Lubricating oil composition for industrial machinery and equipment

A technology of lubricating oil composition and industrial machinery, which is applied in the direction of lubricating composition, petroleum industry, additives, etc., can solve the problems of sludge generation and friction coefficient increase of sliding parts, etc., and achieve excellent sludge resistance and anti-stick-slip performance Excellent wear and friction properties, sludge resistance and extreme pressure properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0466] The present invention will be described in more detail below by way of examples. In addition, the gear oil, the lubricating oil for a paper machine, the lubricating oil for a sliding guide surface, and the hydraulic oil which are specific embodiments of the lubricating composition of the present invention will be described sequentially through respective examples.

[0467] [Gear Oil Composition-1]

[0468] This example relates to an embodiment in which a gear oil is obtained by blending the above-mentioned base oil with the component (C-1), the component (C-2), or a mixture thereof.

[0469] The types and amounts of the base oils tested and the additives added therein are shown below. In addition, the test method performed on each lubricating oil composition compounded is similarly shown below. The obtained test results are shown in Tables 1 to 3.

[0470] (IAE oil temperature)

[0471] According to the IAE gear test stipulated in IP166 / 77 (92), the gear box is oper...

Embodiment 6~8

[0887] In Examples 6 to 8, lubricating compositions having the compositions shown in Table 4 were prepared using the above-mentioned base oil, additives, and the following oily improvers.

[0888] (D) Ester oiliness improver

[0889] D1: Esters of sorbitan and oleic acid (25mol% sorbitan monooleate, 40mol% sorbitan dioleate, 30mol% sorbitan trioleate, Oleate 5mol%)

[0890] D2: Triesters of mixed fatty acids of glycerol, acetic acid and fatty acids with 16 to 20 carbon atoms (fatty acid composition: 66 mol% of acetic acid, 30 mol% of straight-chain saturated fatty acids with 16 to 20 carbon atoms, 18 carbon atoms Straight chain unsaturated fatty acid 4mol%)

[0891] D3: Esters of glycerin and branched saturated fatty acids with 16 to 20 carbon atoms (monoglyceride 25 mol%, diglyceride 75 mol%, triglyceride 0 mol%).

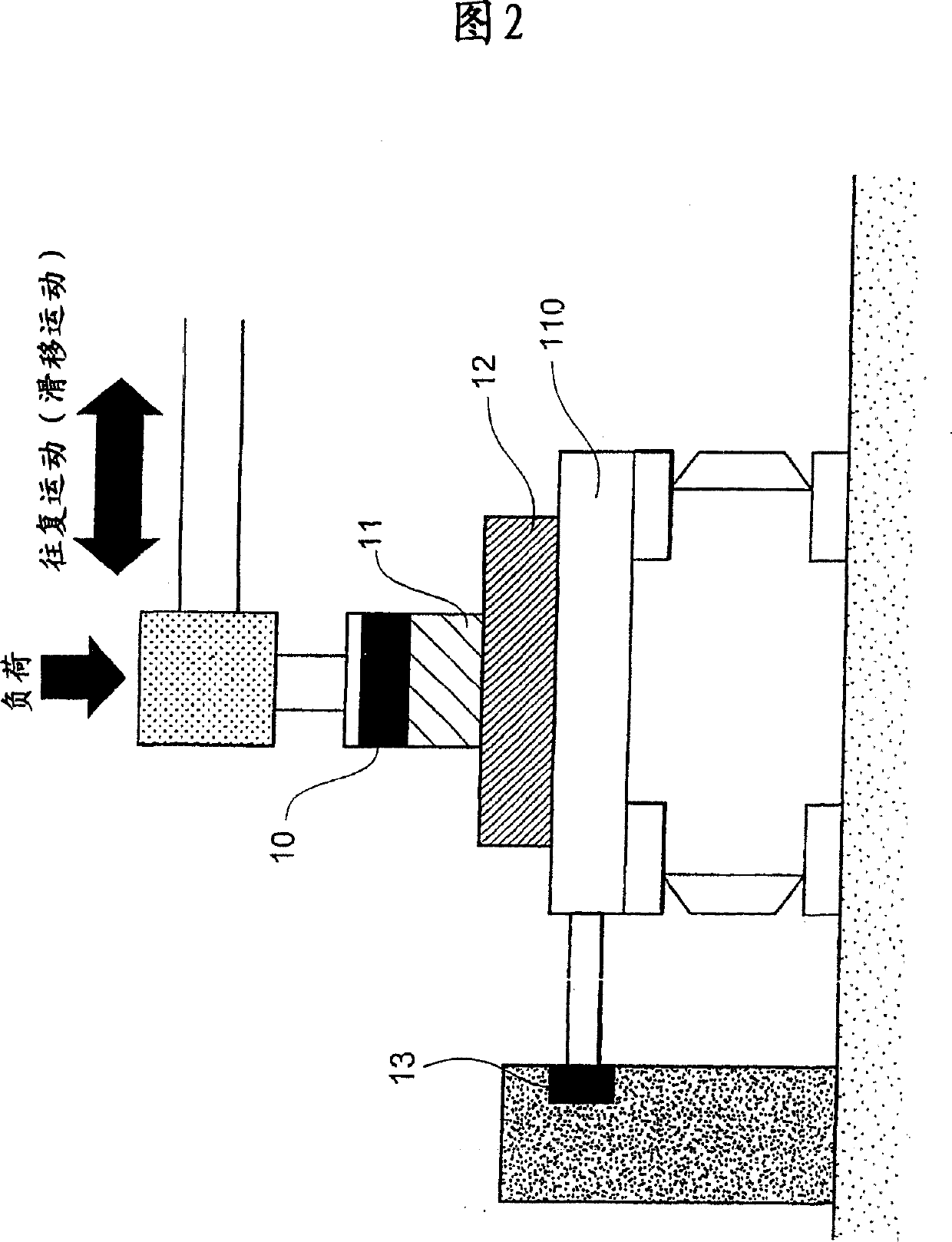

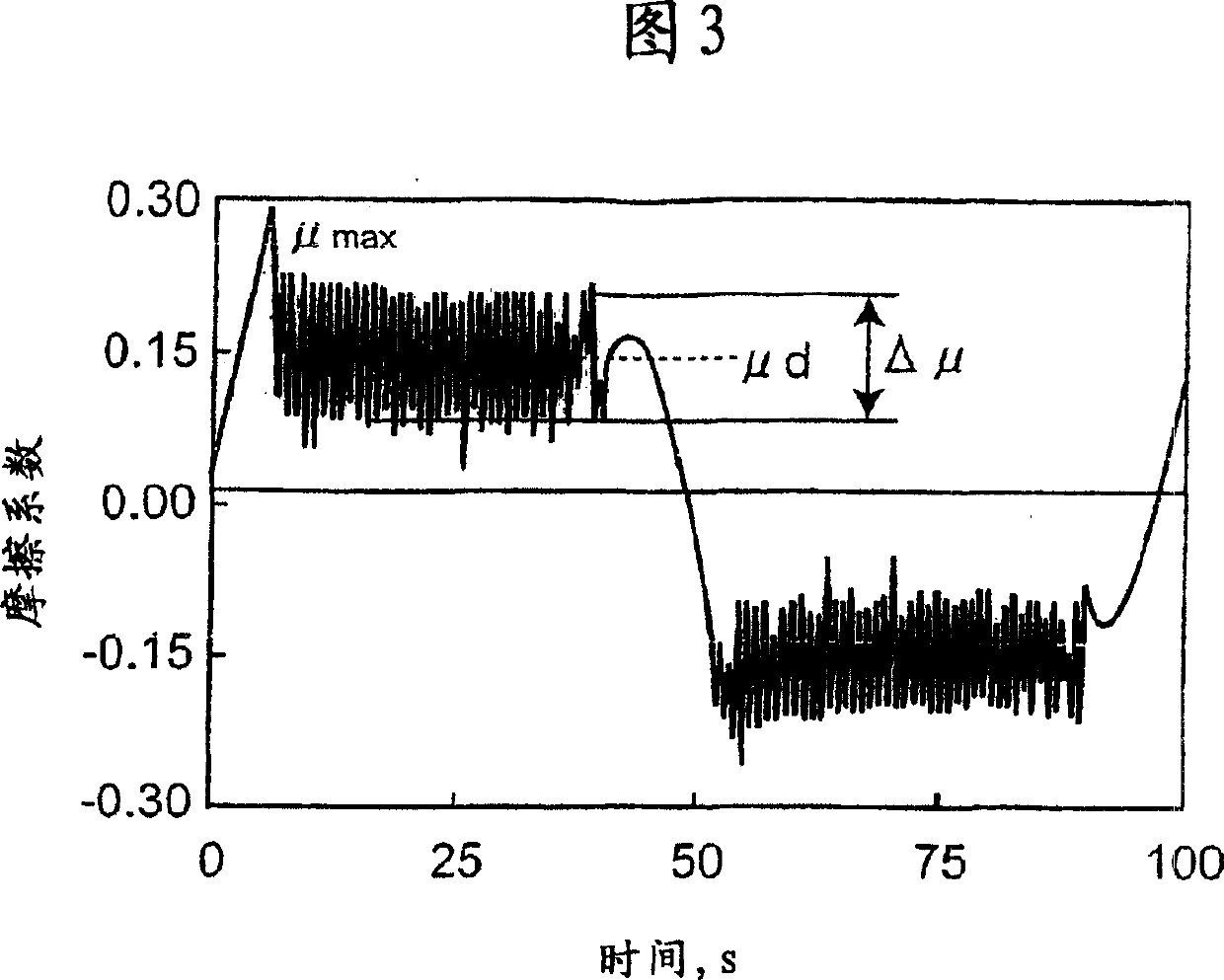

[0892] Next, for each of the lubricating oil compositions obtained in Examples 6 to 8, a thermal stability test, an SRV (micro-reciprocating dynamic friction) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com