operation of construction machinery, complex working conditions, heavy heat load, frequent oil changes, failure to prevent engine wear, and general oxidation stability. To achieve good oxidation stability and thermal stability, control oil viscosity growth, and control piston deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The raw materials in this example include base oil and additives. The base oil includes hydrogenated mineral base oil 650SN and bright stock 150BS; the additive includes complex agent H8744B, viscosity index improver OCP, pour point depressant 1-248 and anti Foaming agent T901; the mass percentage of each component in the raw material is: hydrogenated mineral base oil 650SN is 72.5%, bright stock 150BS is 5%, compounding agent H8744B is 13%, viscosity index improver agent OCP is 9%, pour point depressant Agent 1-248 is 0.5%, antifoaming agent T901 is 0.001%.

[0018] The composite agent H8744B of the present invention is a high-performance multi-purpose engine oil composite additive. Its main components are calcium, molybdenum, nitrogen, and zinc. It applies a new type of ashless dispersant and all-calcium-based detergent. Excellent cleaning and dispersing properties, effectively reducing carbon deposits, excellent lubricity and extreme pressure resistance, greatly red...

Embodiment 2

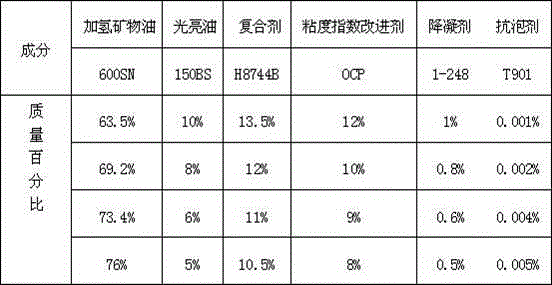

[0030] The present invention can adjust the mass percentages among the components according to actual needs, see Table 1.

[0031] Table 1 The mass percent of each composition of other embodiment of the present invention

[0032]

[0033] The production process of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com