A novel pultrude process and product thereof

A pultrusion process and finished product technology, applied in the field of composite material profile production, can solve problems such as easy generation of waste, reduced product strength, time-consuming and labor-intensive, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

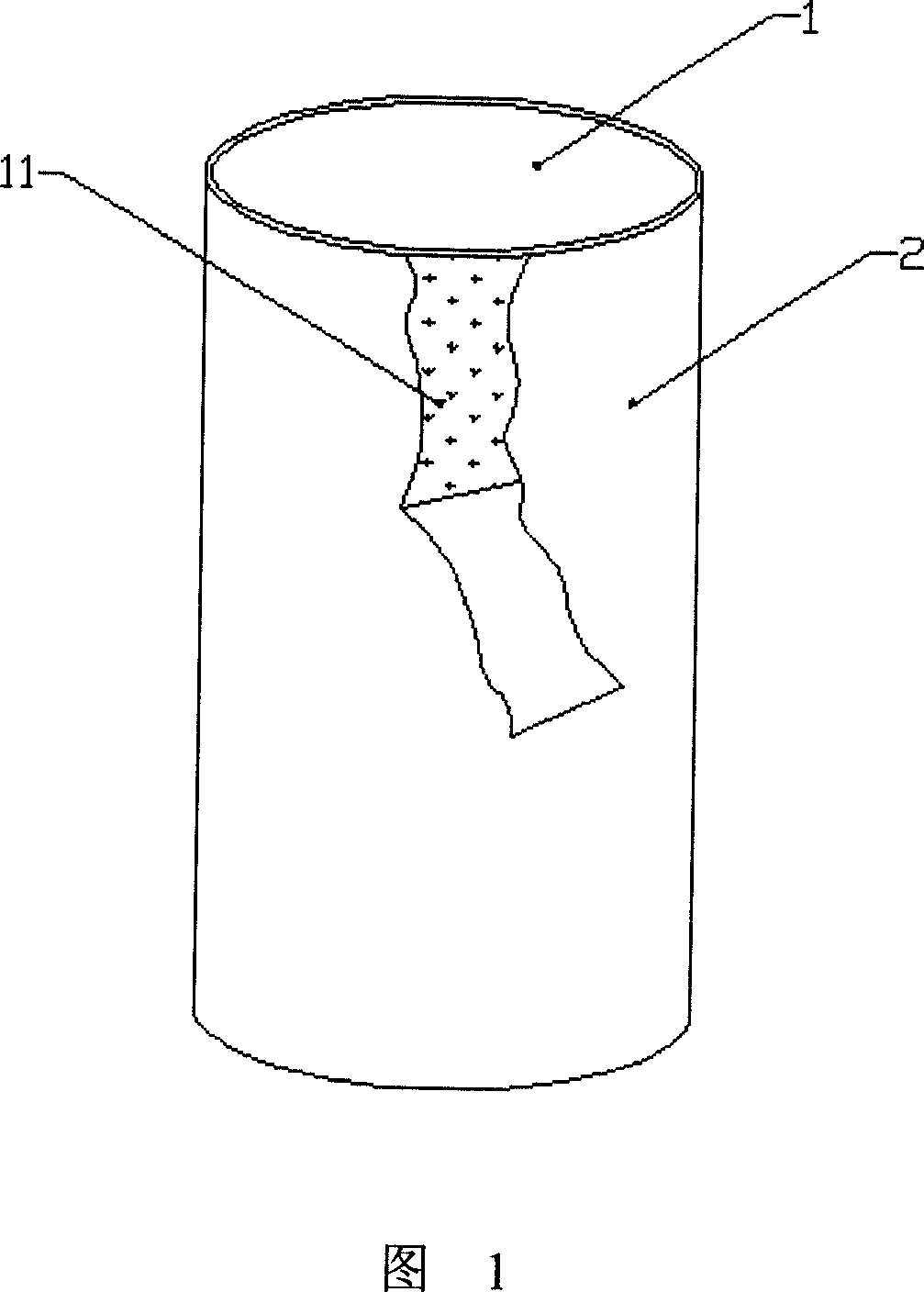

[0017] The present invention is a new pultrusion process, which mainly includes the following sequential steps: first arrange reinforcement materials, such as fiber yarns, felts, surface mats, etc., impregnate them with resin, then preform them through a preforming die, and Add peelable materials, such as release cloth, to the surface of the preformed semi-finished product, and then send it into the mold for extrusion molding and heat curing, and finally pull it to the cutting device through the traction mechanism, and cut it according to the size required by production to obtain the finished product . The finished product includes a pultruded main body and a peelable material layer on the outer surface of the main body. Since the peelable material itself has a certain roughness, the surface of the main body in contact with the peelable material layer forms a uniform rough surface.

[0018] The transmission system of the reinforced fiber yarn adopts the yarn inlet frame, the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com