Biodegradable industrial gear oil composition

An industrial gear oil, biodegradation technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of affecting the ecological environment and ecological balance, polluting land rivers and lakes, poor biodegradability, etc., and achieve excellent sealing material compatibility , high biodegradation rate, good low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

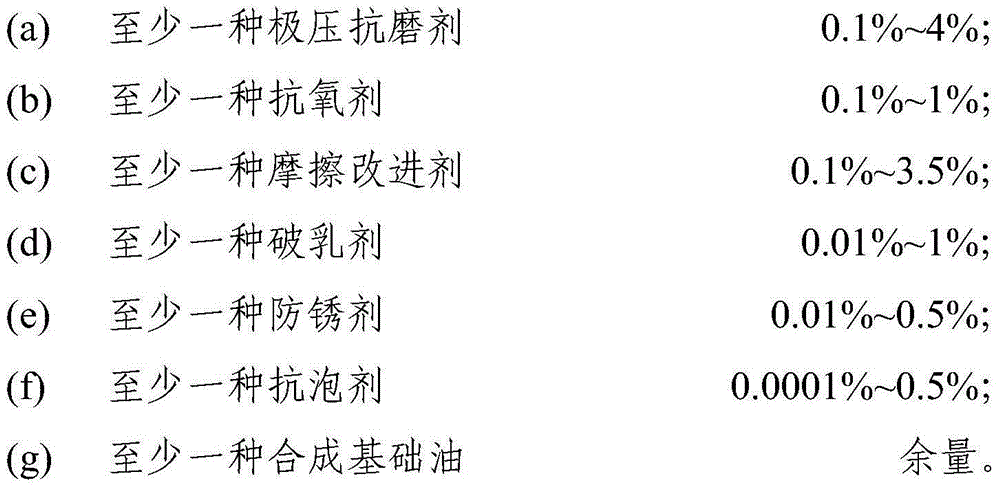

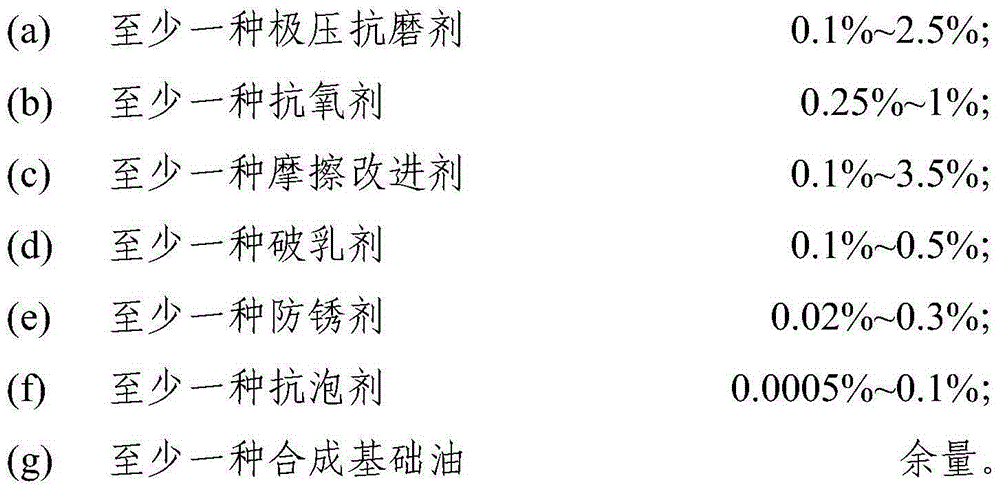

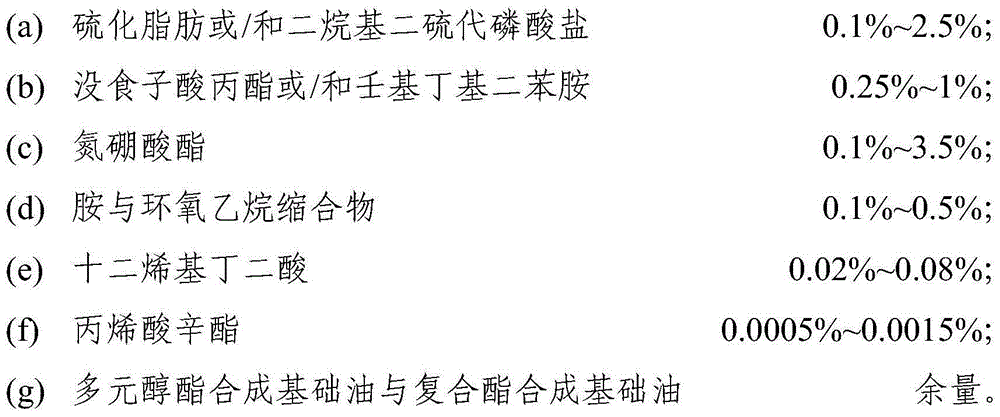

[0031] The biodegradable industrial gear oil composition of the present invention can be formulated as an industrial gear oil with a viscosity grade of ISOVG68-1000 as required. According to the ISO viscosity classification of industrial liquid lubricants, the examples of biodegradable industrial gear oil compositions with ISOVG220 and ISOVG320 viscosity grades are determined. Examples 1 to 3 are ISOVG220 viscosity grades, and Examples 4 and 5 are ISOVG320 viscosity grades. Grade, the specific components of the composition are shown in Table 1.

[0032] Table 1: Composition composition (unit: % by mass)

[0033]

Example 1

Example 2

Example 3

Example 4

Example 5

sulfurized fat

0.1

2.5

0.5

dialkyldithiophosphate

2.45

1.7

2

0.25

0.85

0.4

Nonylbutyldiphenylamine

0.5

0.8

0.6

nitrogen borate

3.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com