Co-N-C@RGO composite material, preparation method and application to modification of lithium-sulfur battery diaphragms

A technology of composite materials and diaphragms, applied in the direction of lithium batteries, battery pack parts, non-aqueous electrolyte batteries, etc., can solve problems such as unsatisfactory effects, polysulfide chemical adsorption, etc., to improve conductivity and specific surface area, and improve porosity Structure, the effect of excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

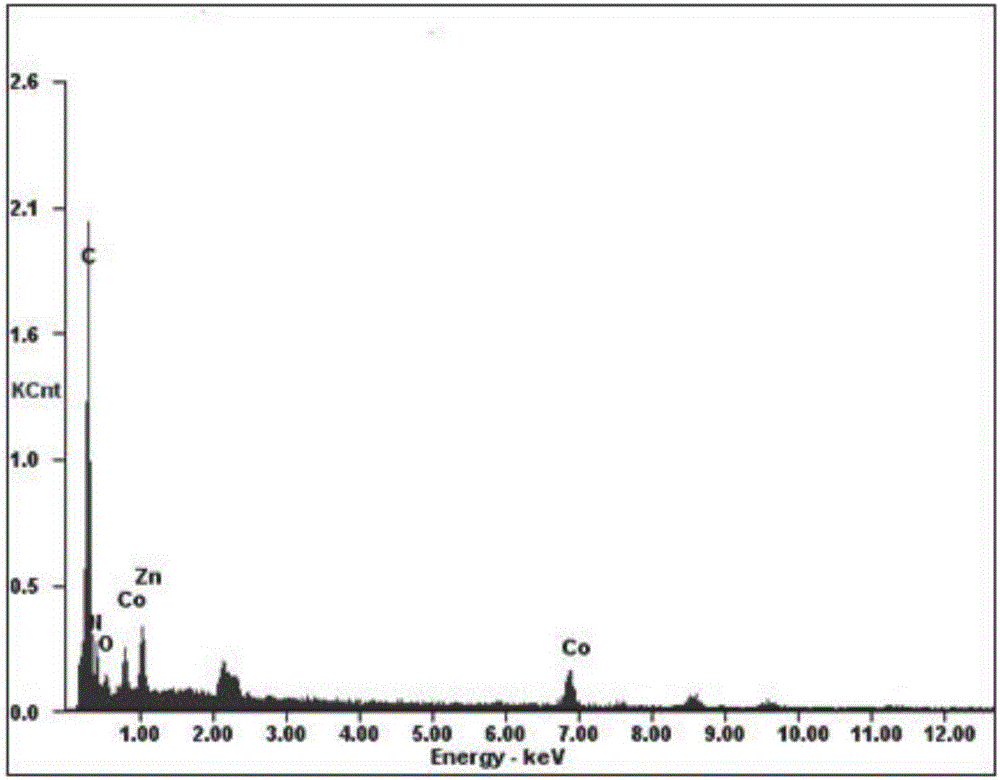

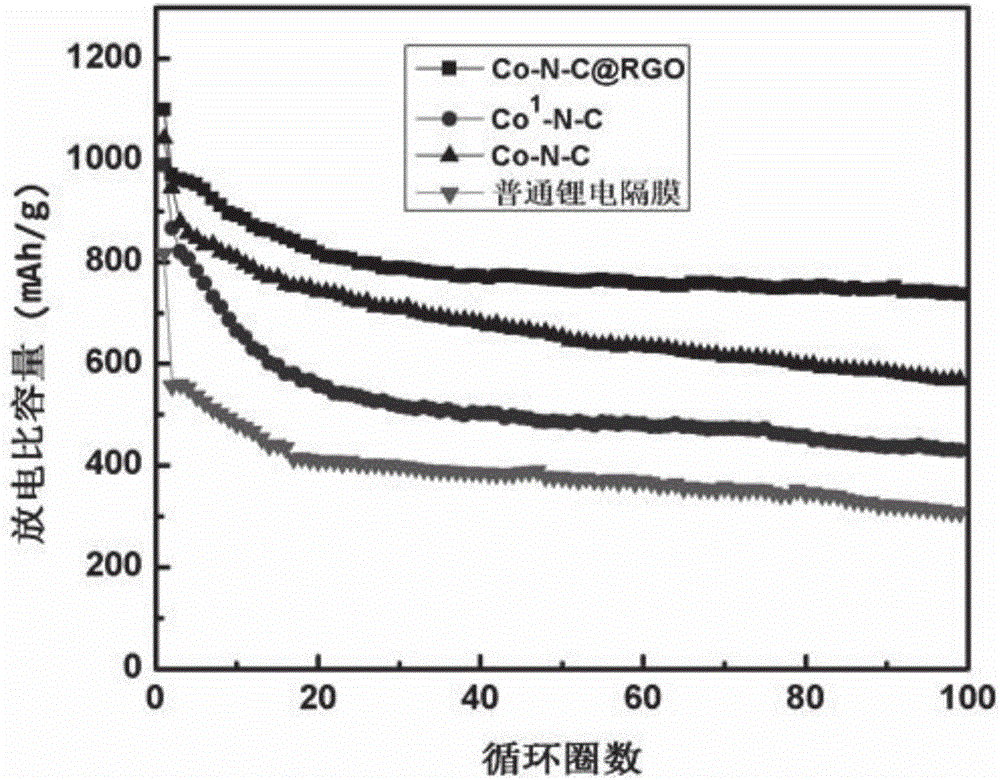

[0107] 1.487g of zinc nitrate hexahydrate and 1.455g of cobalt nitrate hexahydrate were dissolved in 50ml of methanol to obtain solution A; 3.284g of 2-methylimidazole was dissolved in 50ml of methanol, and then 0.16g of commercial graphene was ultrasonically dispersed to obtain Solution B, pour solution A into solution B, mechanically stir at room temperature for 1 hour, then let it stand for half a day, vacuum filter and dry the obtained solid, which is zinc, cobalt-bimetallic organic framework@graphene precursor; will get The precursor was calcined under an argon atmosphere at 950°C for 2h, and the heating rate was 3°C / min; the calcined product was treated with 1mol / L dilute hydrochloric acid for 3 times and then washed with deionized water until neutral (PH=7), 60 After drying at ℃ for 12 h, a cobalt / nitrogen double-doped porous carbon@graphene (Co-N-C@RGO) composite was obtained. The specific surface area of the obtained material is 900-1000m 2 / g, wherein the content ...

Embodiment 2

[0114] 1.487g of zinc nitrate hexahydrate and 1.455g of cobalt nitrate hexahydrate were dissolved in 50ml of methanol to obtain solution A; 2.463g of 2-methylimidazole was dissolved in 50ml of methanol, and then 0.16g of commercial graphene was ultrasonically dispersed to obtain Solution B, pour solution A into solution B, mechanically stir at room temperature for 1 hour, then let it stand for half a day, vacuum filter and dry the solid obtained as zinc, cobalt-bimetallic organic framework @ graphene precursor; will get The precursor was calcined under an argon atmosphere at 950°C for 2h, and the heating rate was 3°C / min; the calcined product was treated with 1mol / L dilute hydrochloric acid for 3 times and then washed with deionized water until neutral (PH=7), 60 After drying at ℃ for 12 h, a cobalt / nitrogen double-doped porous carbon@graphene (Co-N-C@RGO) composite was obtained. The specific surface area of the obtained material is 800-900m 2 / g, wherein the content of Co ...

Embodiment 3

[0118] 1.487g of zinc nitrate hexahydrate and 1.455g of cobalt nitrate hexahydrate were dissolved in 50ml of methanol to obtain solution A; 3.284g of 2-methylimidazole was dissolved in 50ml of methanol, and 0.16g of commercial graphene was ultrasonically dispersed to obtain Solution B, pour solution A into solution B, mechanically stir at room temperature for 1 hour, then let it stand for half a day, vacuum filter and dry the solid obtained as zinc, cobalt-bimetallic organic framework @ graphene precursor; will get The precursor was calcined under an argon atmosphere at 1050°C for 2h, and the heating rate was 5°C / min; After drying at ℃ for 12 h, a cobalt / nitrogen double-doped porous carbon@graphene (Co-N-C@RGO) composite was obtained. The specific surface area of the resulting material is less than 800m 2 / g, wherein the content of Co is about 2.4At%, and the content of N is about 15At%.

[0119] The obtained Co-N-C@RGO composite material was mixed with the binder PVDF at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com