Polyester hot-melt adhesive and coating method thereof

A technology of polyester hot-melt adhesives and adhesives, applied in the direction of adhesives, adhesive types, chemical instruments and methods, etc., can solve problems such as adhesive force attenuation, achieve small adhesive force attenuation, fast bonding, and economic benefits high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

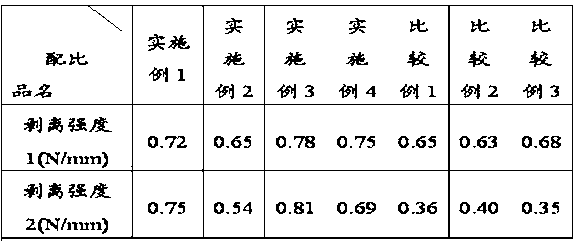

Embodiment 1

[0031] Example 1, a polyester hot-melt adhesive, comprising 80 kg of polyester resin GM420K01, 14 kg of bisphenol A epoxy resin, 5 kg of 1,6-hexamethylene diisocyanate and 1 kg of dicyandiamide.

Embodiment 2

[0032] Embodiment 2, a polyester hot-melt adhesive, comprising polyester resin ES320 80kg, 3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexyl carboxylate 12kg and 1,6-hexane Diisocyanate 8kg.

Embodiment 3

[0033] Embodiment 3, a polyester hot-melt adhesive, comprising polyester resin JCC-3110 80kg, 3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexyl carboxylate 14kg and 1,6 - Hexamethylene diisocyanate 5 kg and dicyandiamide 1 kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com