Silane coupling agent containing cyanogen group and preparation method of silane coupling agent

The technology of silane coupling agent and alkenyl siloxane is applied in the field of cyano group-containing silane coupling agent and its preparation. Efficiency improvement, short response time, effect of improving interfacial bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The cyano-containing silane coupling agent provided in this embodiment is synthesized from the following materials:

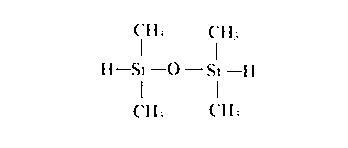

[0032] The molecular structural formula of hydrogen-containing oligosiloxane (A) is:

[0033]

[0034] The molar mass of the reaction is 1mol;

[0035] The alkenyl-containing siloxane (B) is vinyltriethoxysilane, and the reaction molar weight is 1mol;

[0036] A class of compound (C) containing cyano and alkenyl is allyl cyanide, and the reaction molar weight is 1mol;

[0037] Platinum catalyst at 20 ppm calculated as platinum atoms.

[0038] Add the above-mentioned alkenyl-containing siloxane (B) component dropwise to the hydrogen-containing oligosiloxane (A) to which an appropriate amount of catalyst has been added to react to synthesize an intermediate product, add pentane as a solvent, and the reaction temperature is 45-55 °C , the reaction time is 2.5 h; then the obtained intermediate product is added dropwise to the cyano- and alkenyl-contai...

Embodiment 2

[0041] The cyano-containing silane coupling agent provided in this embodiment is synthesized from the following materials:

[0042] The molecular structural formula of hydrogen-containing oligosiloxane (A) is:

[0043]

[0044] The molar mass of the reaction is 1 mol;

[0045] A class of compound (C) containing cyano and alkenyl is allyl cyanide, and the reaction molar weight is 2 mol;

[0046] Platinum catalyst at 45 ppm calculated as platinum atoms.

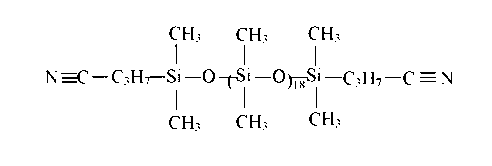

[0047] The above-mentioned hydrogen-containing oligosiloxane (A) is added dropwise to a class of compounds (C) containing cyano and alkenyl groups to which an appropriate amount of catalyst has been added to react and synthesize the target product. The reaction temperature is 80-90 ° C, and the reaction The time is 30 minutes. Synthesize the target product:

[0048]

Embodiment 3

[0050] The cyano-containing silane coupling agent provided in this embodiment is synthesized from the following materials:

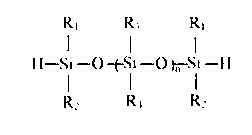

[0051] The molecular structural formula of hydrogen-containing oligosiloxane (A) is:

[0052]

[0053] The molar mass of the reaction is 1mol;

[0054] The alkenyl-containing siloxane (B) is methacryloxypropyltrimethoxysilane, and the reaction molar weight is 1mol;

[0055] A class of compound (C) containing cyano and alkenyl is cyclohexyl cyanoacrylate, and the reaction molar weight is 1mol;

[0056] Platinum catalyst at 10 ppm calculated as platinum atoms.

[0057] Add the above-mentioned alkenyl-containing siloxane (B) component dropwise to the hydrogen-containing oligosiloxane (A) to which an appropriate amount of catalyst has been added to react to synthesize an intermediate product, add n-hexane as a solvent, and the reaction temperature is 65-75 °C , the reaction time is 1 h; then the obtained intermediate product is added dropwise to a class ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com